I don't trust a M54 (or many engines for that matter) that I can't hear run so we sourced a 330 auto convertible and parted it out for it's heart and then did the normal maintenance you would do on an M54 engine.

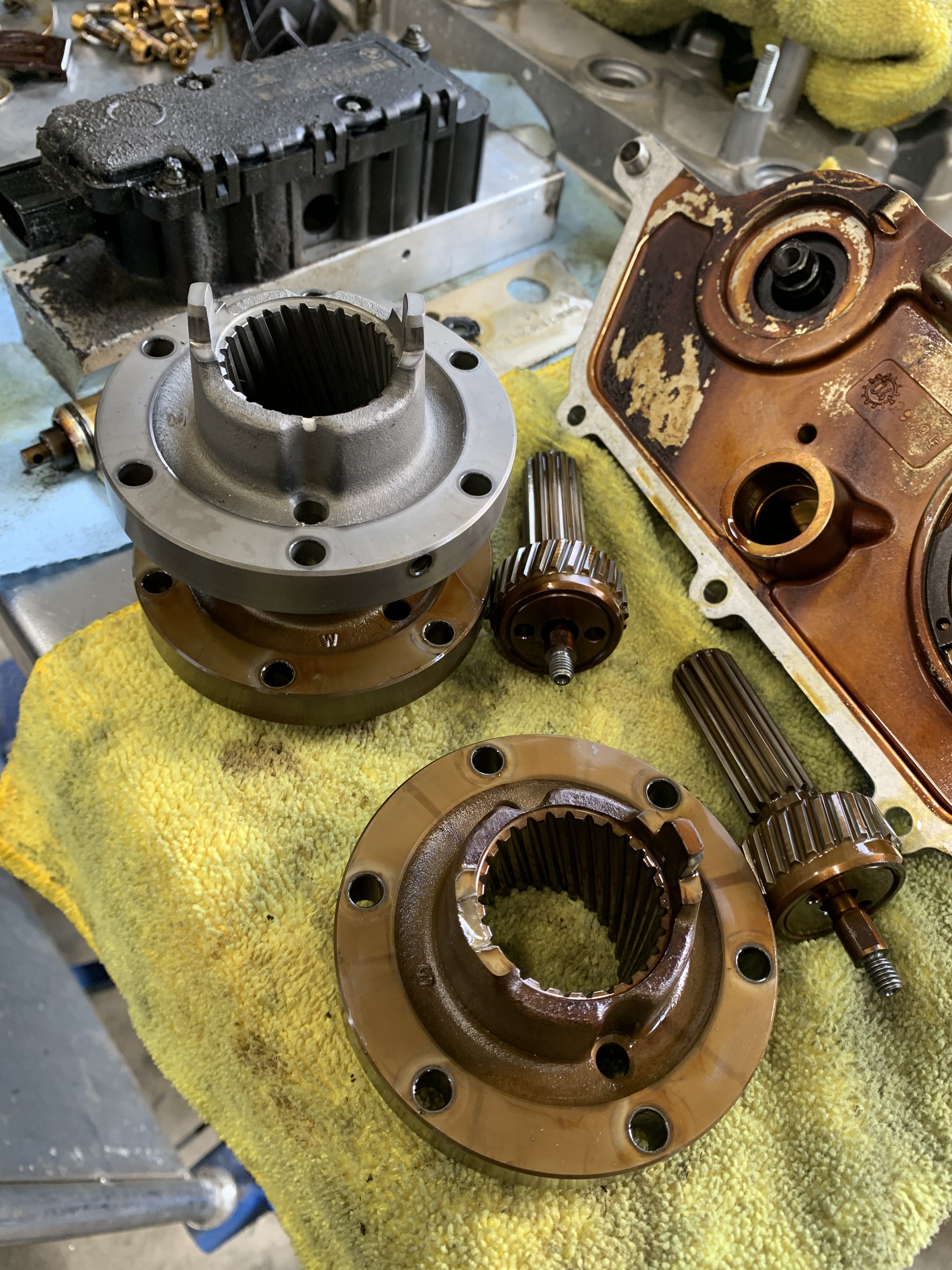

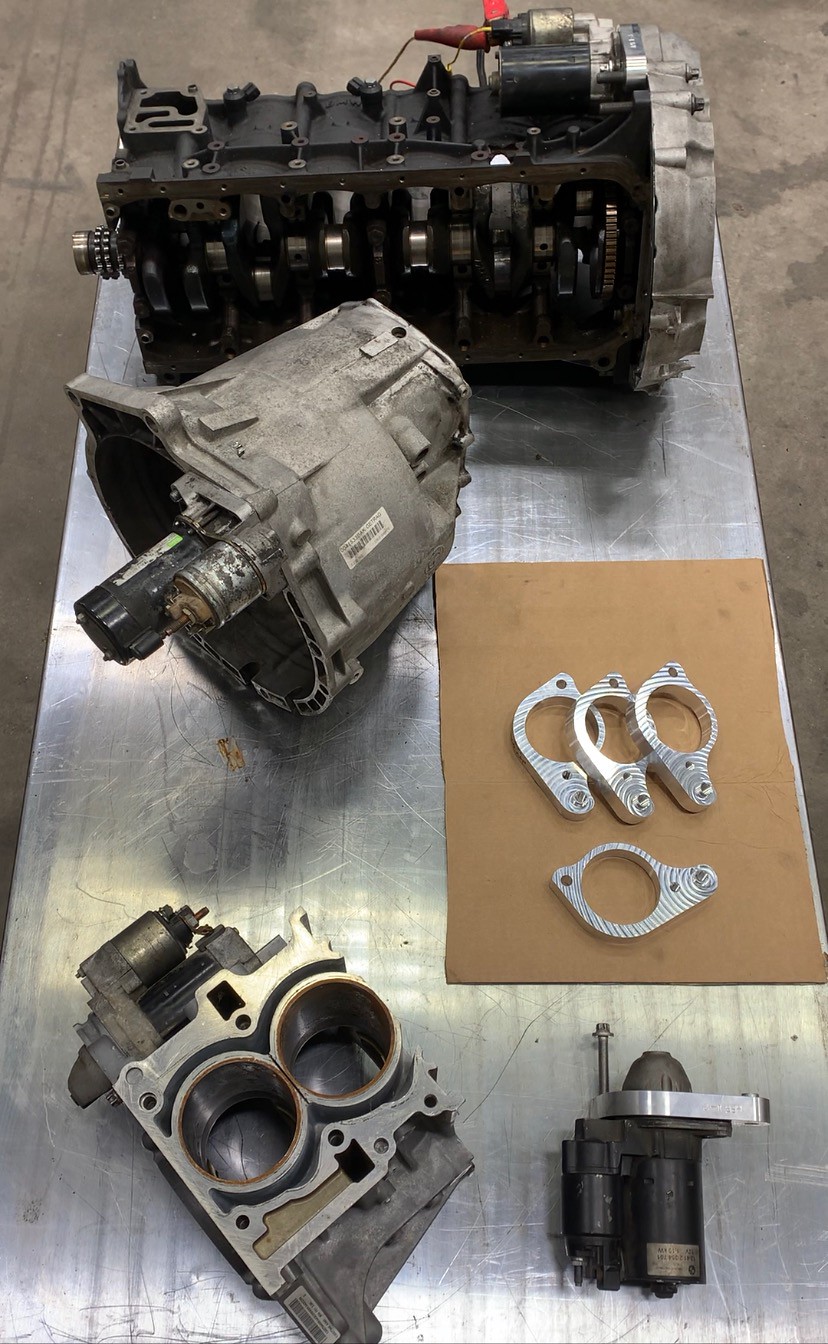

The GSR oil pump had eaten some metal and we felt it should be addressed, most of the parts were ok, but the housing needed to be replaced. To use the GSR parts the oil pump housing has to be modified, unfortunately we couldn't get the specs on the modification but with a little trial and error and reverse engineering we got if figured out.

Unfortunately the owner decided that he needed to refocus his hobbies and had to let the car go, but the car quickly sold and is somewhere in the NE now and hopefully battling it out with the huge SE46 field those races attract.

After that we had Scott in with his M3 and when it was all said and done we had done the "big 3." Previously you saw the documentation on the bent cam sensor gear, now this is the rest of the project.

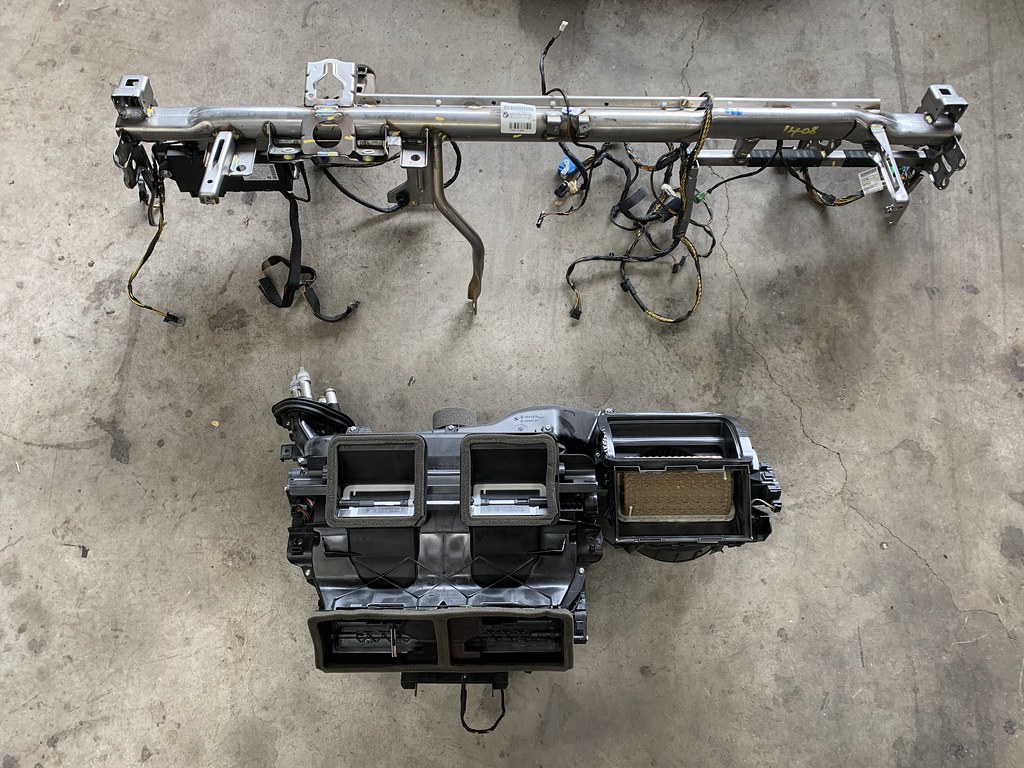

The entire rear was pulled apart, this is 99% of everthing from the transmission backwards comes out of the car. The bottomside of the chassis is power washed, cleaned and inspected. All areas of concern are identified and addressed. CMP Auto Engineering plates are welded in, seam sealed and painted (the color looks off, but in person the match is very close to OE and with everything assembled I don't think most would notice).

The rear suspension was completely refreshed as well.

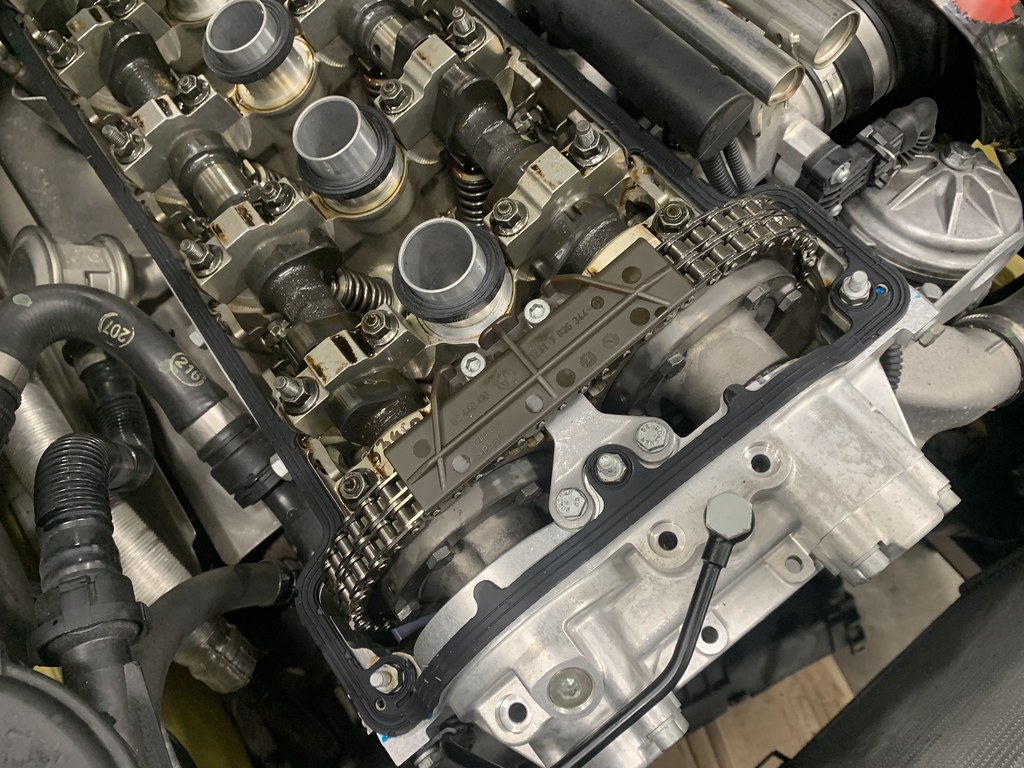

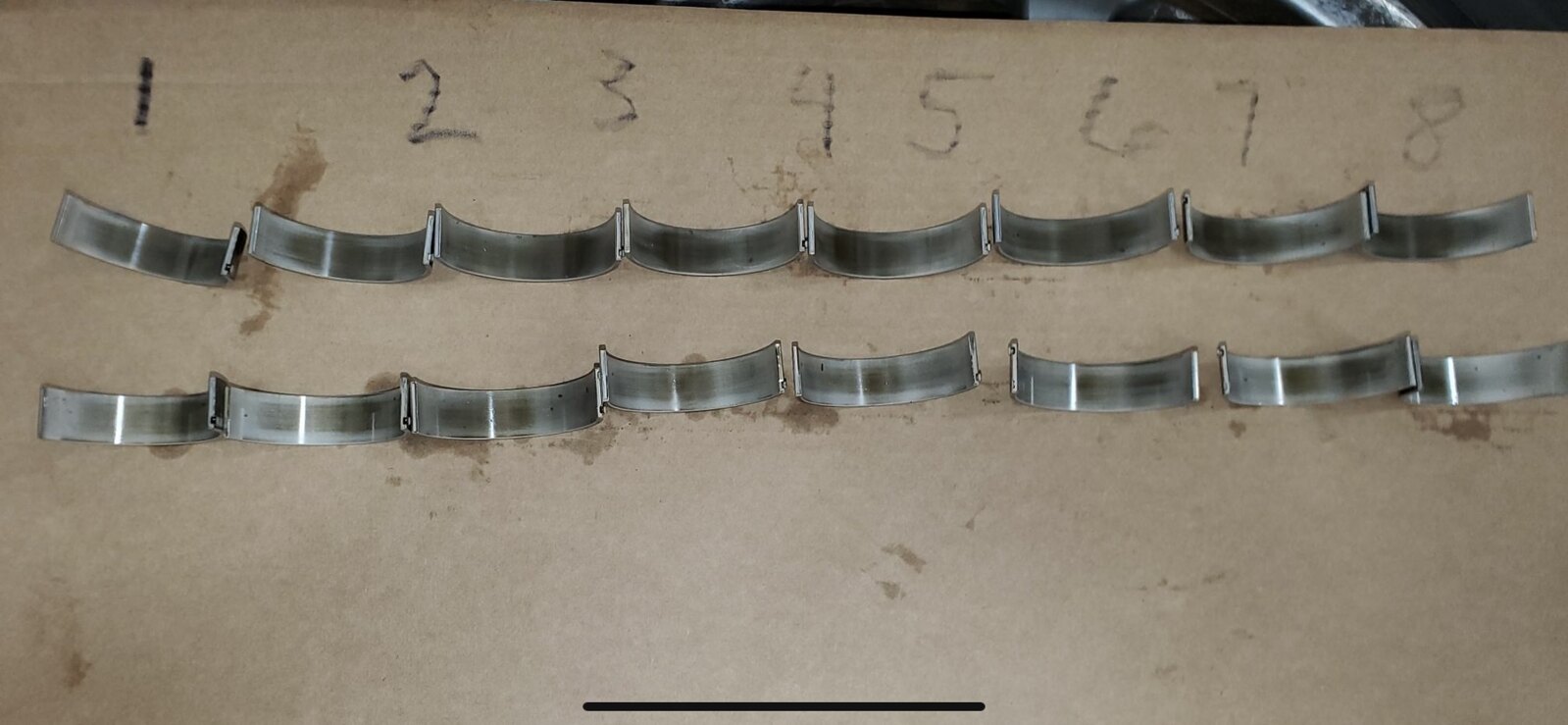

Moving on to the engine bay new rod bearings installed and at 175k if these were original they were in fantastic shape! Along with that we a new oil level sensor, thermostat (and housing), tensioner, engine mounts and stainless steel brake lines.

The oil pump was disassembled, inspected and cleaned.

And to add to the list of cars with front struts assembled this car at least had the correct bumpstops, but they were installed upside down.

Leave a comment: