Some of you have seen some posts about a project I haven't been making much note of, but it's been consuming a bit of time and deserves some mention. I usually don't post about these big projects while they are in process but this one needs to be mentioned. A forum member here asked me to build them a E91 S65 Touring. That project has been a monumental task. The amount of work needed to adapt the two cars in the way I do here is incredibly intense, the work can't be put into a single post here so I'll add an additional post or maybe start it's own thread (even though it's not a E46 some info will carry over for those wanting to S65 sway their E46).

But moving on I've also been working on a S54/E30M3. The car came to me and has been sitting here for a bit, but we finally got it together. It was previously a running and driving car but I was told there were some errors in the previous work which led to a complete engine failure on track. The engine got pulled and then the car was never put back together. We finally got a good donor S54 and I sorted out the swap to the customers liking.

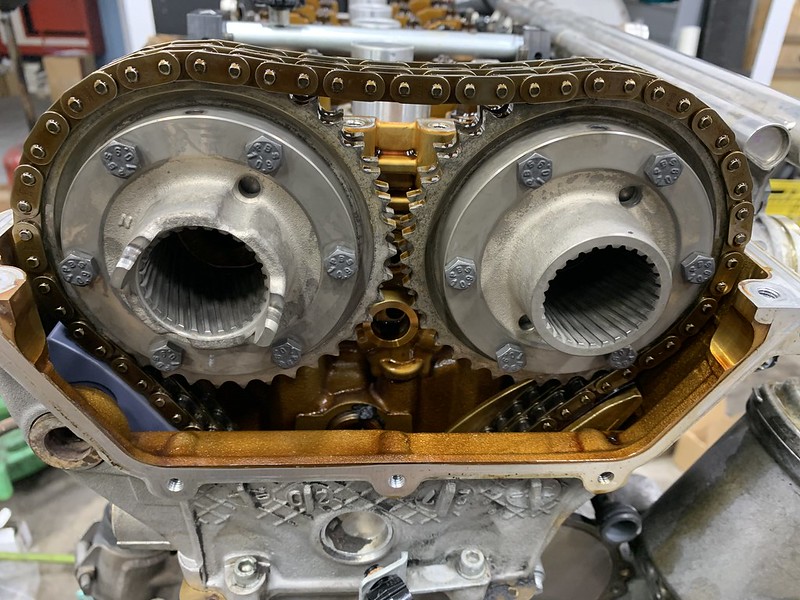

The engine had the rod bearings and vanos previously done, but the vanos disc was supposedly not modified for smaller tab holes. So that was on the list, but luckily it had been done already.

There are a couple ways to install a S54 in this chassis the main (2) options being to modify the S54 dual sump pan and cross member or use an E34 front sump oil pan. This car was setup for the E34 pan and while swapping it over discovered the baffle kit was in need of a bit of repair.

Engine cleaned up and about ready to set on the subframe.

Tilton race clutch going on, I had to source the correct flywheel bolts and Tilton was fantastic to get that sorted out, very pleased.

Engine in.

And running.

Pretty much done, just waiting on an air filter.

Cleaned up and just about ready to go back home.

Video of it in action, click the pic.

We had a storm a few weeks (months?) back and our big Ash tree got strut by lightening. Ended up deciding to take it down.

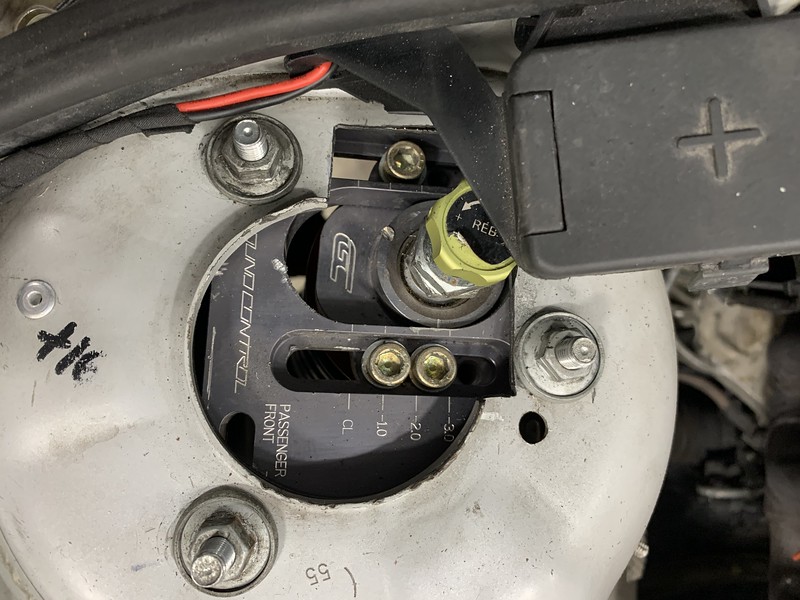

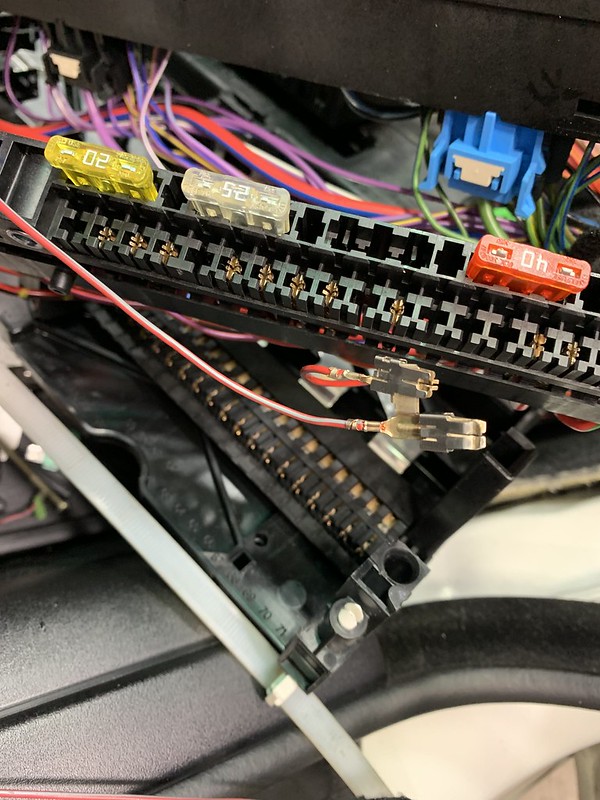

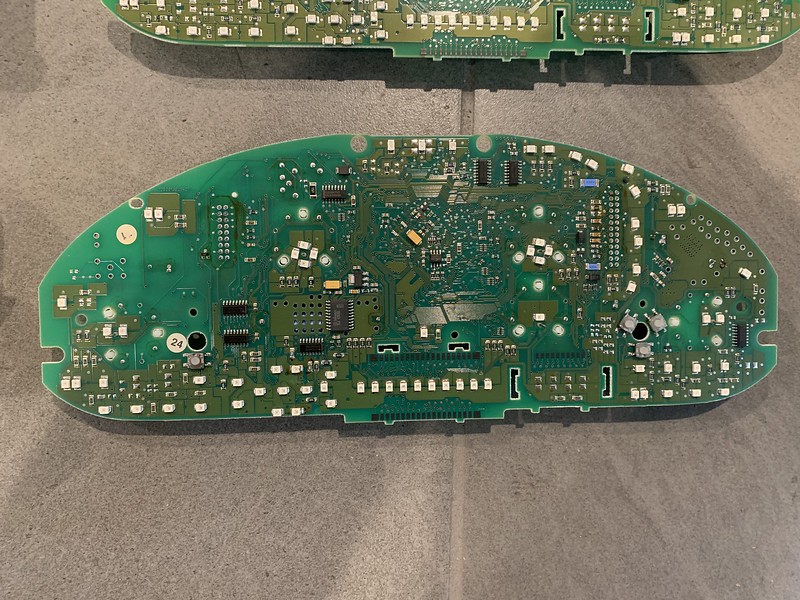

Juliann's Frankenwagon was back for some more sorting out. The car has always had a battery, since the car was built always. I finally decided I was going to figure it out at all costs lol. After seting the car up for a battery draw test I confirmed the car was pulling nearly an Amp of power when turned off. After some diag I found the DME main relay was staying energized. After a bunch more testing I discovered the DSC was involved in the issue as it would turn off the relay if the DSC was unplugged. Her car is the definition of a Frankenstein, body harness form a MK60 touring (her's is a '00 MY), LCM from a coupe, Cluster from a LCI M3, EWS/DME from a early M3, etc etc. Ultimately the problem was the car was not coded properly. Fixing date codes in modules told the DME to look for a MK60 DSC instead of the MK20 it thought was installed. Such a simple fix caused a huge issue. This process took about 20+ hours of diagnosing to figure out! Next up she has a rebuild final drive en route from DiffsOnline to be installed next week.

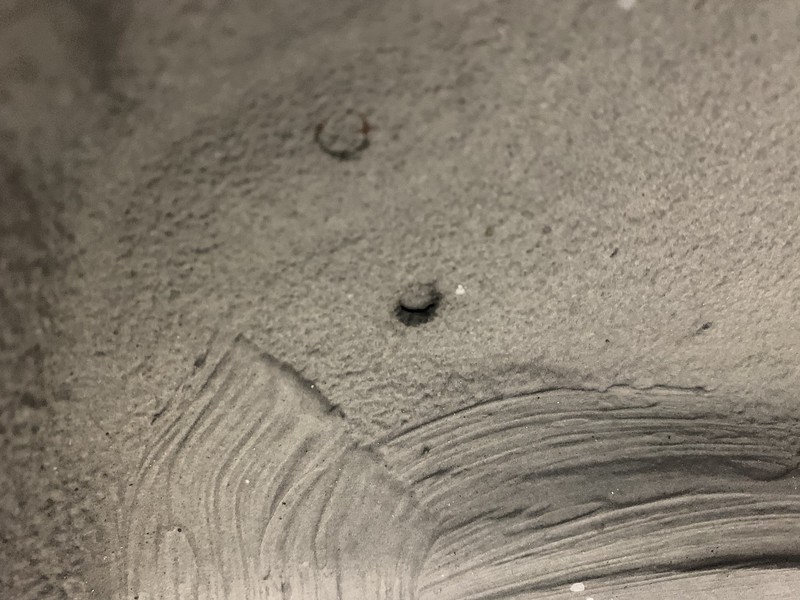

Next, I have an M3 in for a clutch job that turned into a full blown sorting. As part of that I found the RACP had been poorly repaired and needed to be gone over. I found it had plates installed already but it was a very weak attempt at fixing the issue. The plan was to get everything apart and assess the state of the car at that point. The car has a blower on it and is primarily a HPDE car so we need to make sure it was as solid as we can get. Once apart the plates seemed to be installed well enough that it would do more harm than good to remove and replace. So I fixed some welds for them and then repaired a ton of cracks, stitch welded the spring perches and RTAB pockets. Every common place and then some had damage, wheel well arch, spring pocket, popped spot welds, cracks, etc.

The topside was reinforced using the CMP AutoEngineering Top Side and Frt Ext Kit. This is a significant amount of work, but hopefully will be the last time he every has to think about a RACP issue. The previous repair was such a sad attempt. They missed lots of cracks, popped spot welds and then I think they glued this lumber down to hide that, IDK?

This project is still on going but should be wrapping up soon.

And now what everyone is waiting for, lol. As you may recall I have entered DragWeek 2020. The plan is to take my Mustang, it's recently appeared in the background of some of my pics. I bought this mustang back in '07 I believe. At the time it had a supercharged 331ci SBF and a T5. It ran low 11s with a bad 60' and I drove it a bunch, then hurt the motor. I lived in an apartment at the time, then moved a bunch and had nowhere to work on it. Once I built the shop I started on it again with a Pontiac engine. That project fizzled out when I decided to open the business and needed the cash so I sold the engine to pay for a fence.

Fast forward to this year and I made a commitment to myself to do #dragweek this year and the only "fitting" car I have is the Mustang. So it was just a rolling chassis and needed a powerplant. I still have the SBF but didn't think it made sense considering my current enthusiasm for BMWs. The only option that makes sense is a BMW engine. I went back and forth between a few options including a single turbo N54, but settled on a M52B28, which came from an E36 328i.

Now that on it's own wouldn't make enough power to do the Mustang justice, so I am adding a turbo to it.

Next for a transmission, I really didn't want a manual for no other reason than I just didn't. BMW autos aren't a good fit for this option and a 4L80e would work but is a bit clunky. The only choice that makes sense is the DCT out of a E92 335is.

I really wanted to do this work myself, but I am way to busy with customer work. Aside from that my fabricating ability is not as strong as my BMW ability and it would just take to much time. I am going to be pressed for time with this project anways so I decided to farm this work out. Another customer hooked me up with a chassis builder in town here and we hashed out a plan. The car is currently at his shop getting the engine and trans mounts made, full exhaust including down pipe and then all the turbo plumbing in and out of the intercooler.

Leave a comment: