After having our 4.0 S65 engine sit around for two years we finally got around to disassembling it and will post the teardown here to continue building the knowledge based of the forum

Original blown engine thread:

Some background

We bought the car with 36k miles in 2016 as a dedicated track car. 2011.5 E90 M3 slicktop DCT as the only option, no nav, cloth seats, completely stock at the time.

The first weekend after buying the car we did rod bearings. This is the car of the rod bearing DIY

We kept the engine/exhaust stock for the first ~25k miles and two track seasons, modding brakes & suspension only.

Two track seasons are around 60 track days, but the car is double-teamed so the it sees twice as many sessions per day as a regular car. In other words, the engine has 120 normal track days on it.

After 25k miles and 120 track days days we added an Epic off the shelf tune. We specified a catless tune, however, when the track day rolled around our catless xpipe hadn't arrived so instead we opted to use our ESS HFC Xpipe from our E92.

That xpipe had survived plenty of track days on our other car.

In the first day, first session with the tune and the xpipe on the E90 we did a personal best at WGI with R1 tires (2:06.7) but the engine was 'not running right'. We forfeited the weekend because something was clearly wrong. It is as if the car were running on 7 cylinders, vibrating horribly.

We took it to several mechanics and ended up $10k out of pocket troubleshooting uselessly. The mechanics kept telling us to keep driving the car even though it felt like it was about to tear itself apart. Foolishly we followed their advice.

One day we decided to remove the xpipe and saw the cats were melted, completely blocking one of the banks.

We went back to the stock xpipe and the engine started working again, but now it smoked badly.

A third mechanic identified it as bad valve stem seals, so the engine was dropped and the seals were replaced.

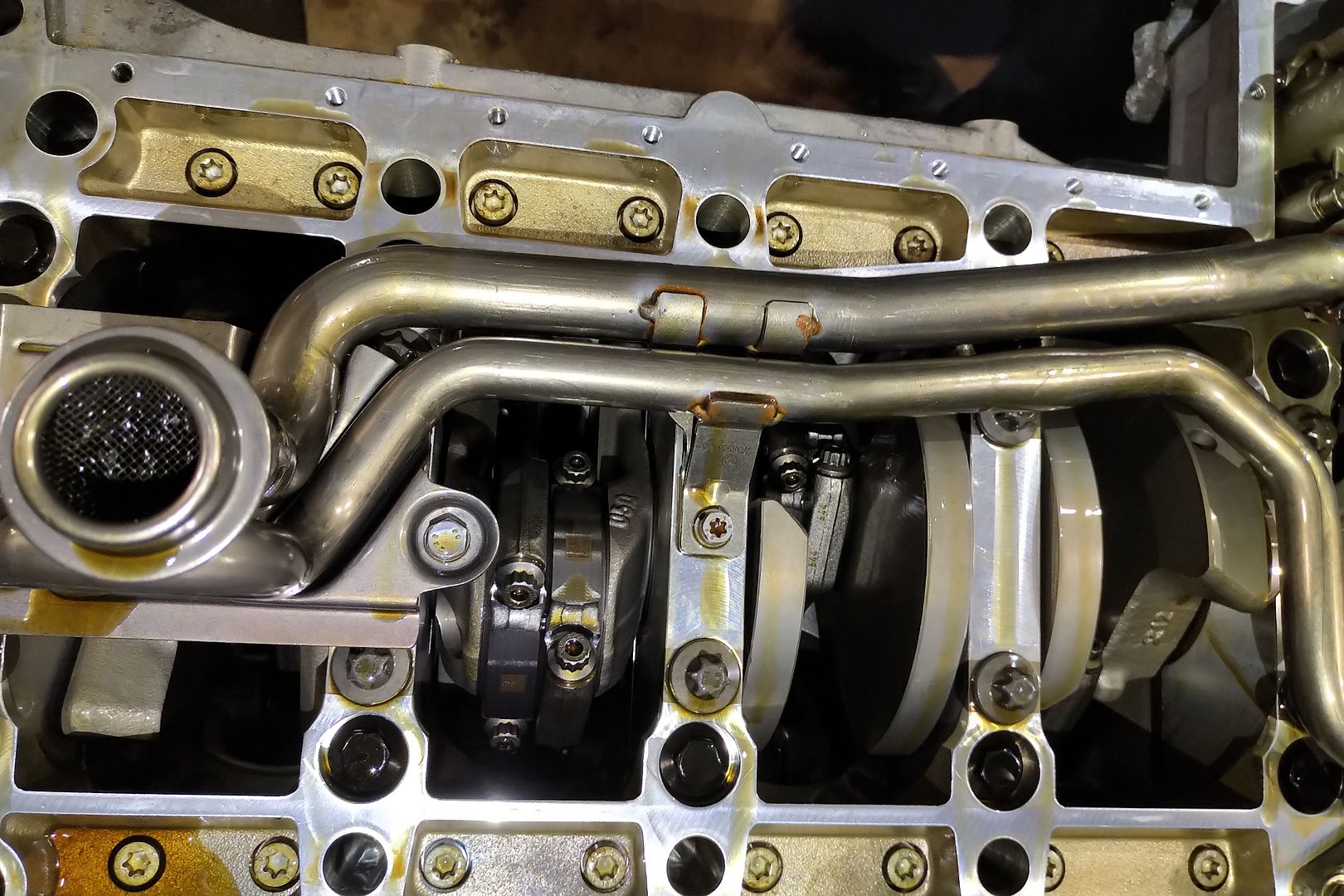

While we were at it, we installed our 284 cams and BE springs as well as the BW LT headers and Karbonius airbox

As there are no off the shelf tunes for 284 cams we did what I had always vowed we wouldn't do and the car went to get custom tuned. RK is in Long Island and is relatively local.

The car went to RK, got tuned on their dyno, put down 412whp and then the engine seized.

Then it sat around for 2 years until we disassembled it

The results are surprising. I'm going to leave a couple posts open to @[AutoTalent](contact:25579), @[kawasaki00](contact:161320) and @[greeneggs](contact:246064) , @[CarBahn Autoworks](contact:372979) , @[deansbimmer](contact:259100) , @[jcolley](contact:25742)

You can see some fluid in the valley of the V8

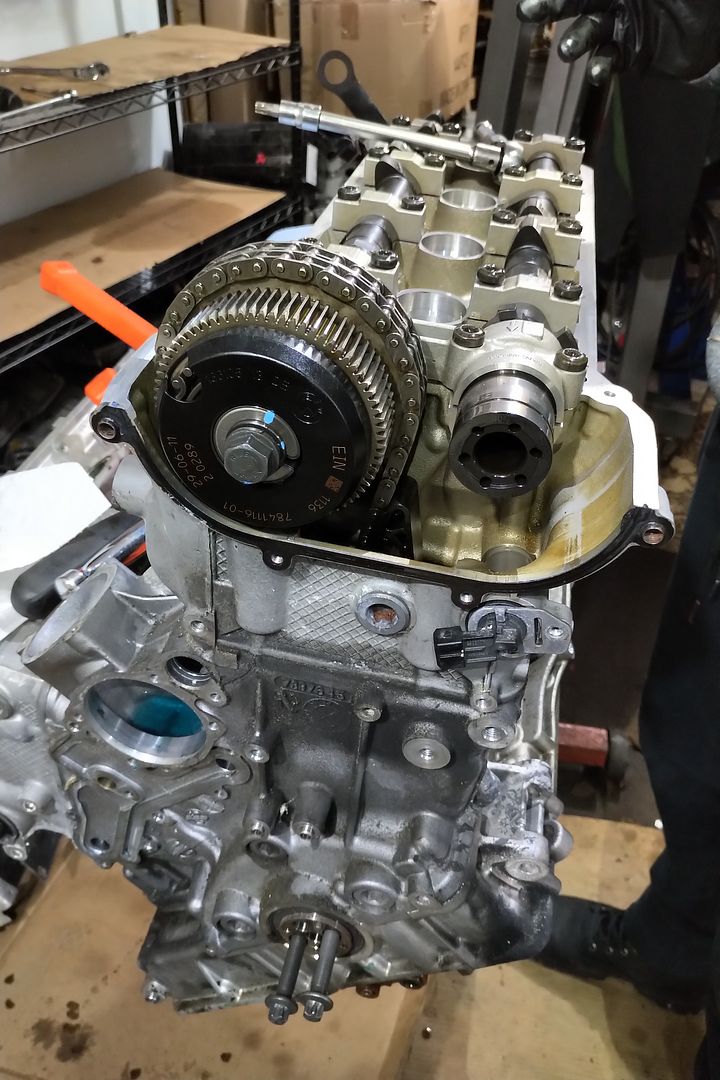

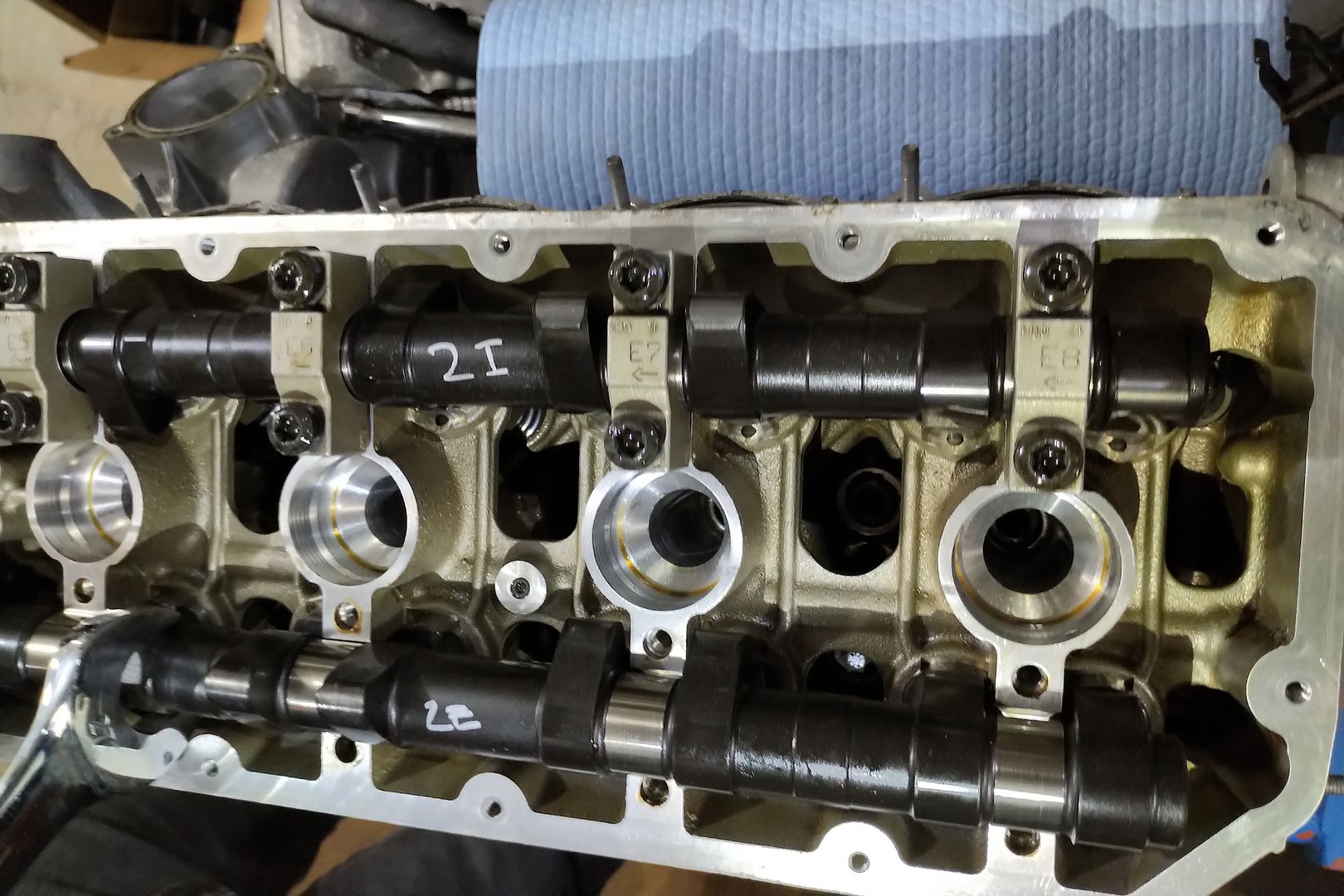

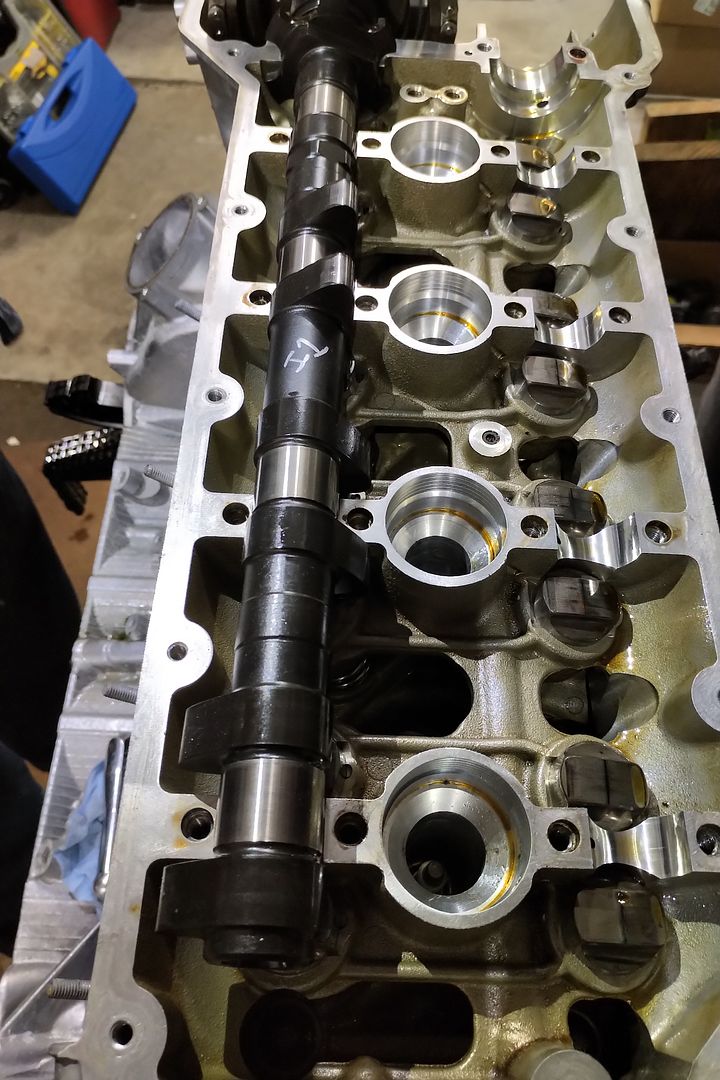

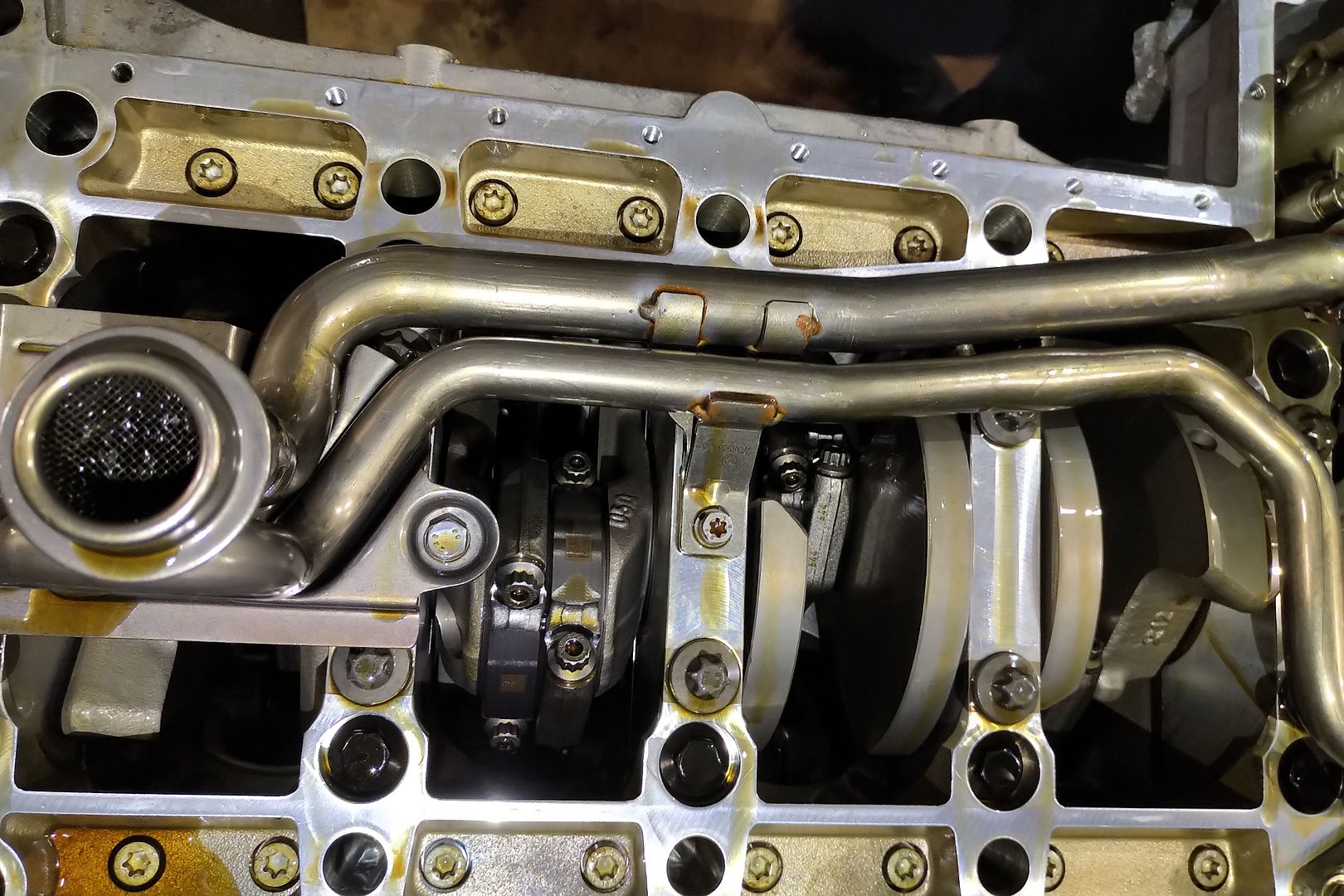

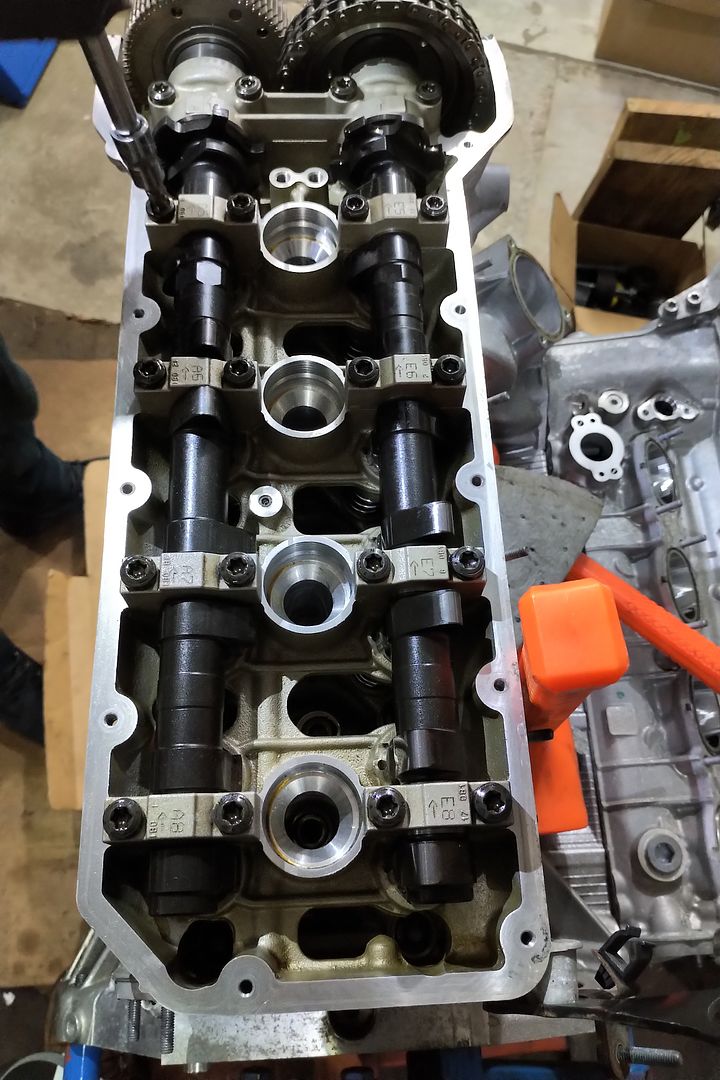

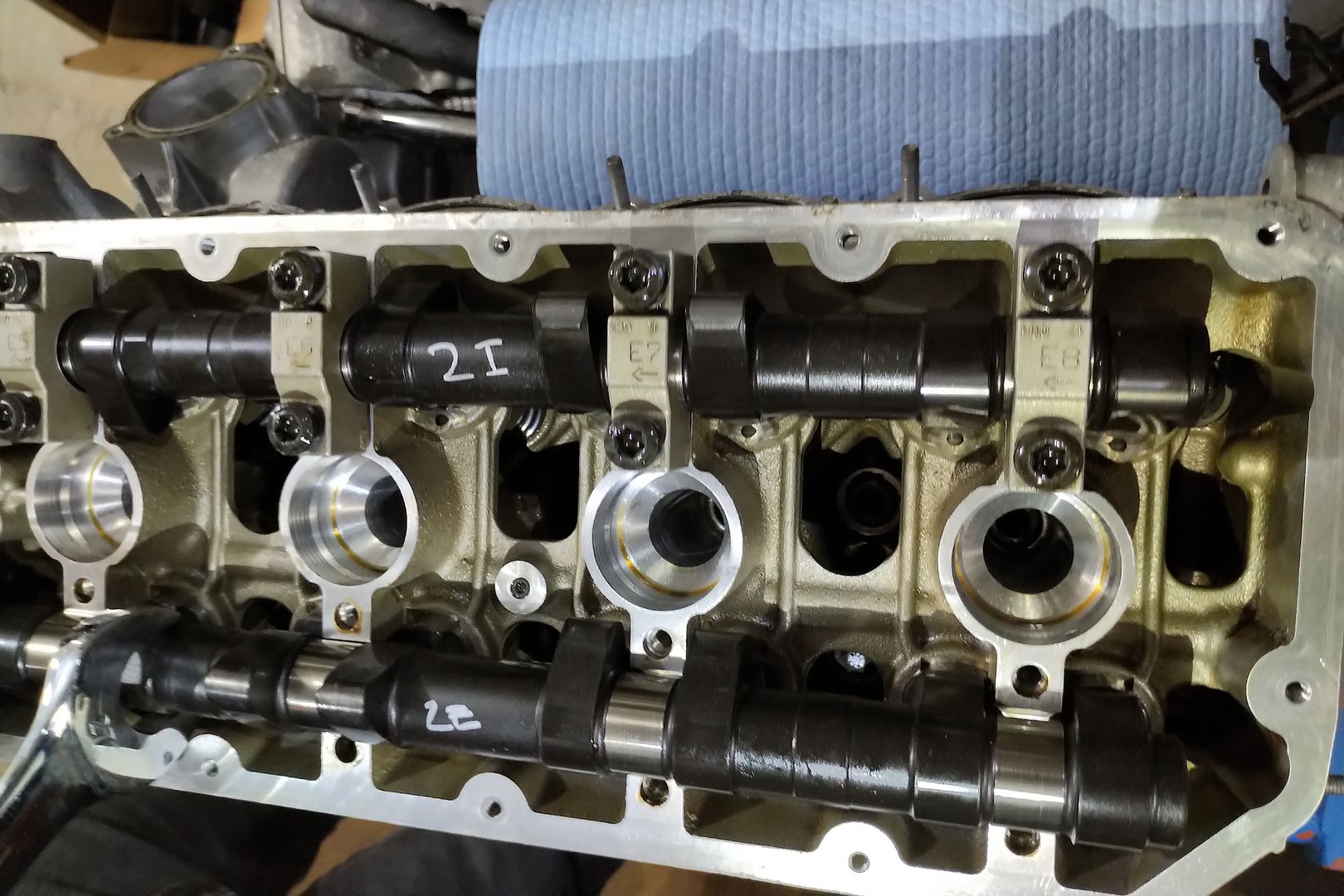

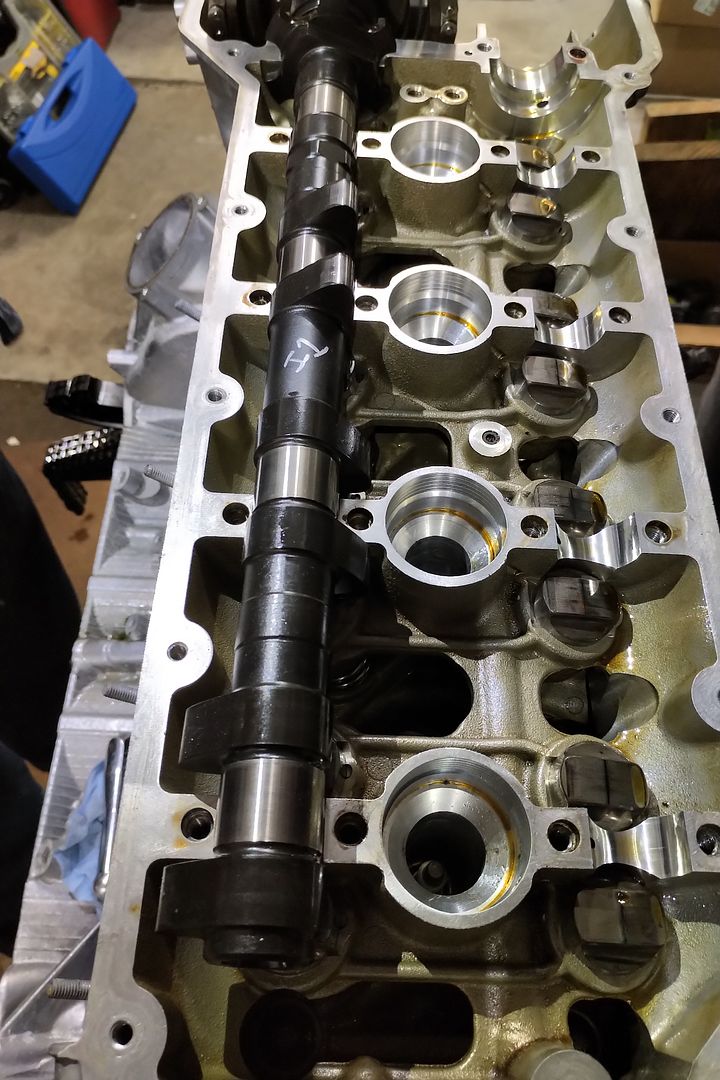

The black 284 cams

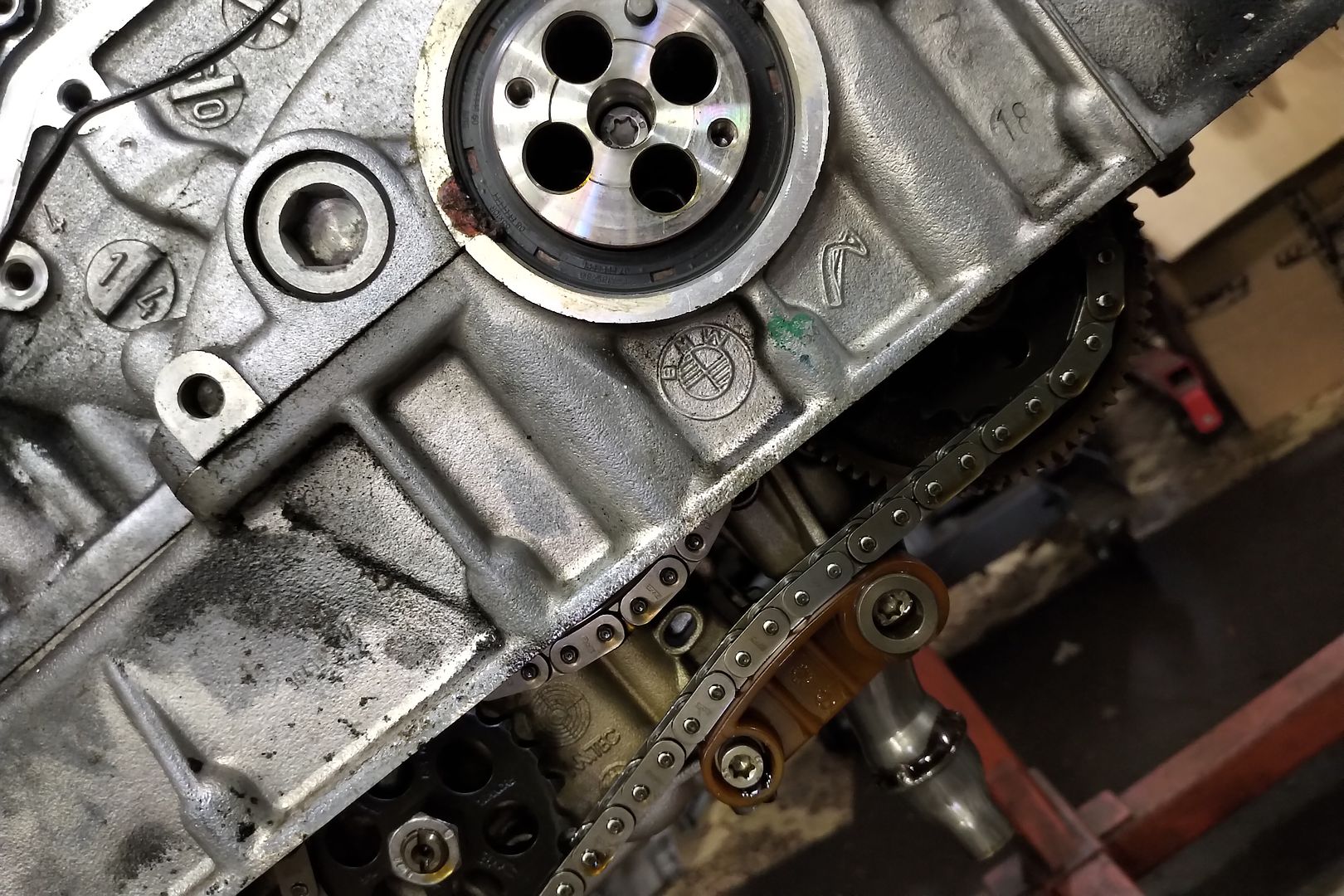

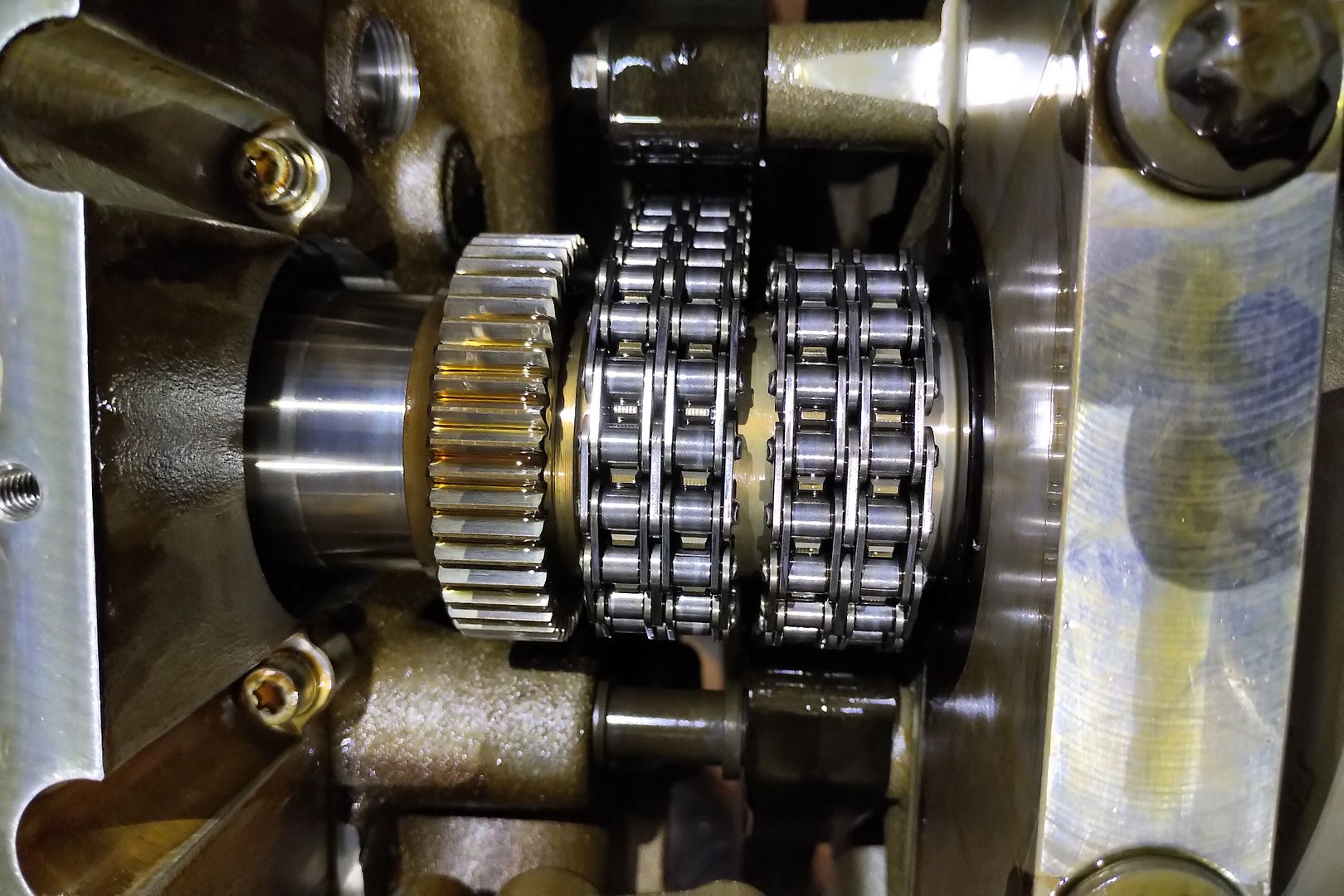

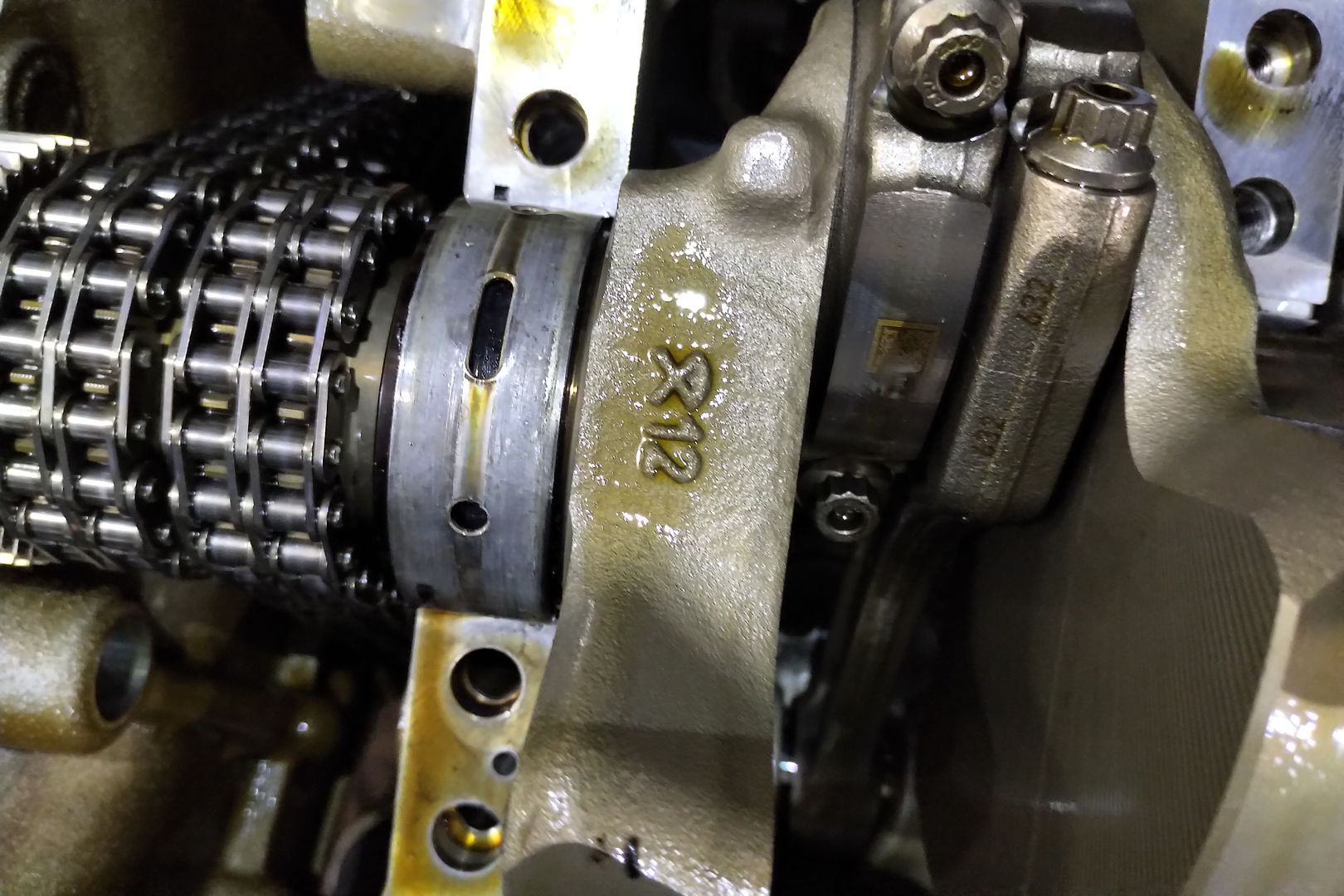

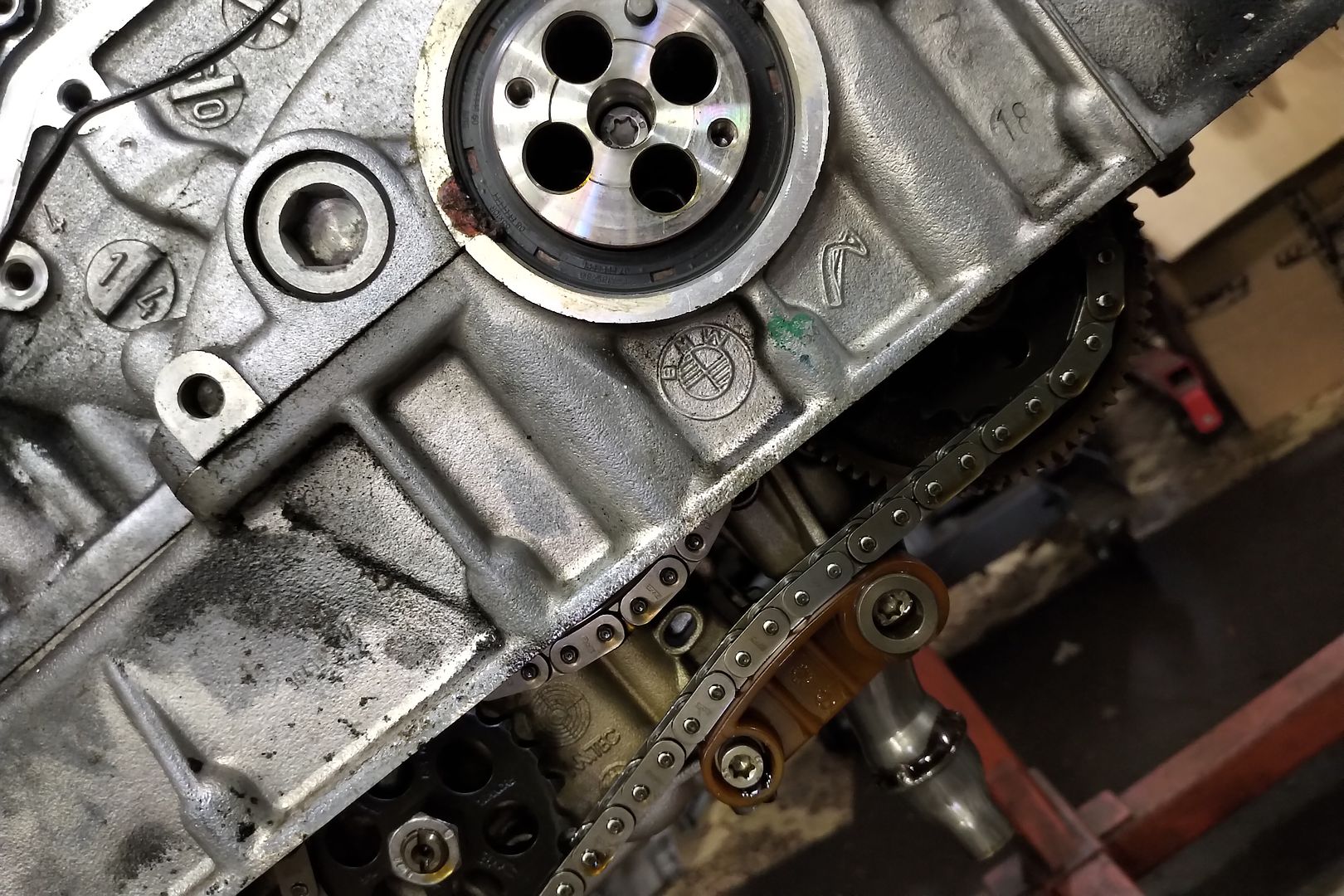

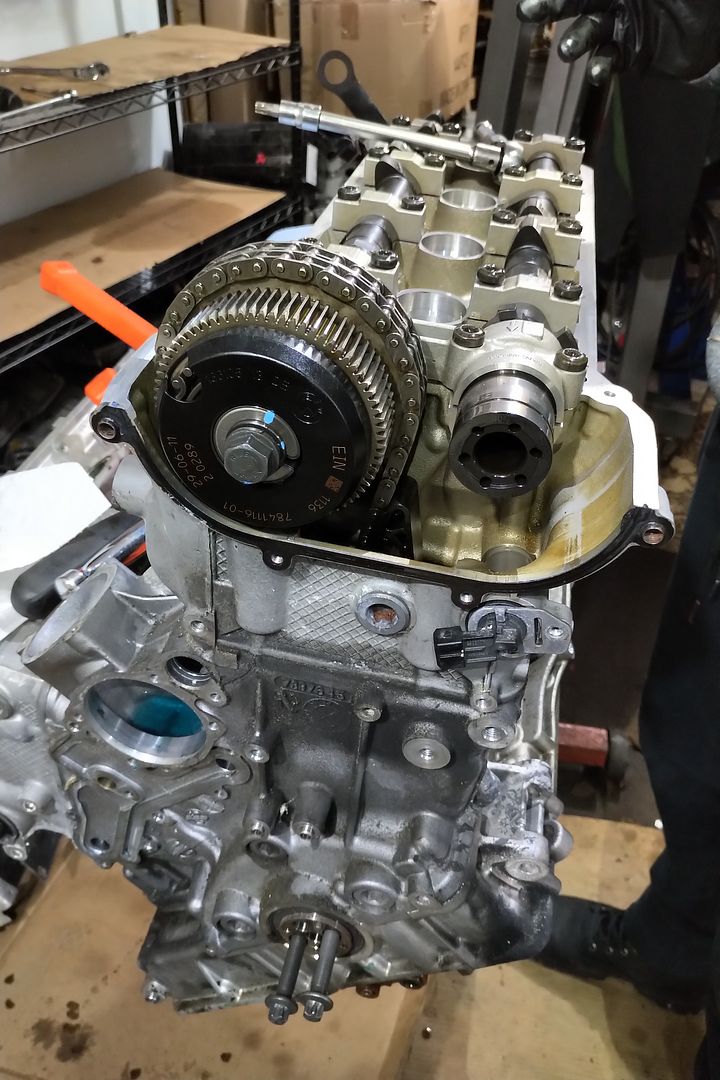

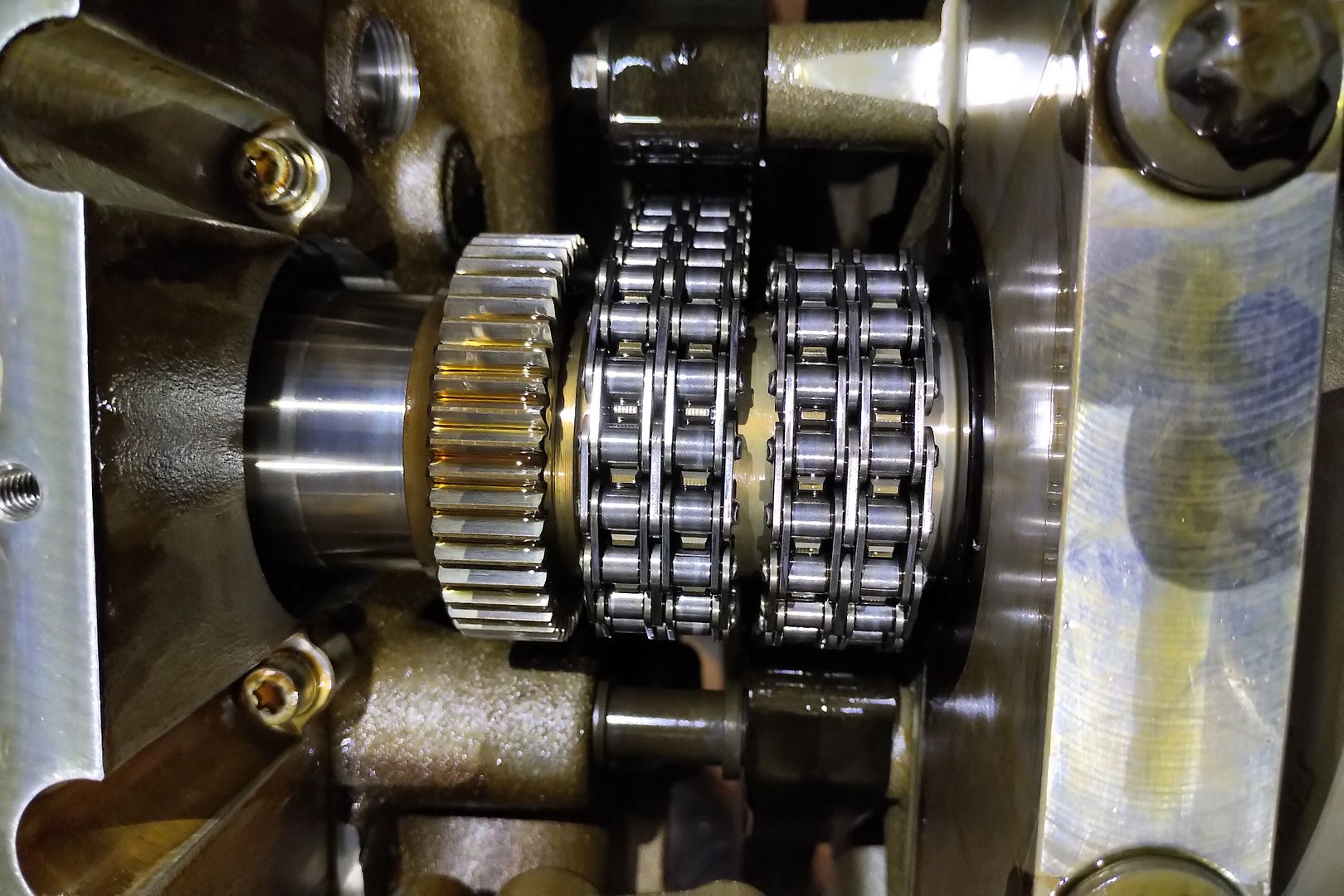

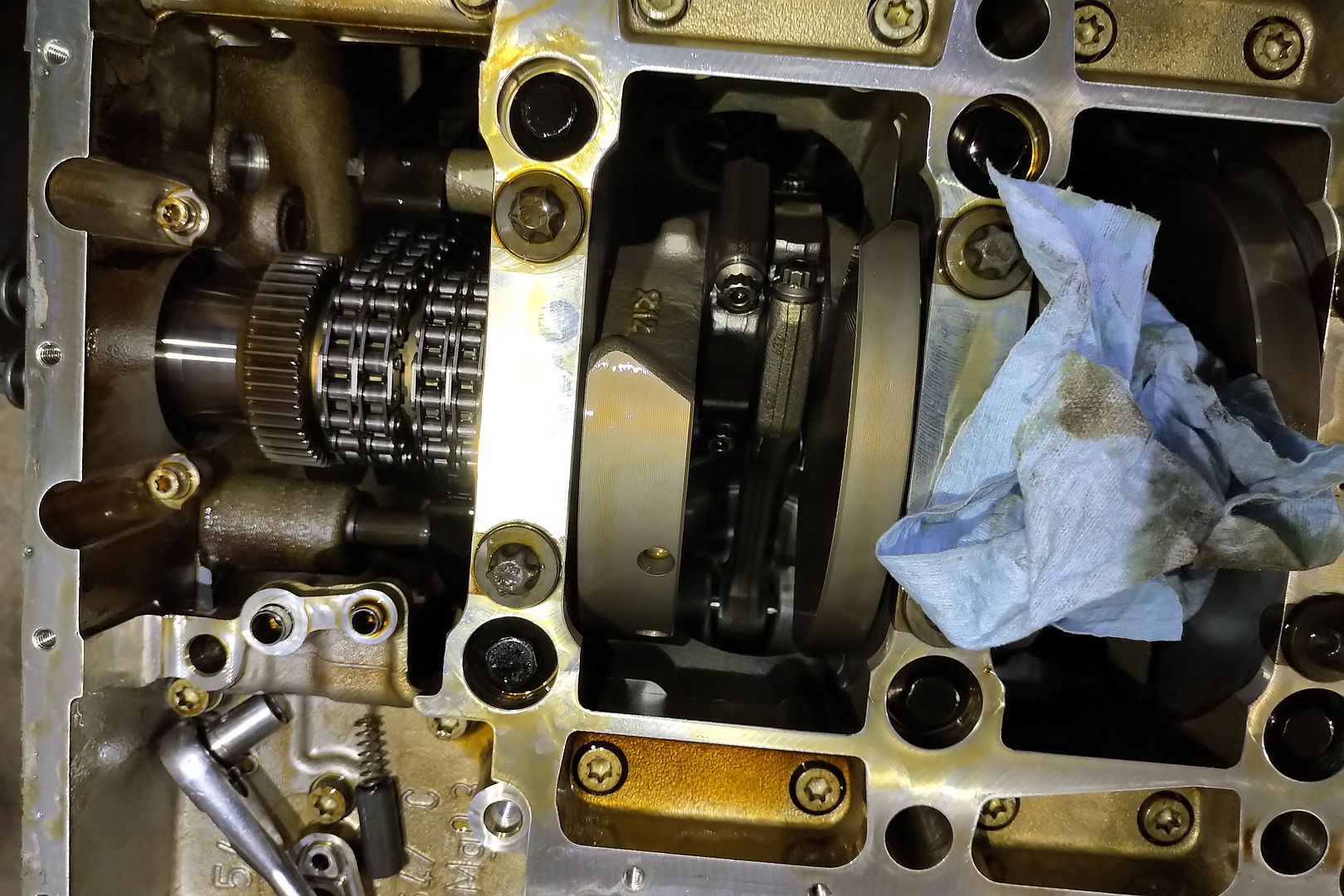

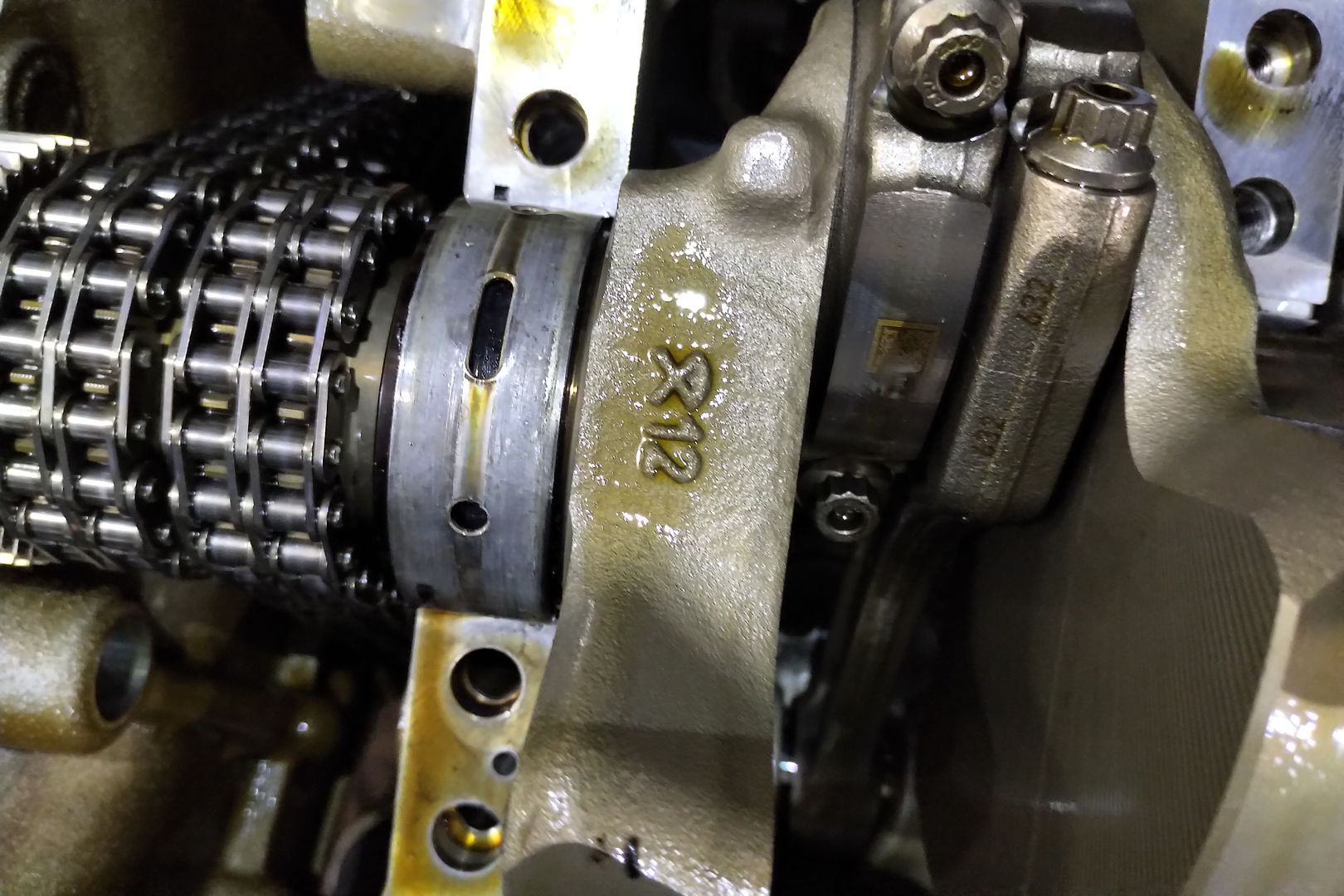

Vanos unit

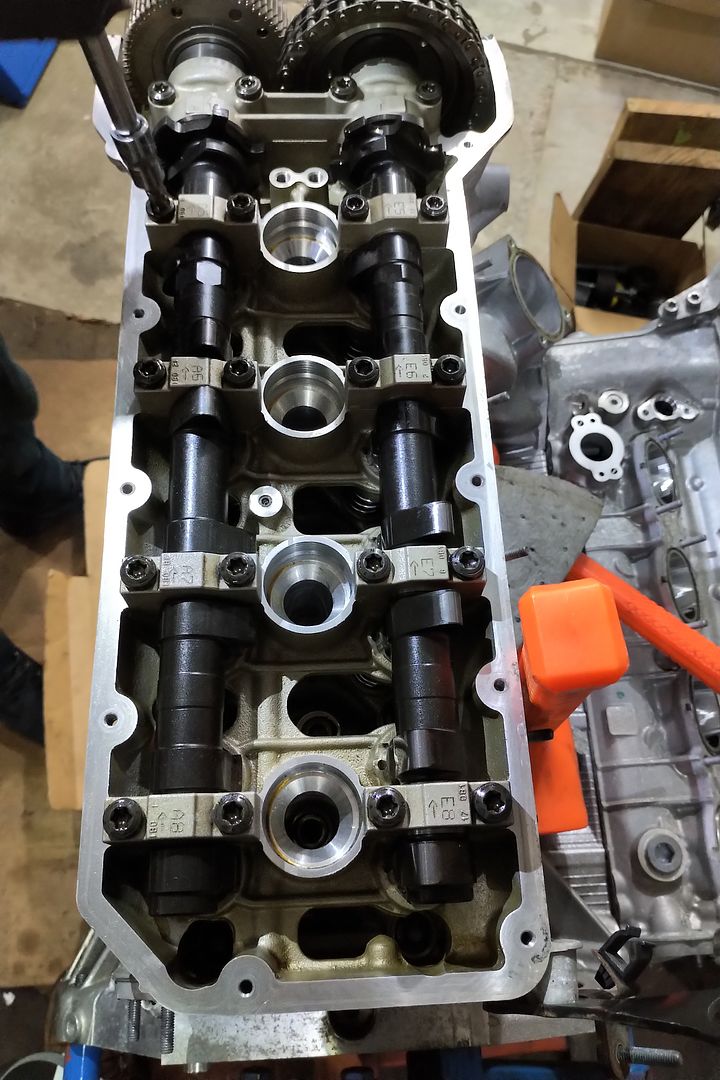

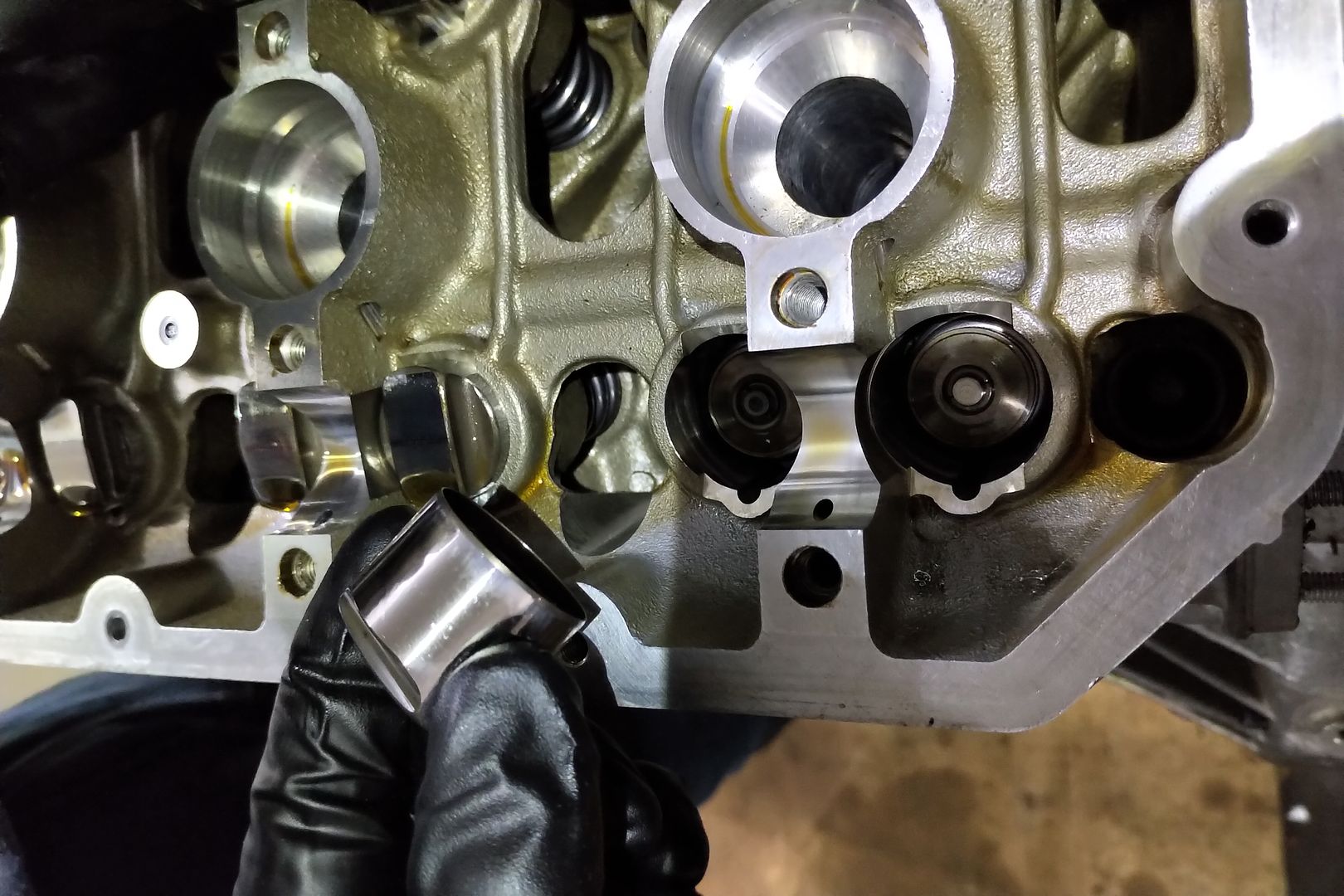

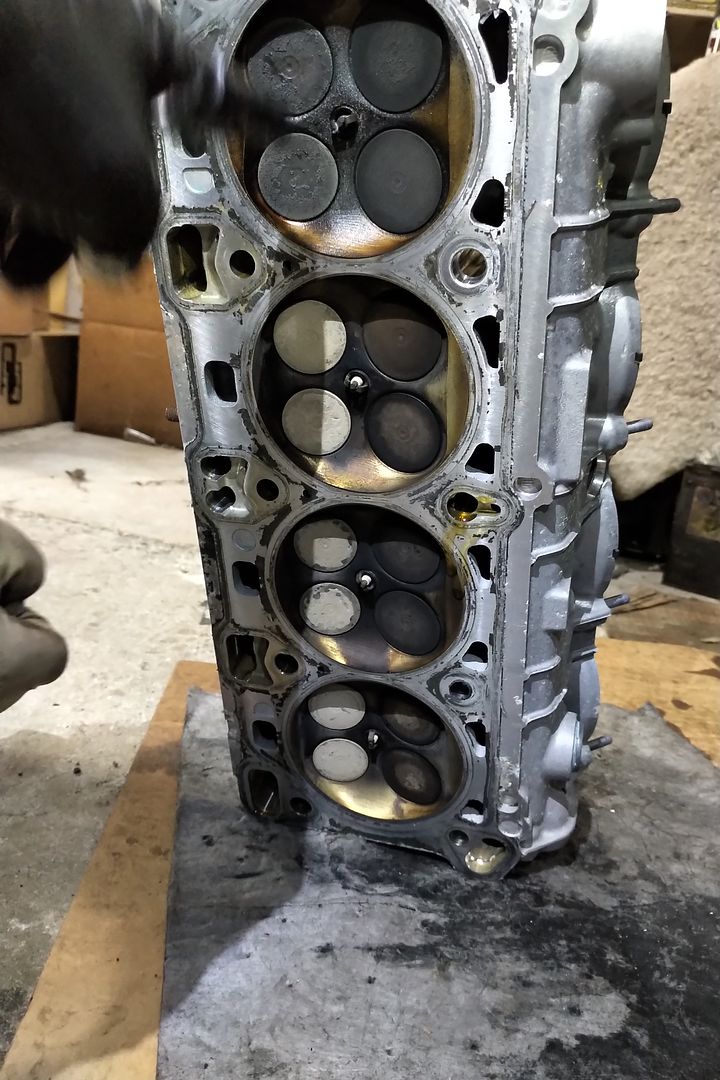

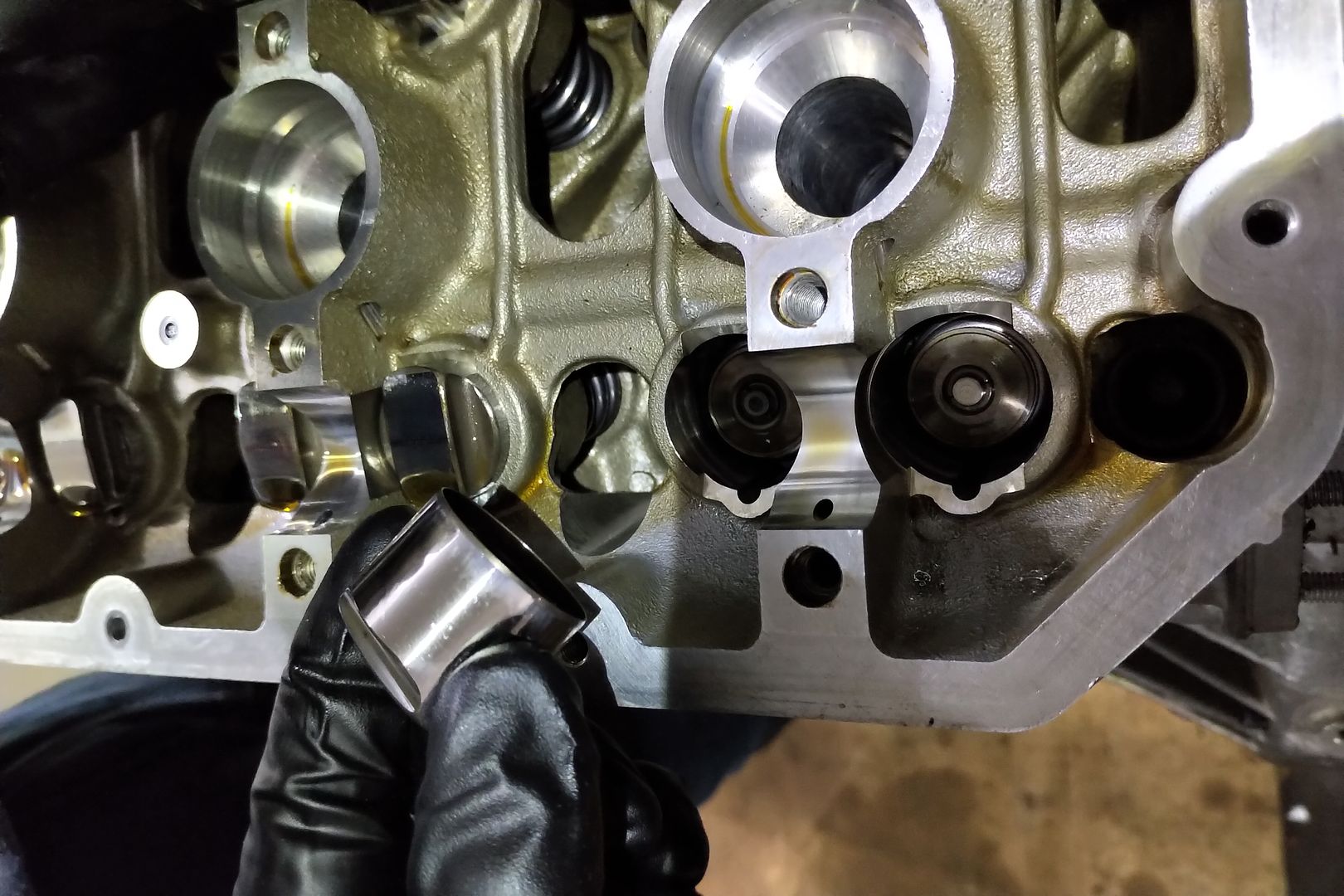

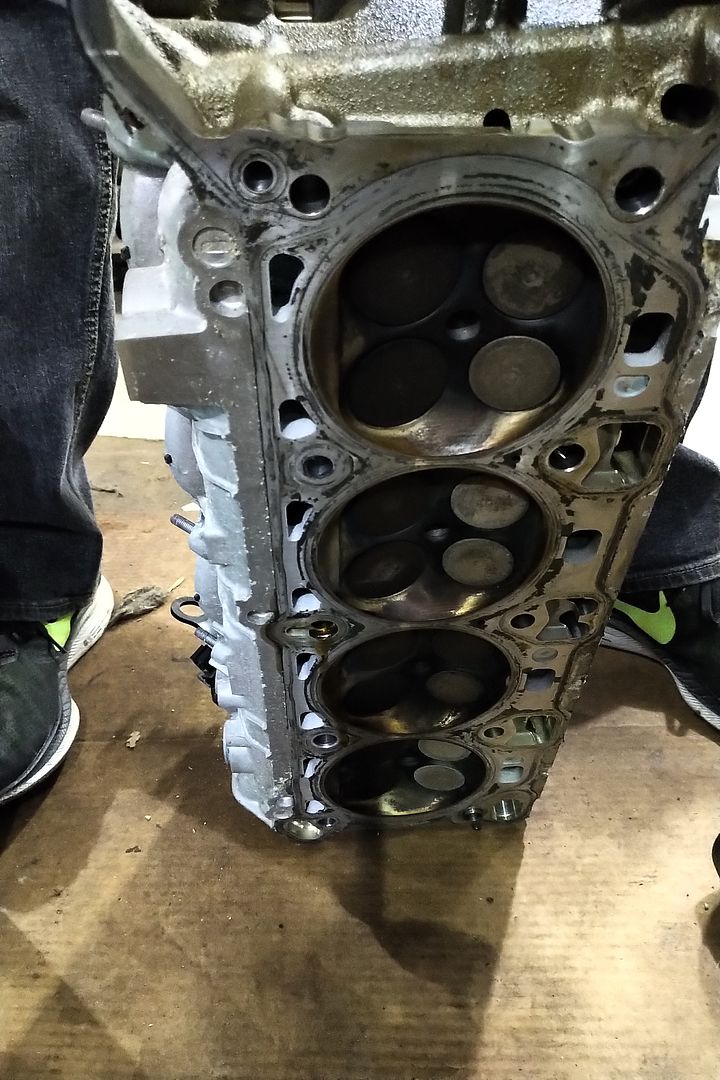

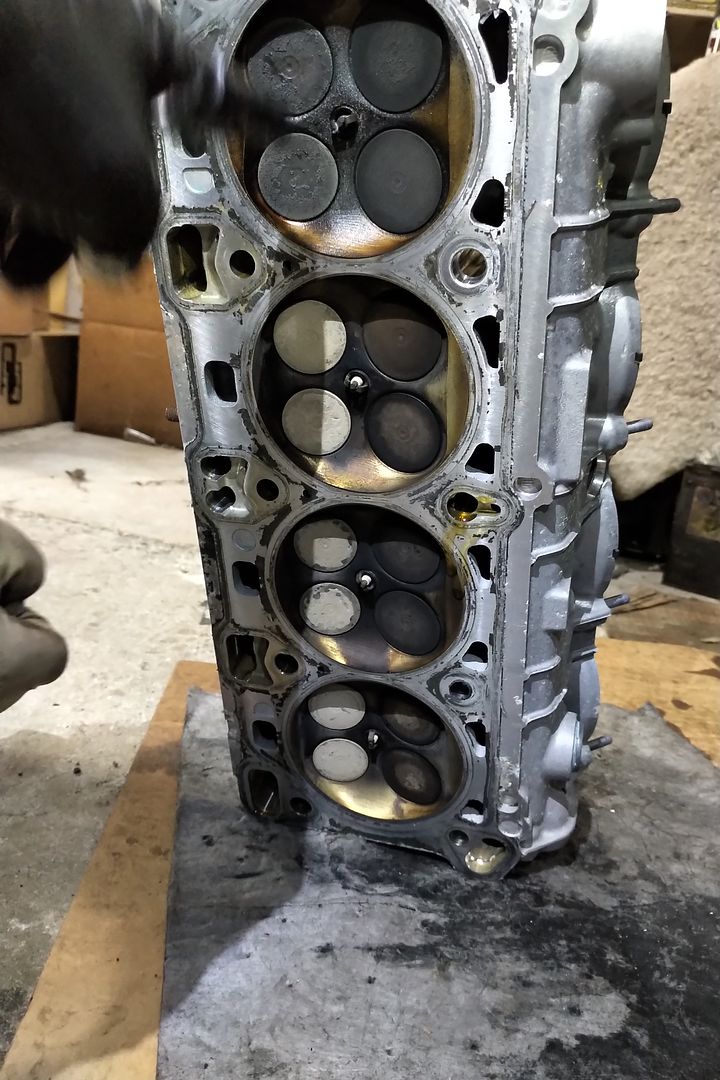

Head

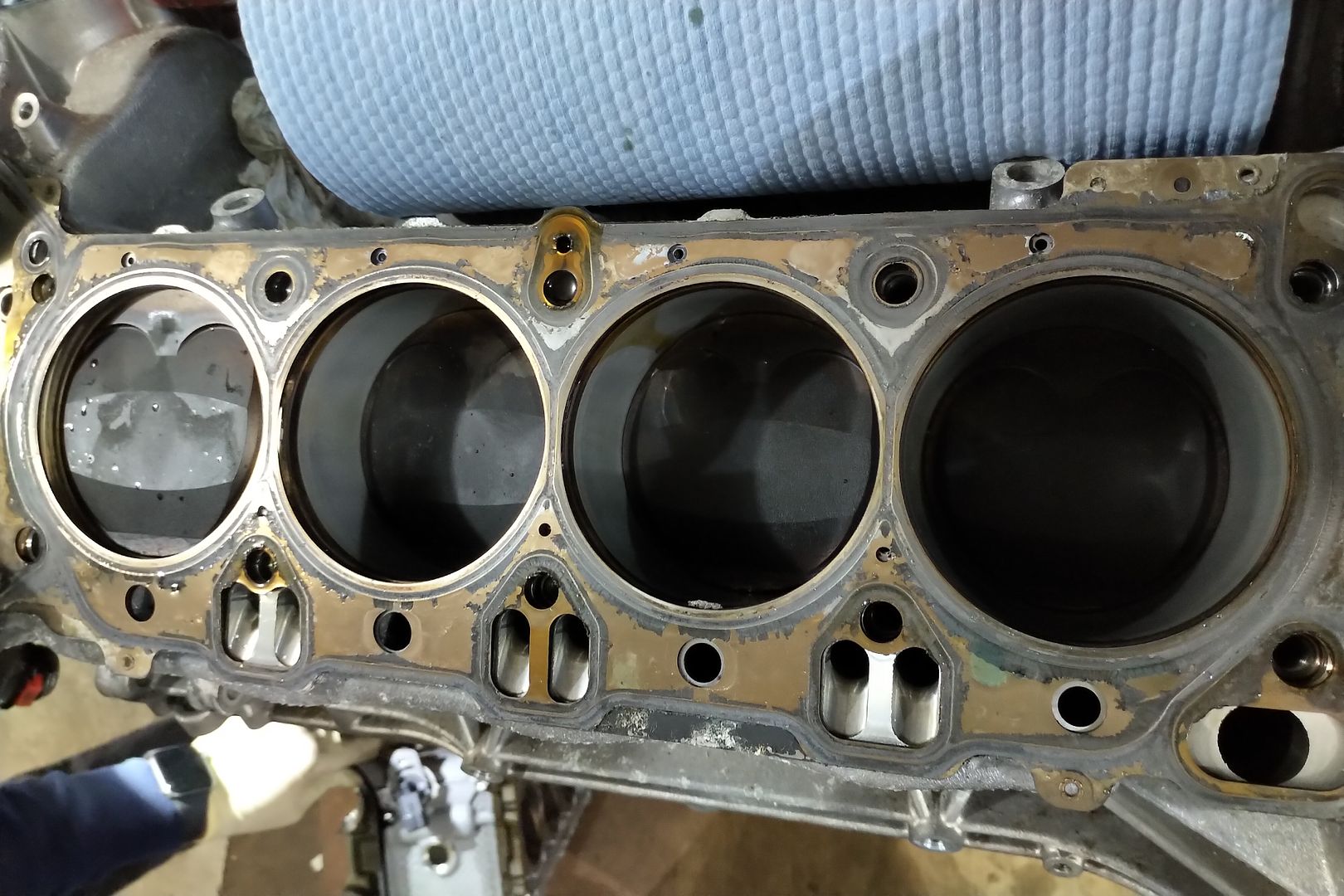

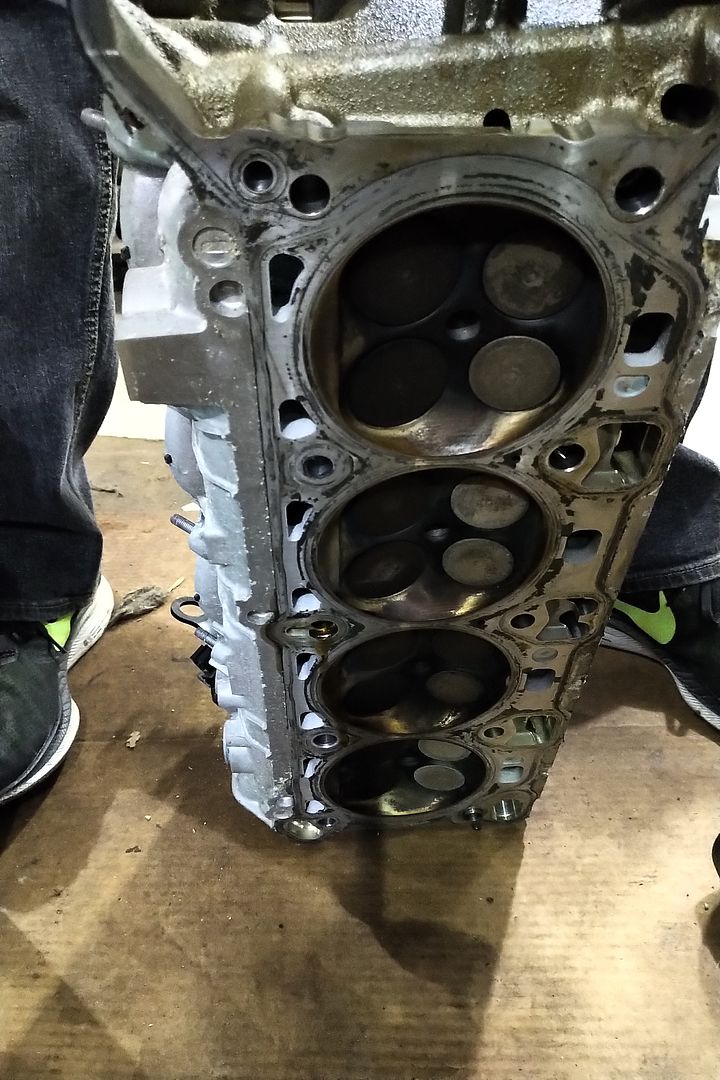

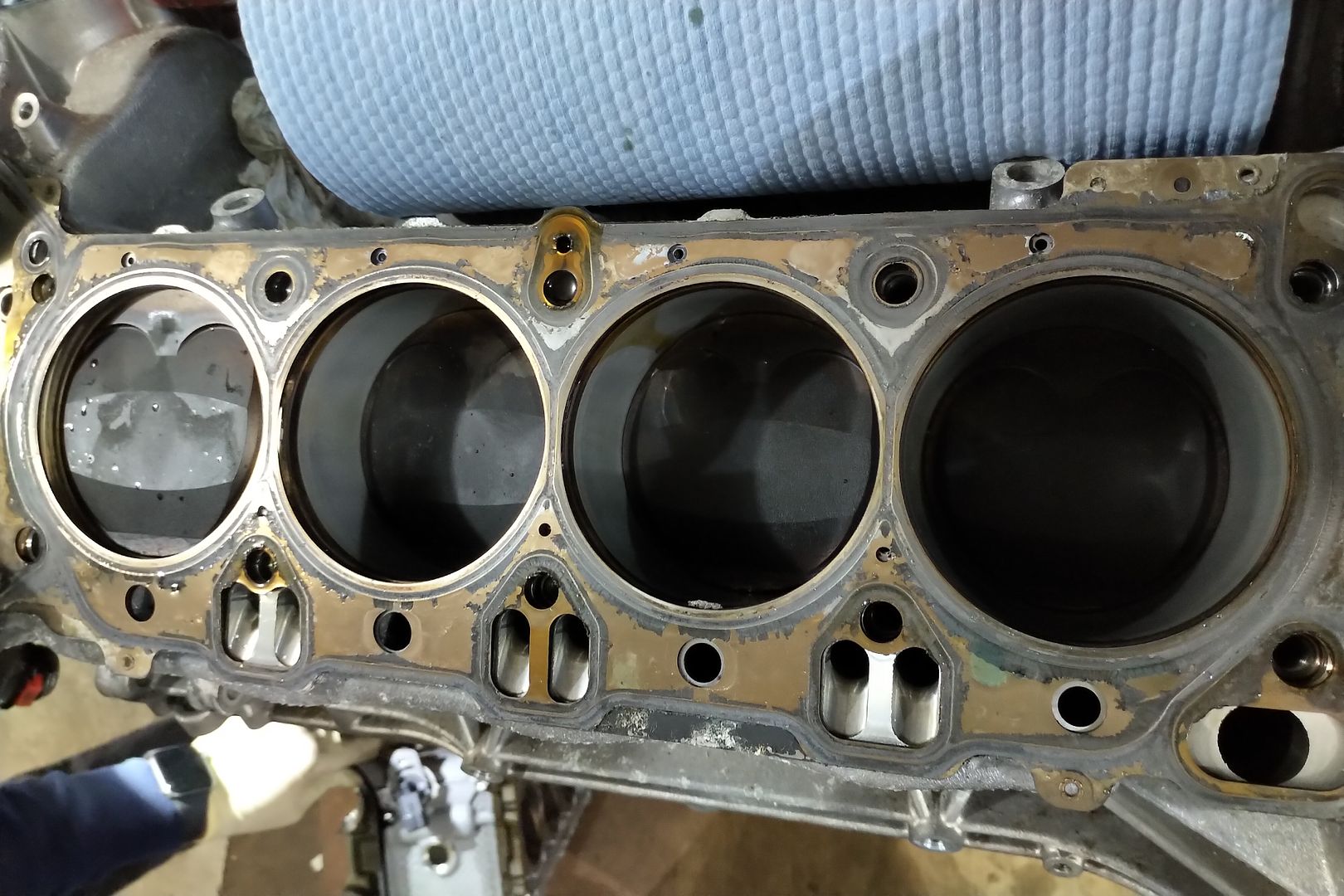

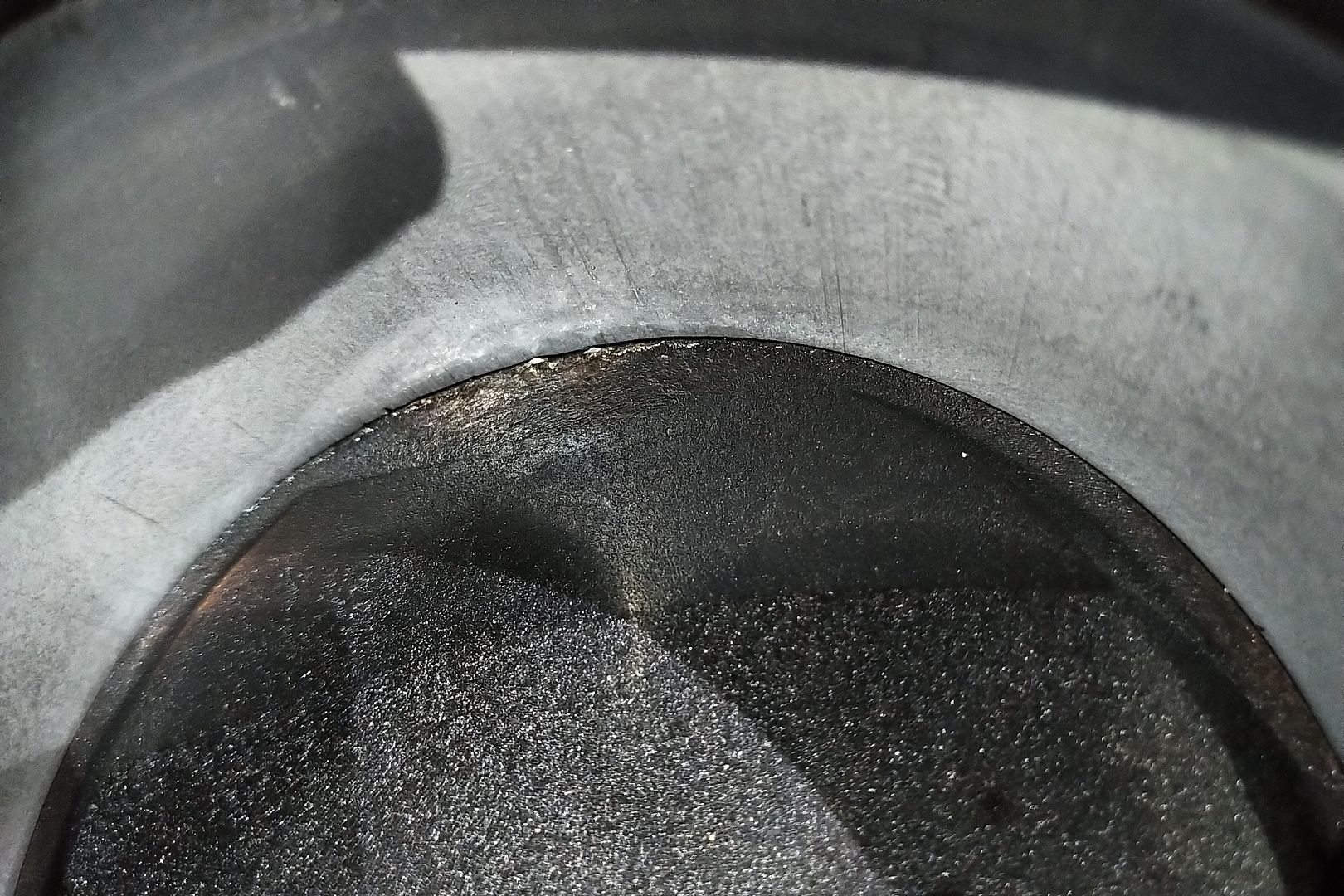

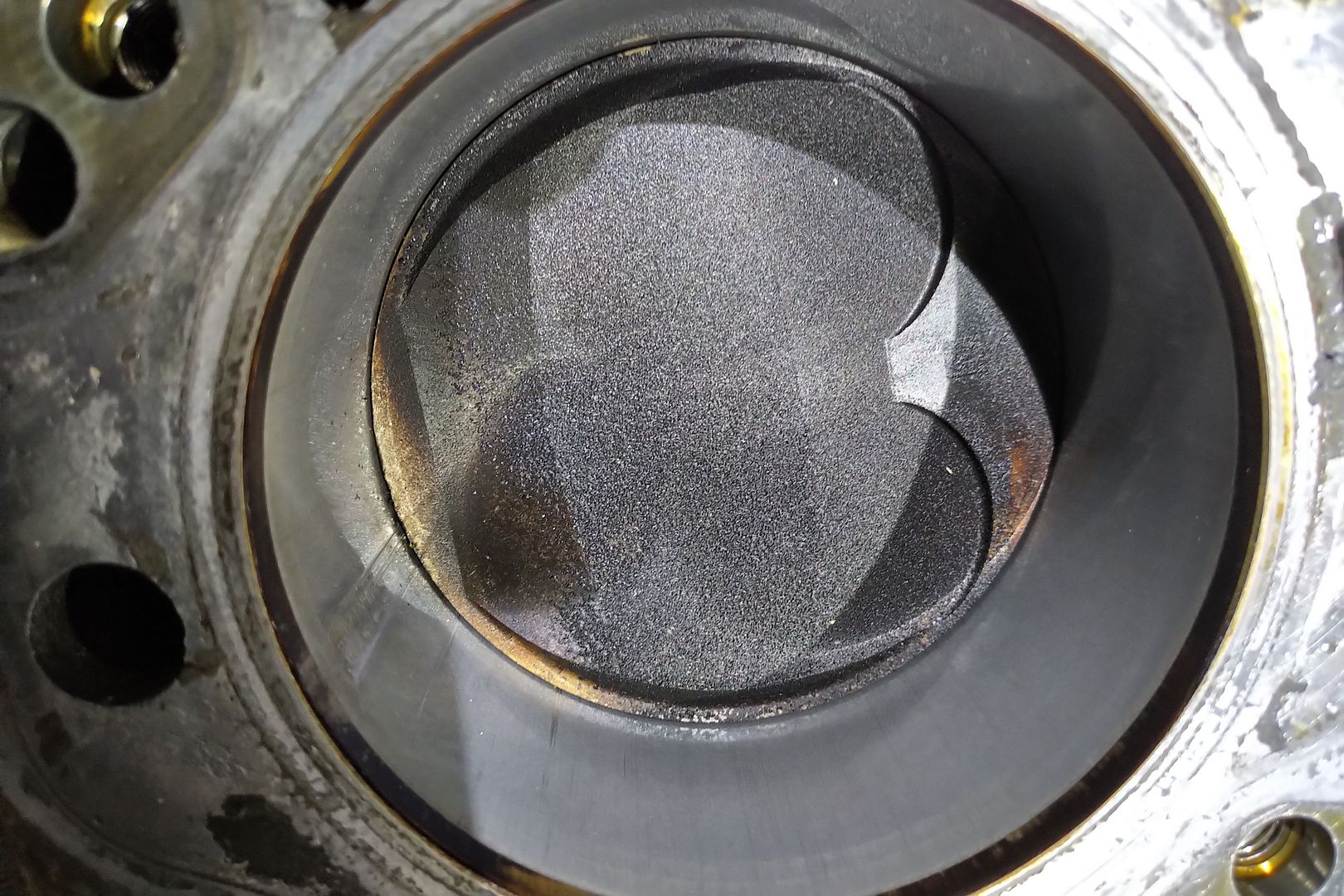

detonation

removing the cams

notice how different the first cylinder is than the rest on the head

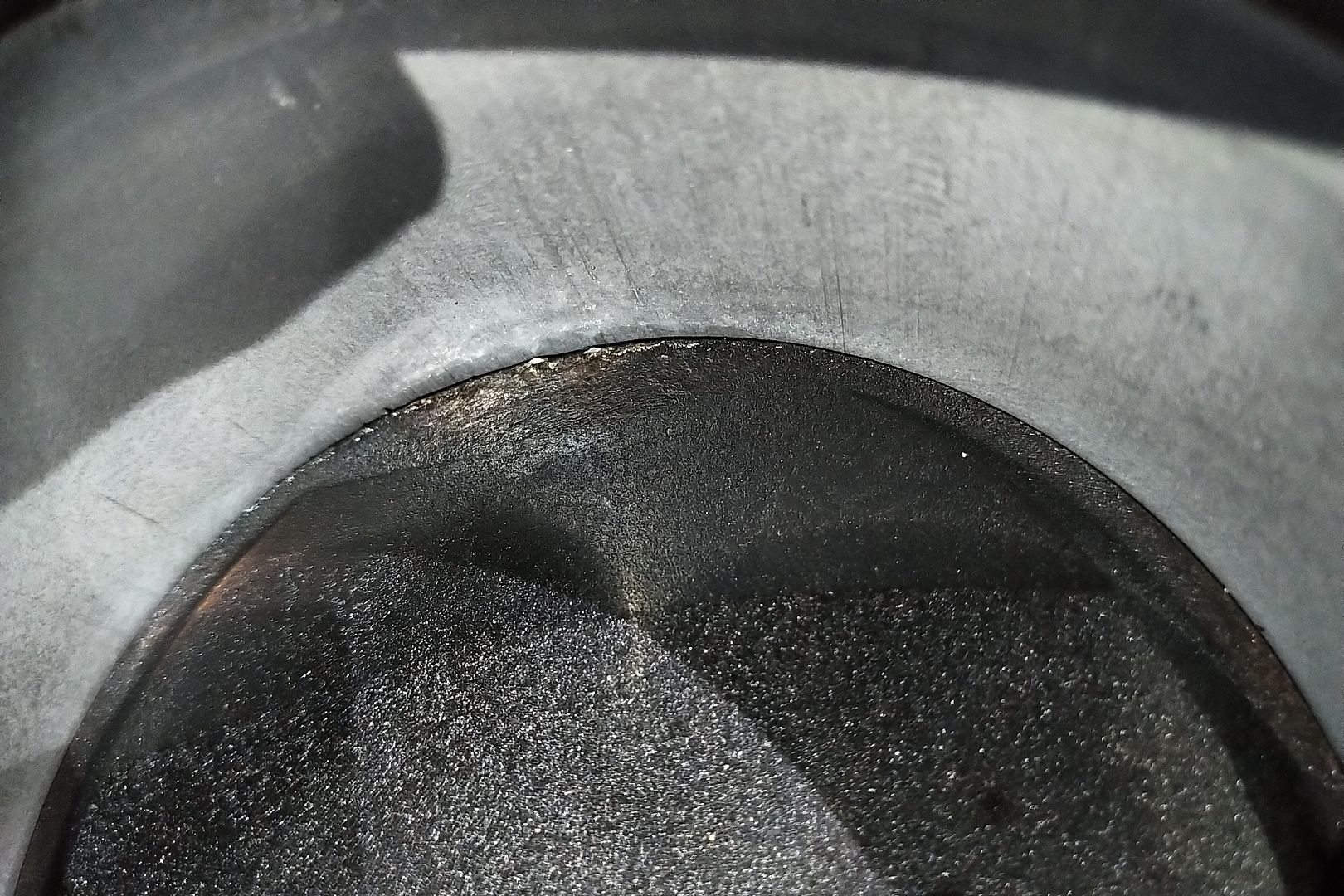

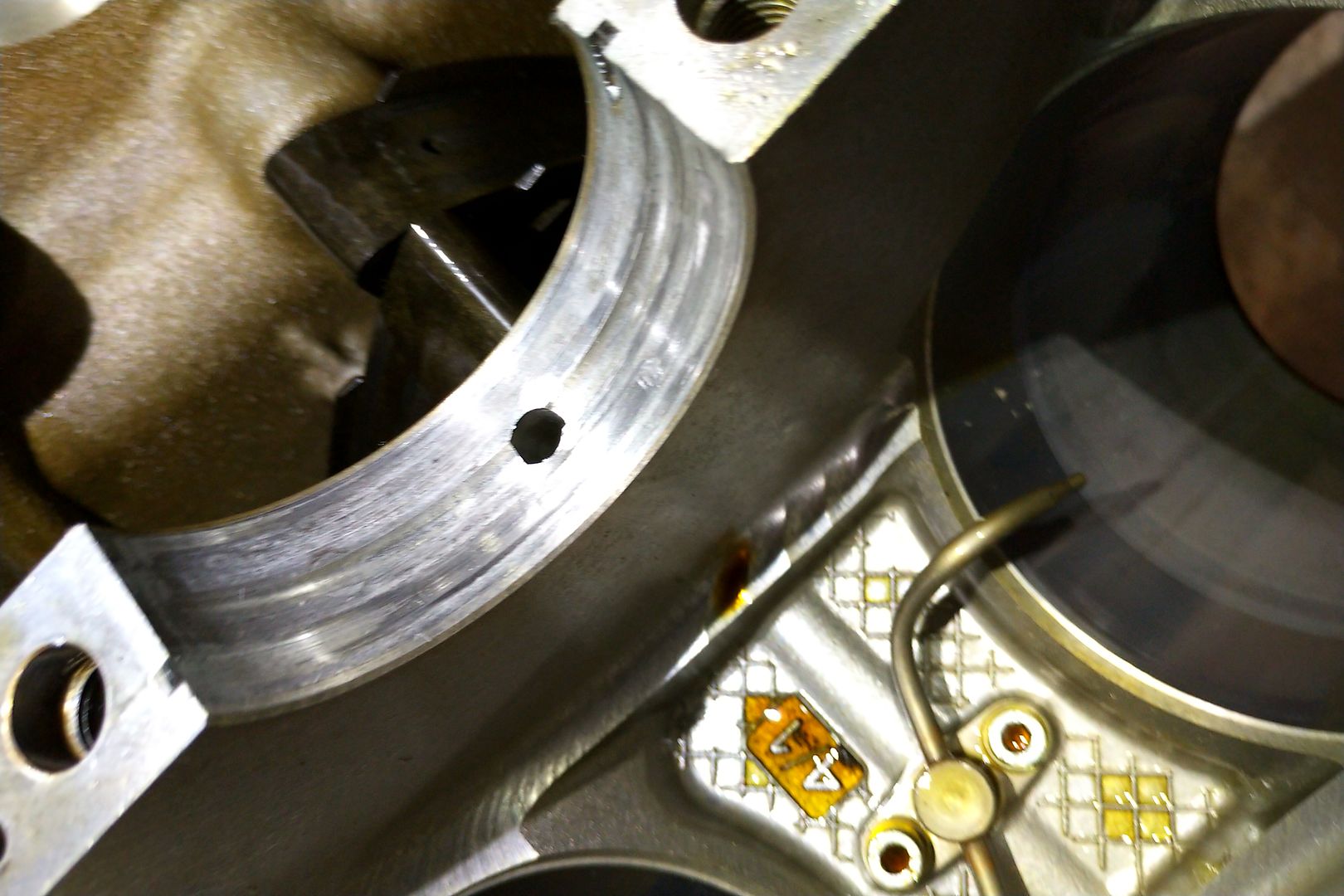

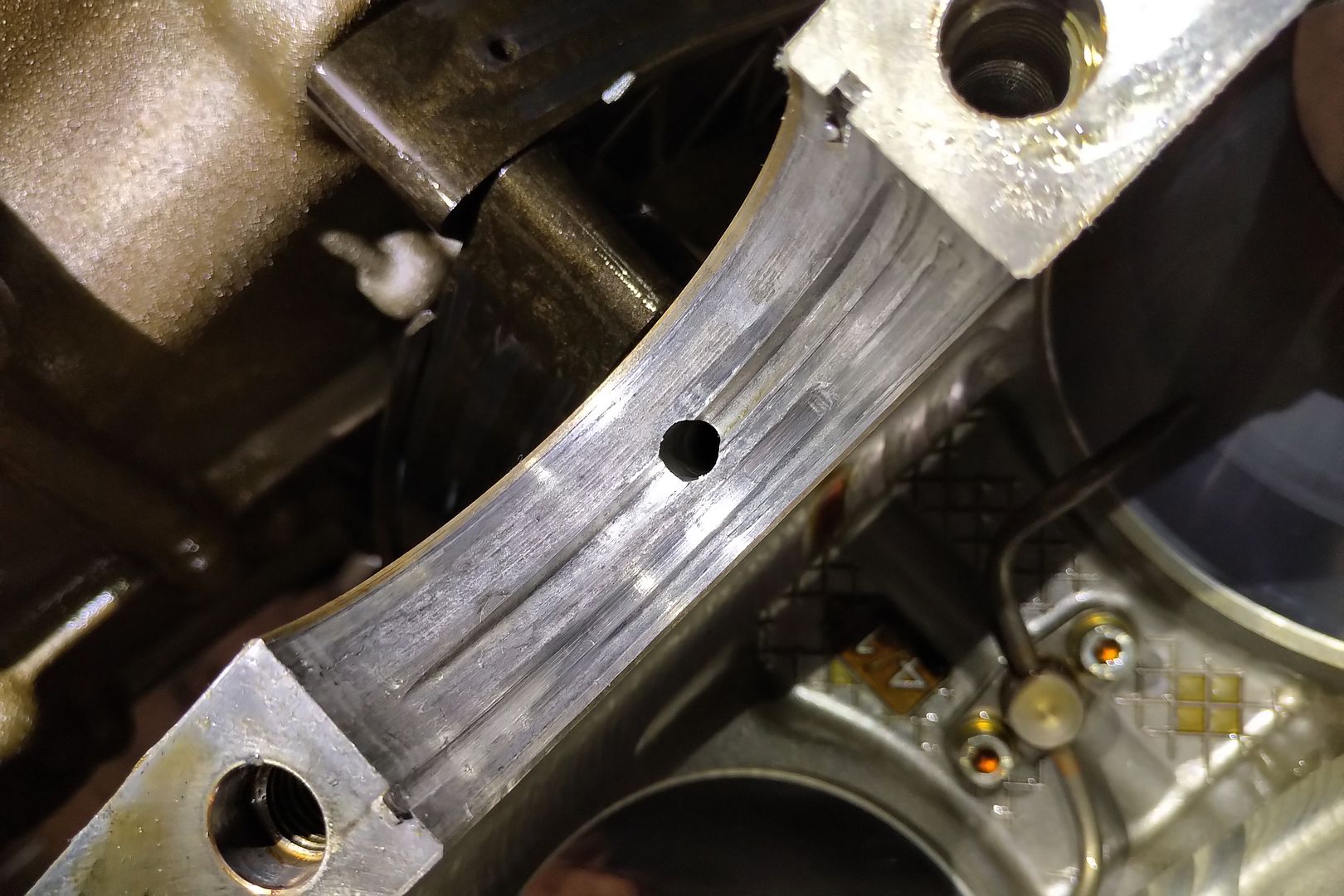

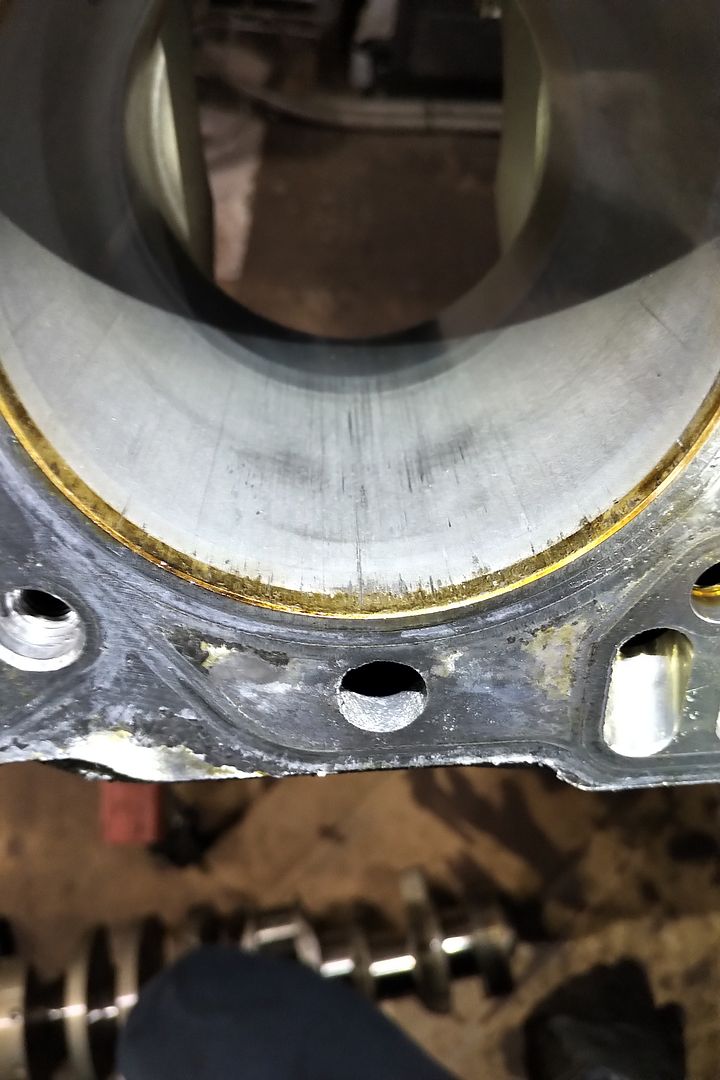

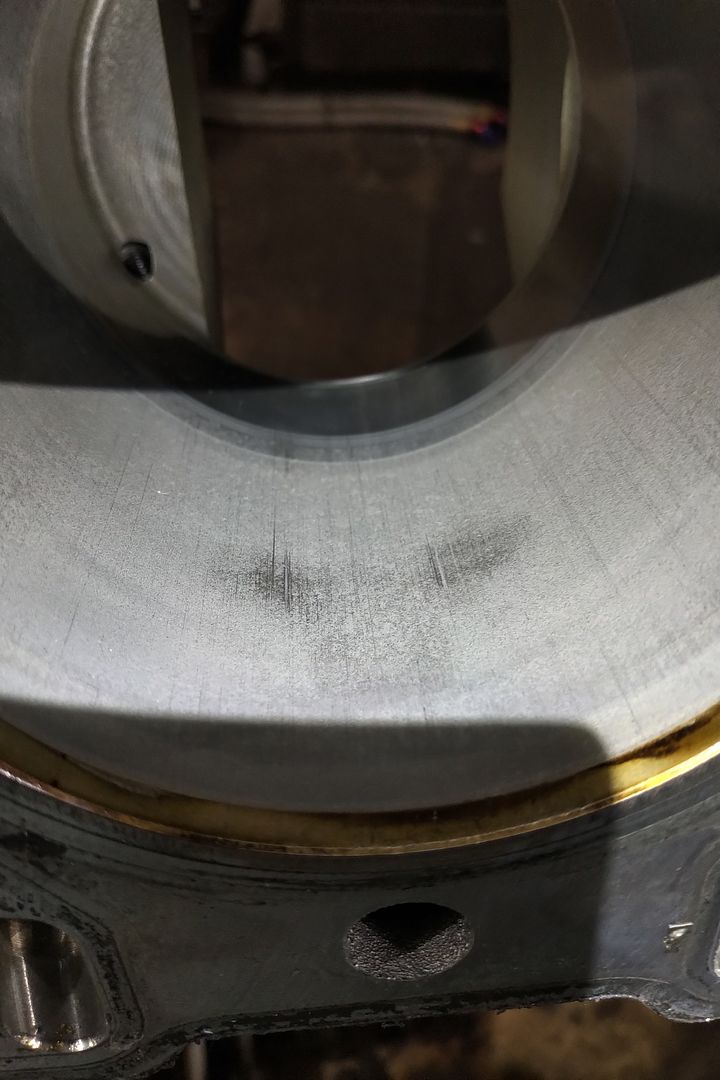

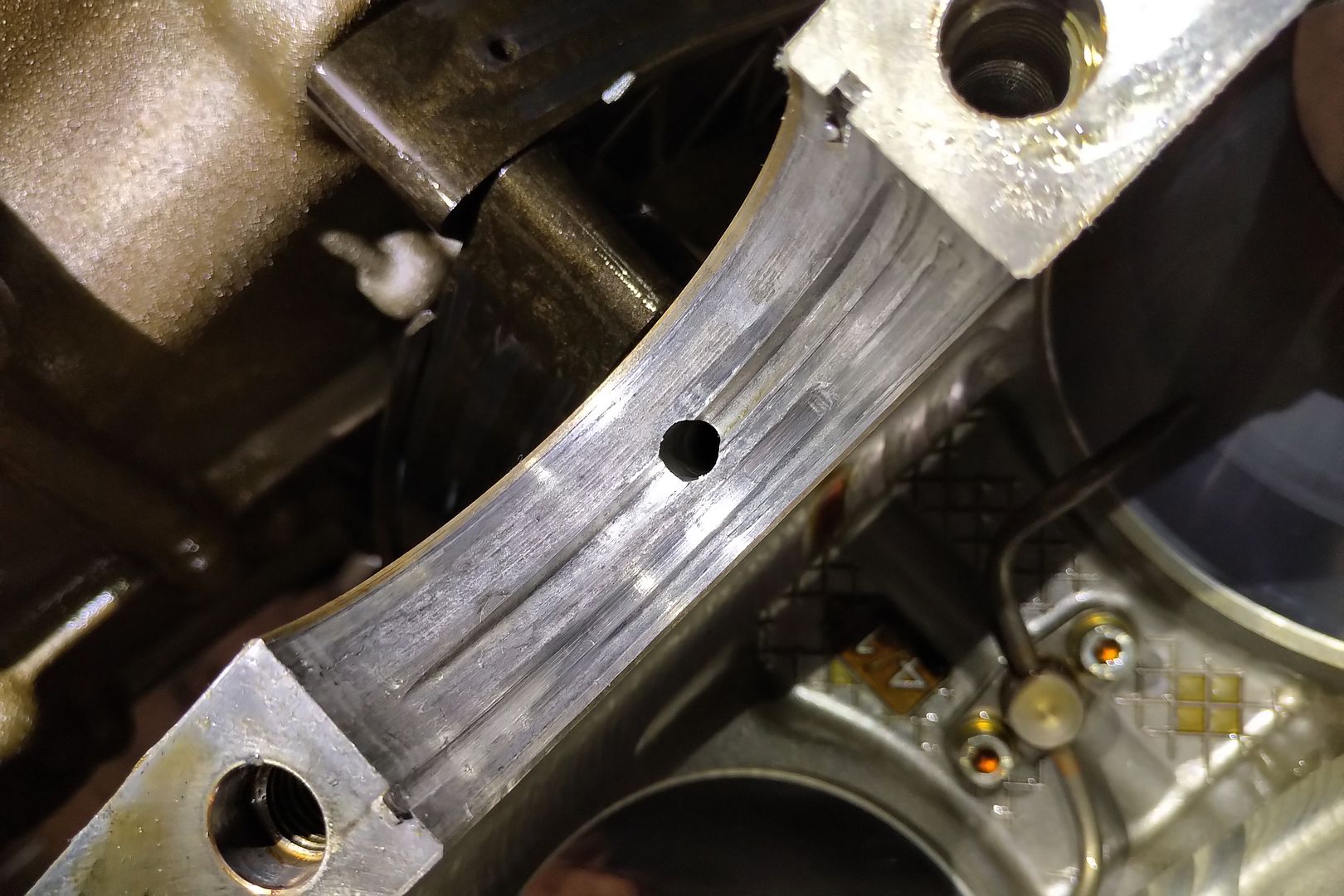

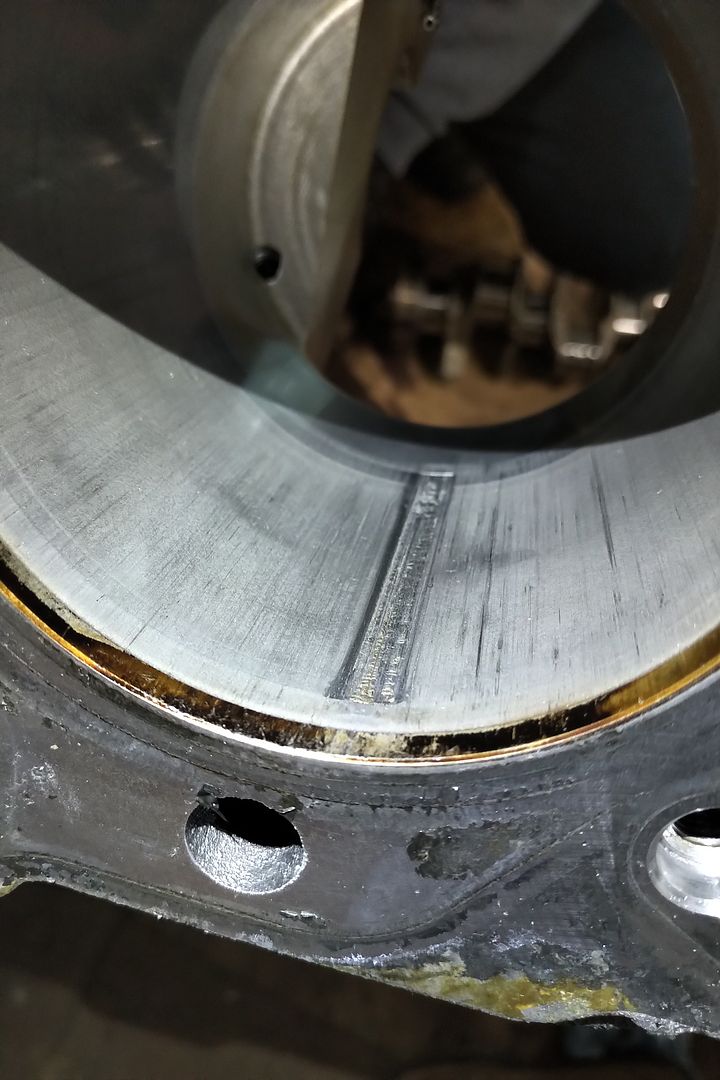

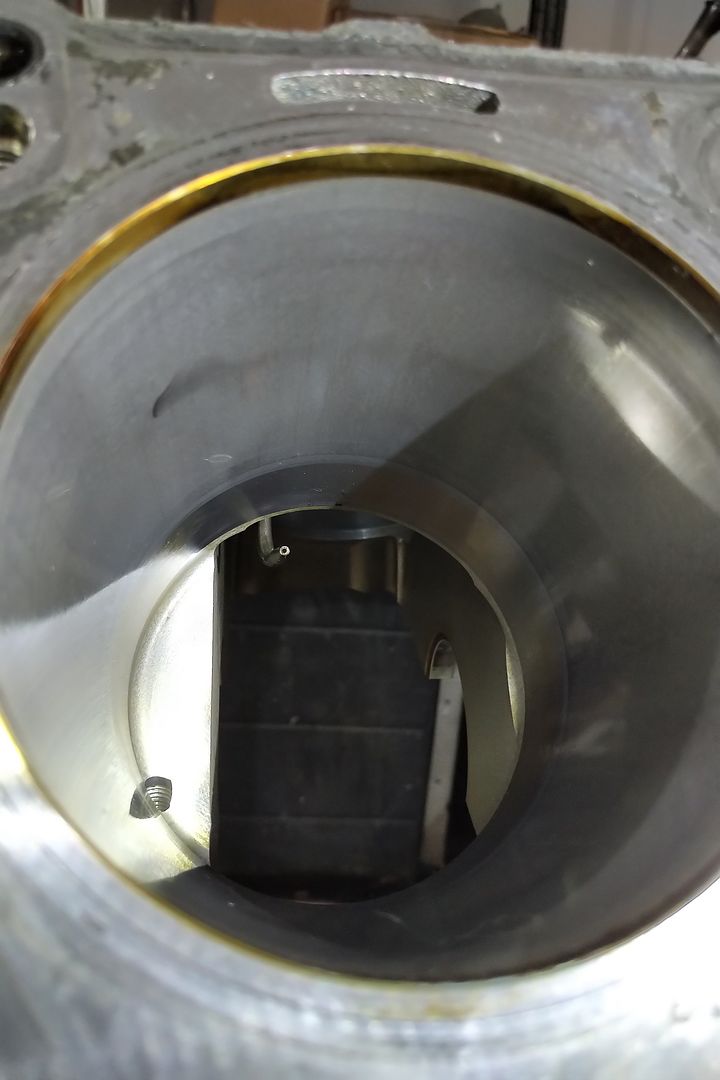

Massive scratch on the cylinder wall

More detonation

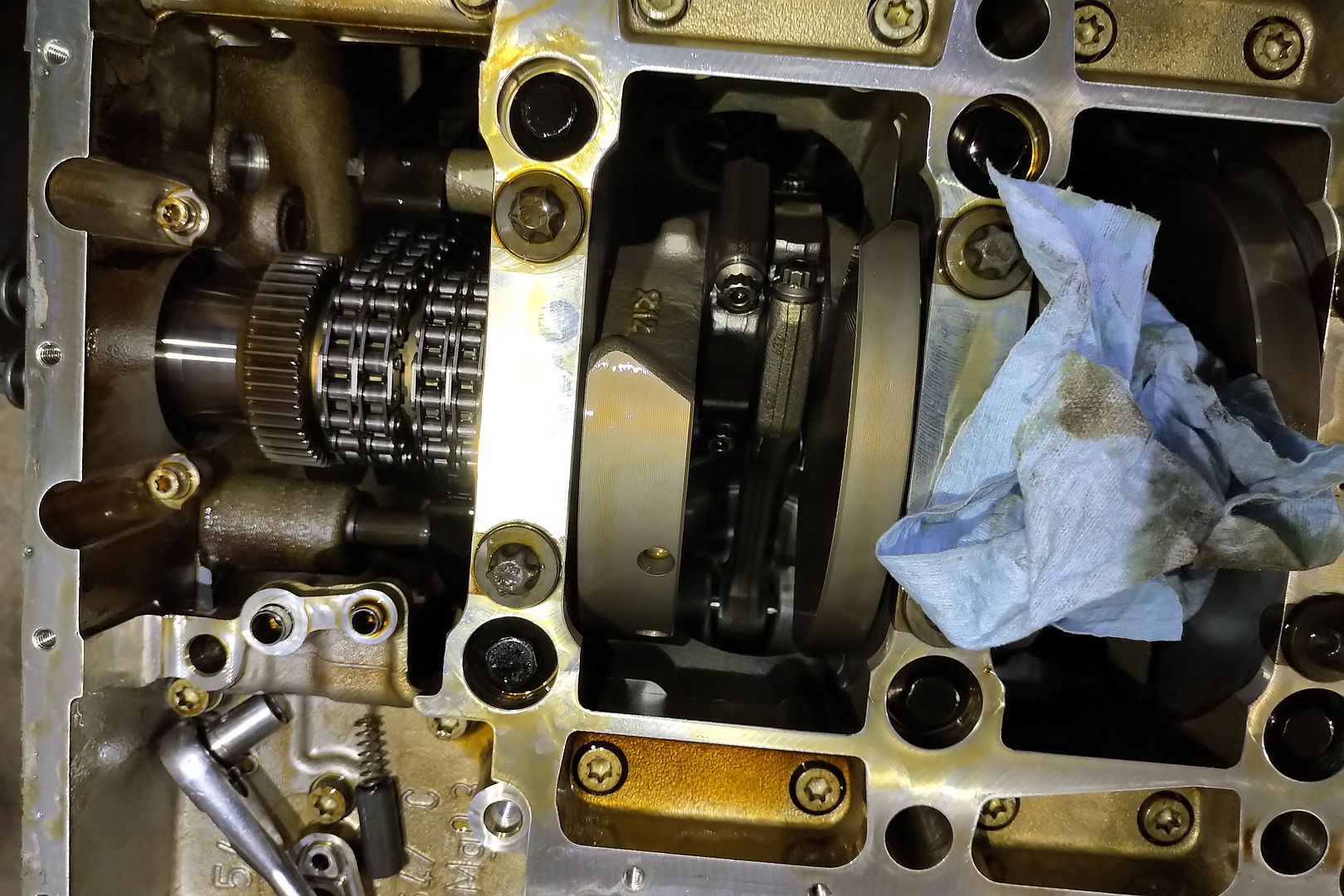

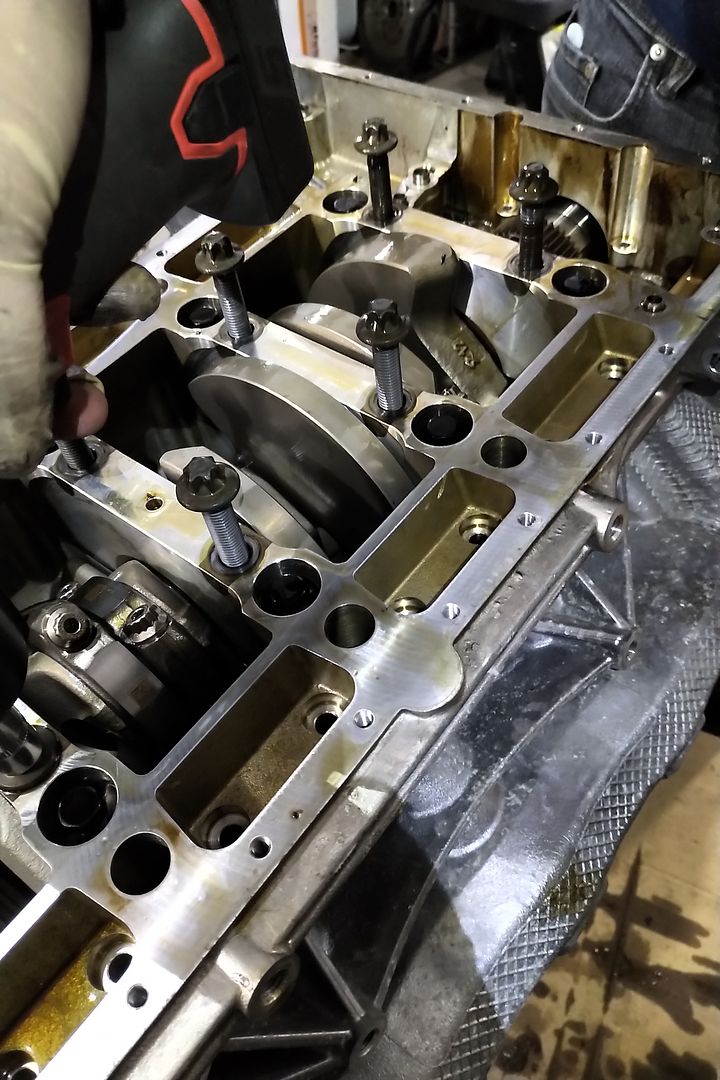

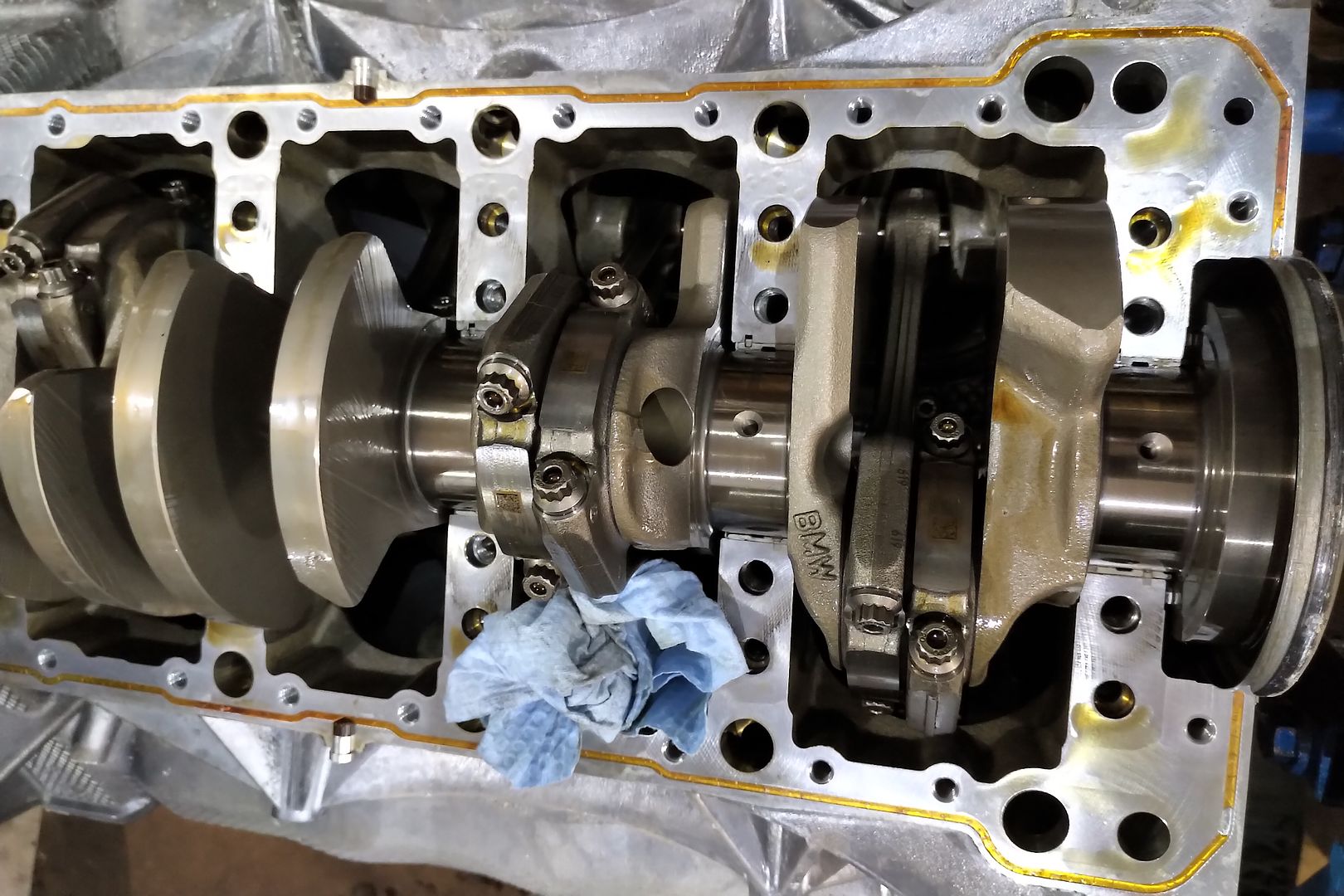

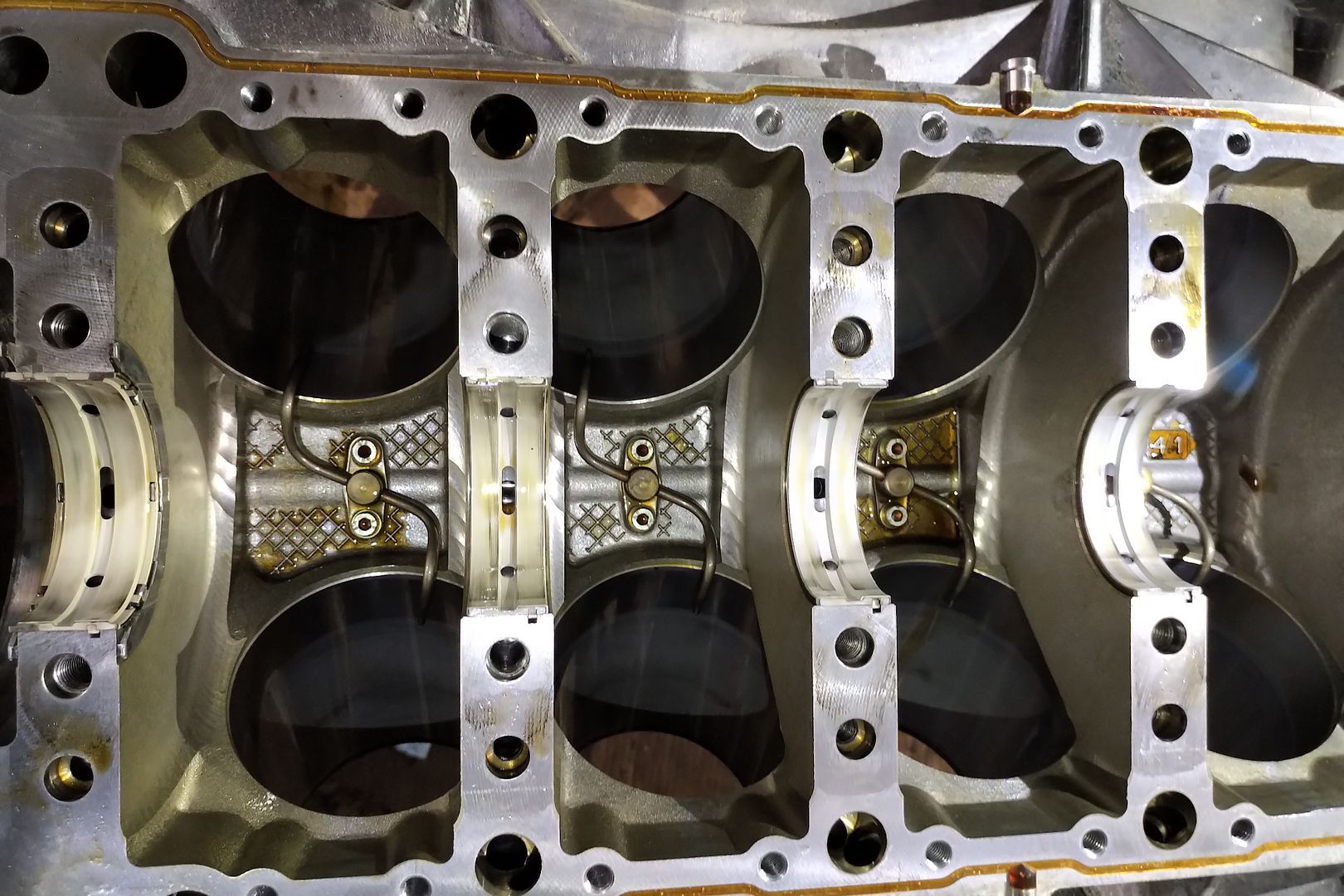

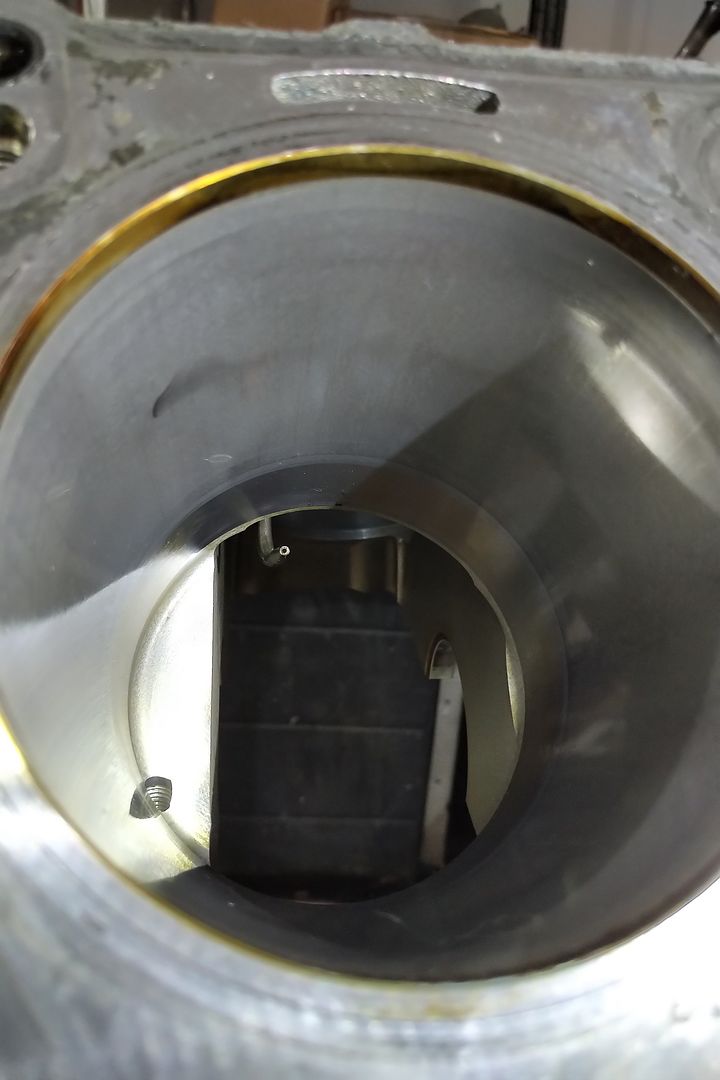

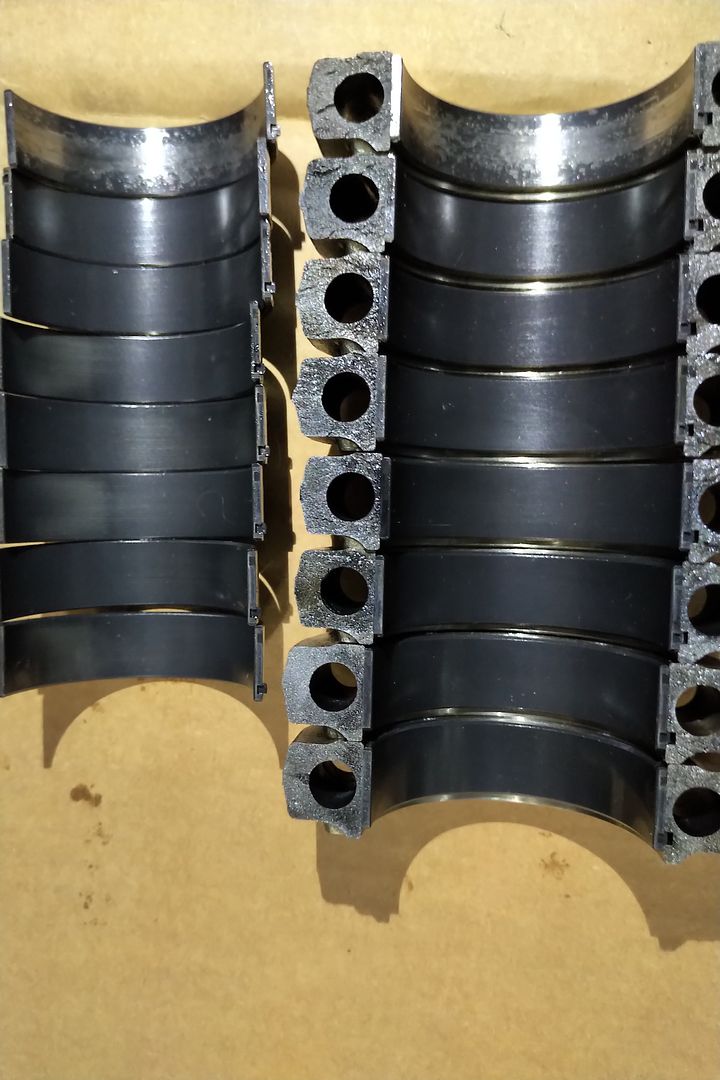

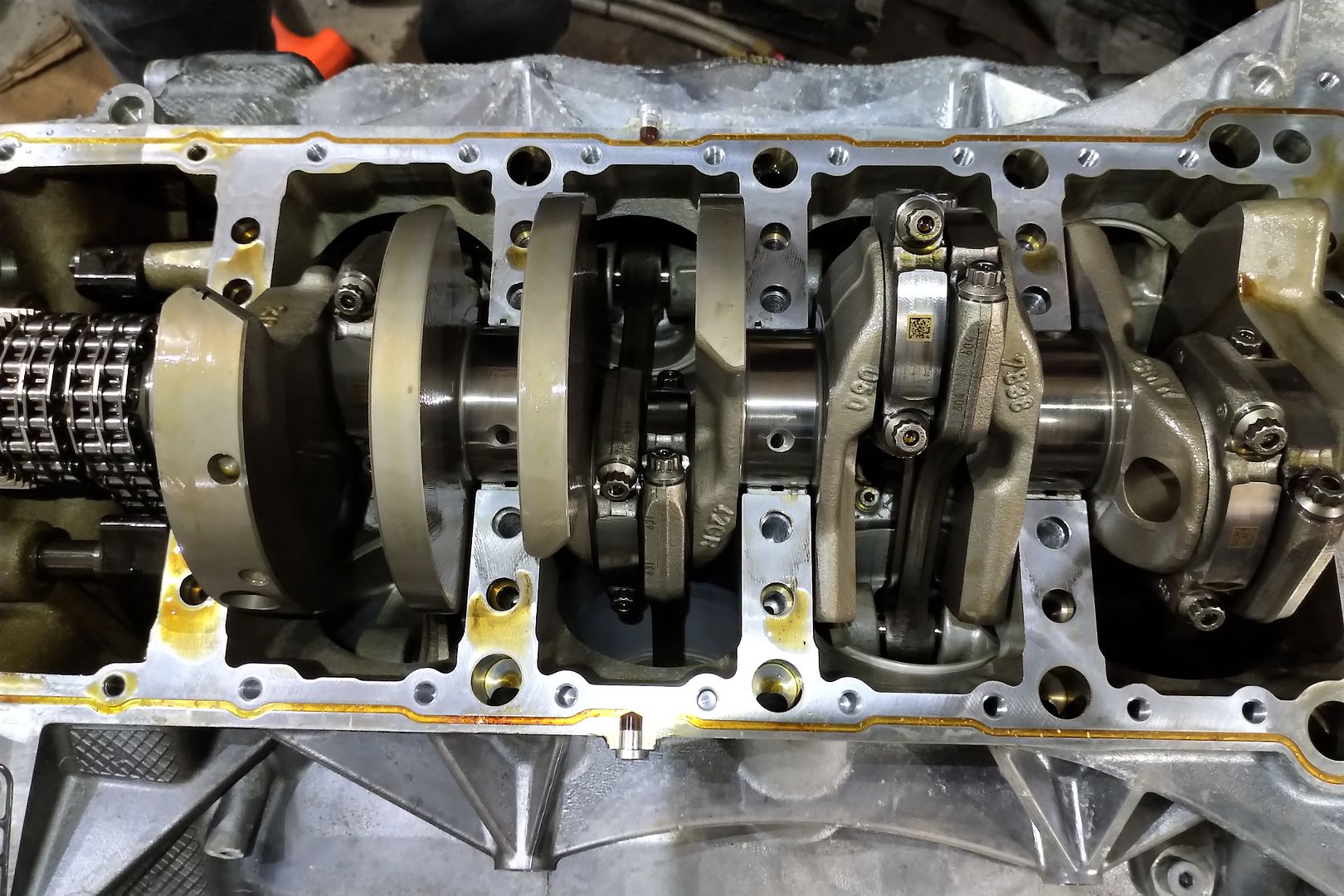

this is what you see in any rod bearing job

you can see the be-arp bolts here

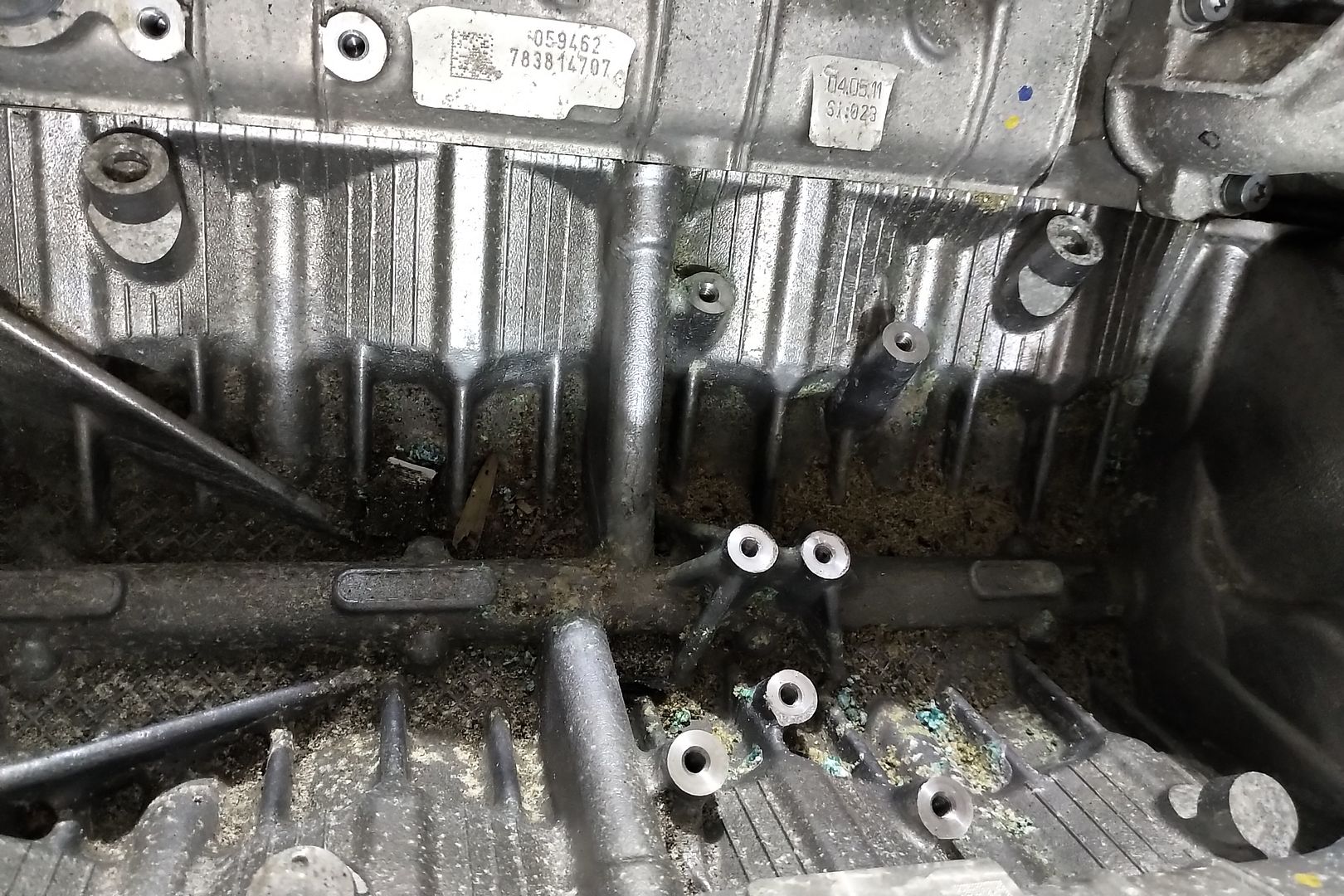

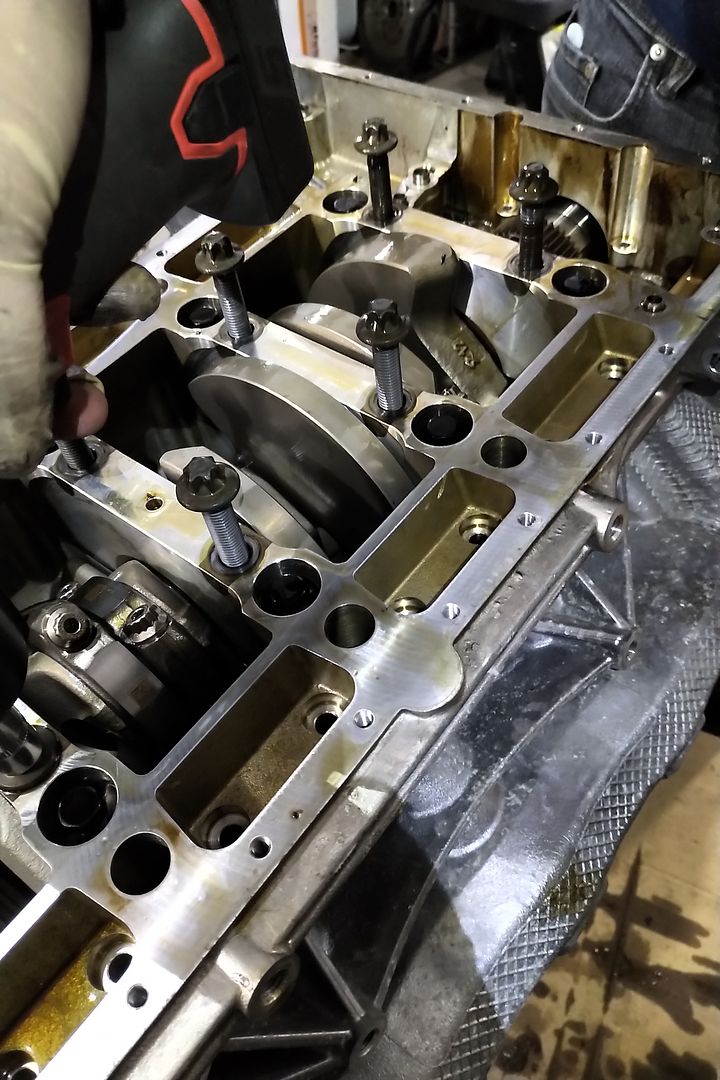

removing bedplate

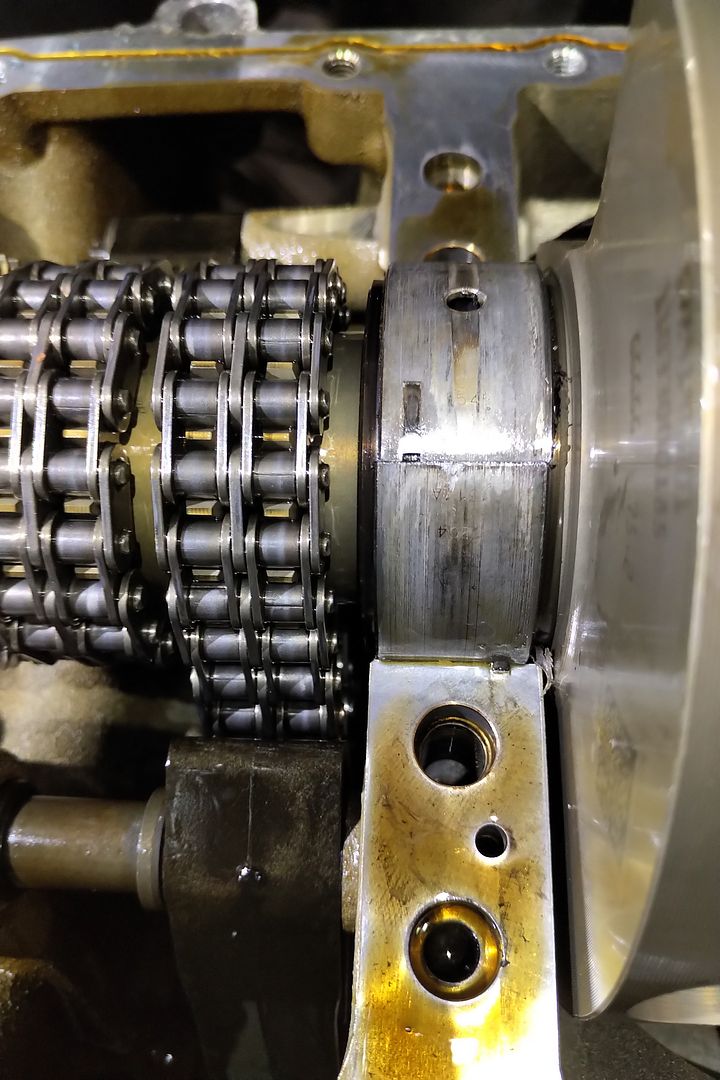

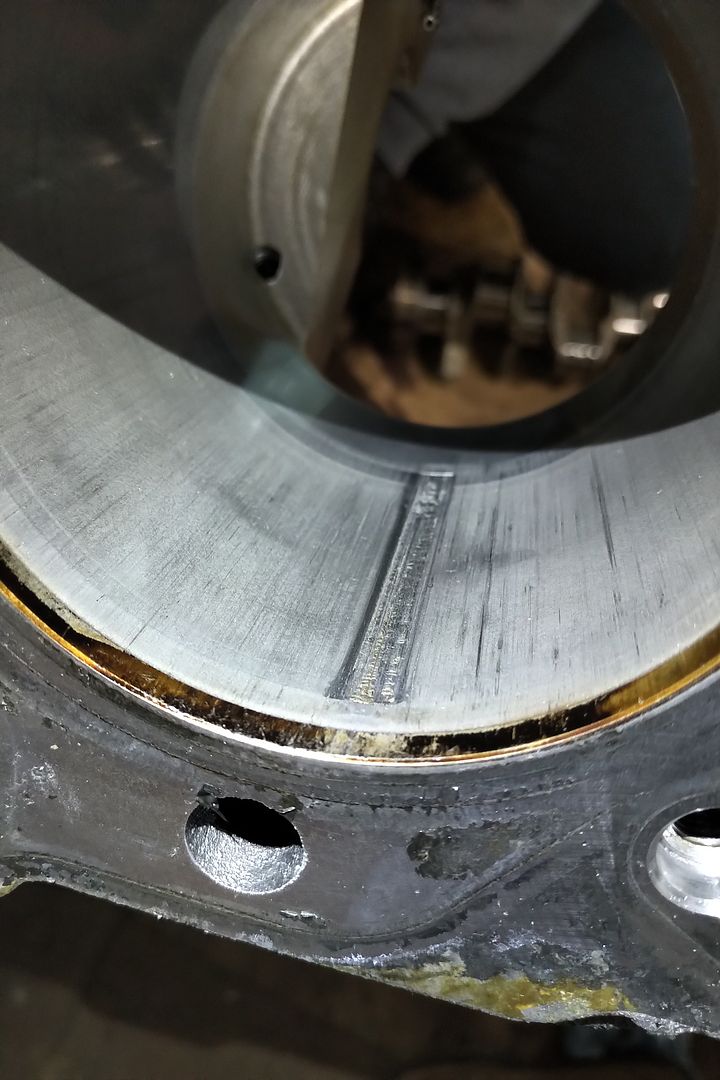

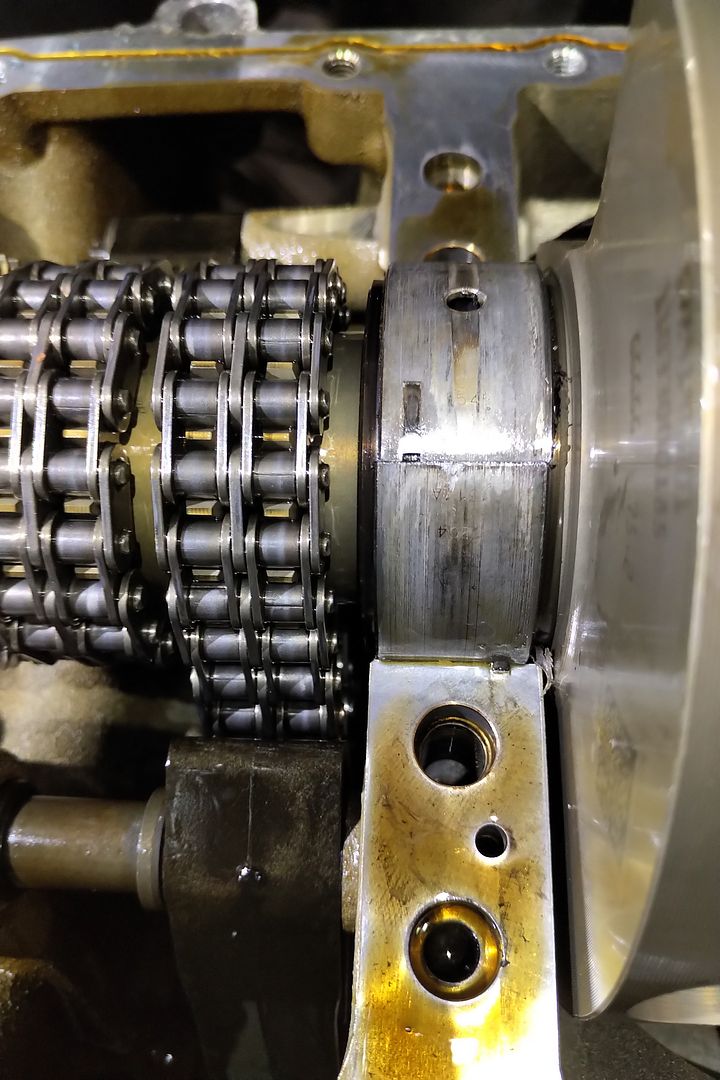

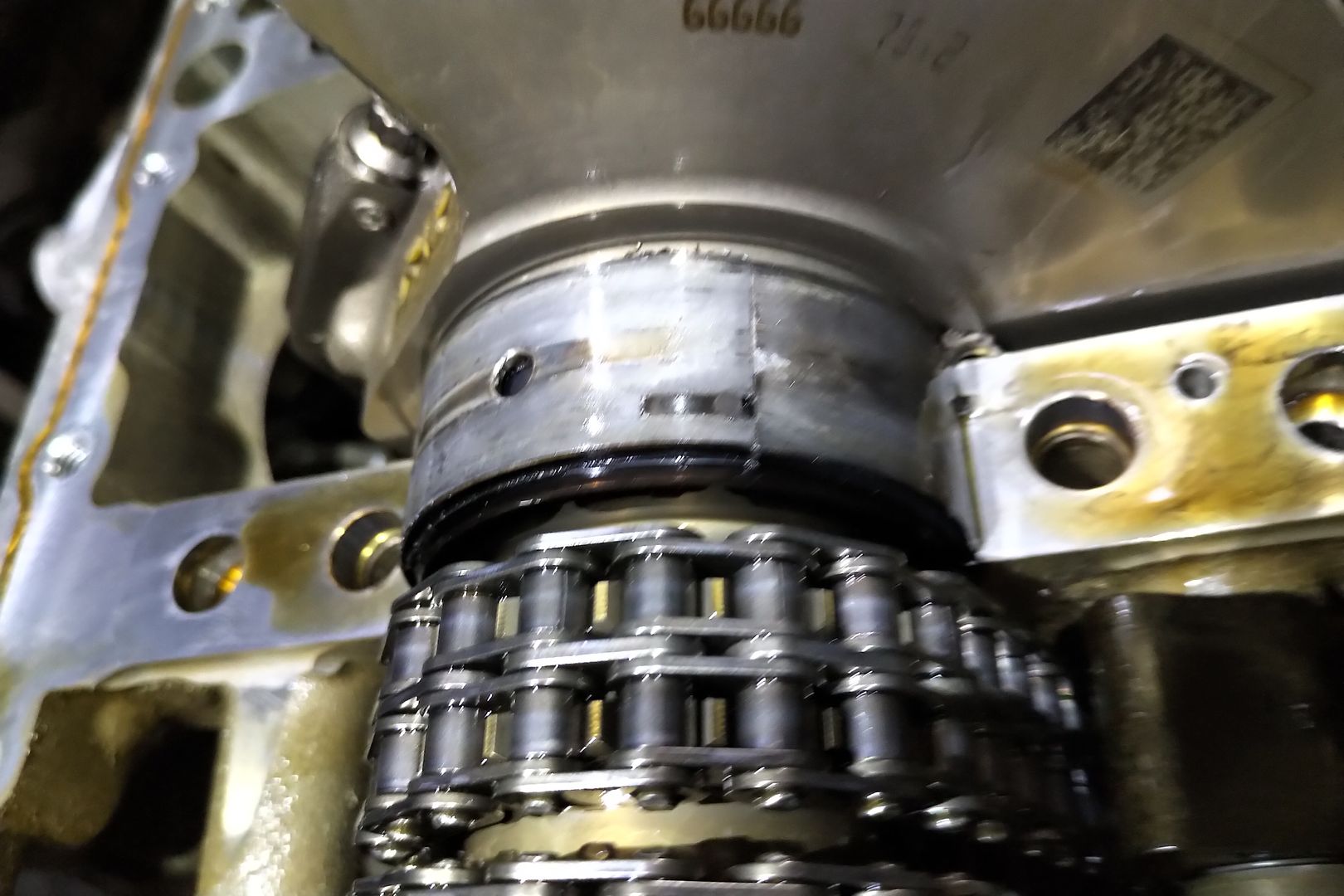

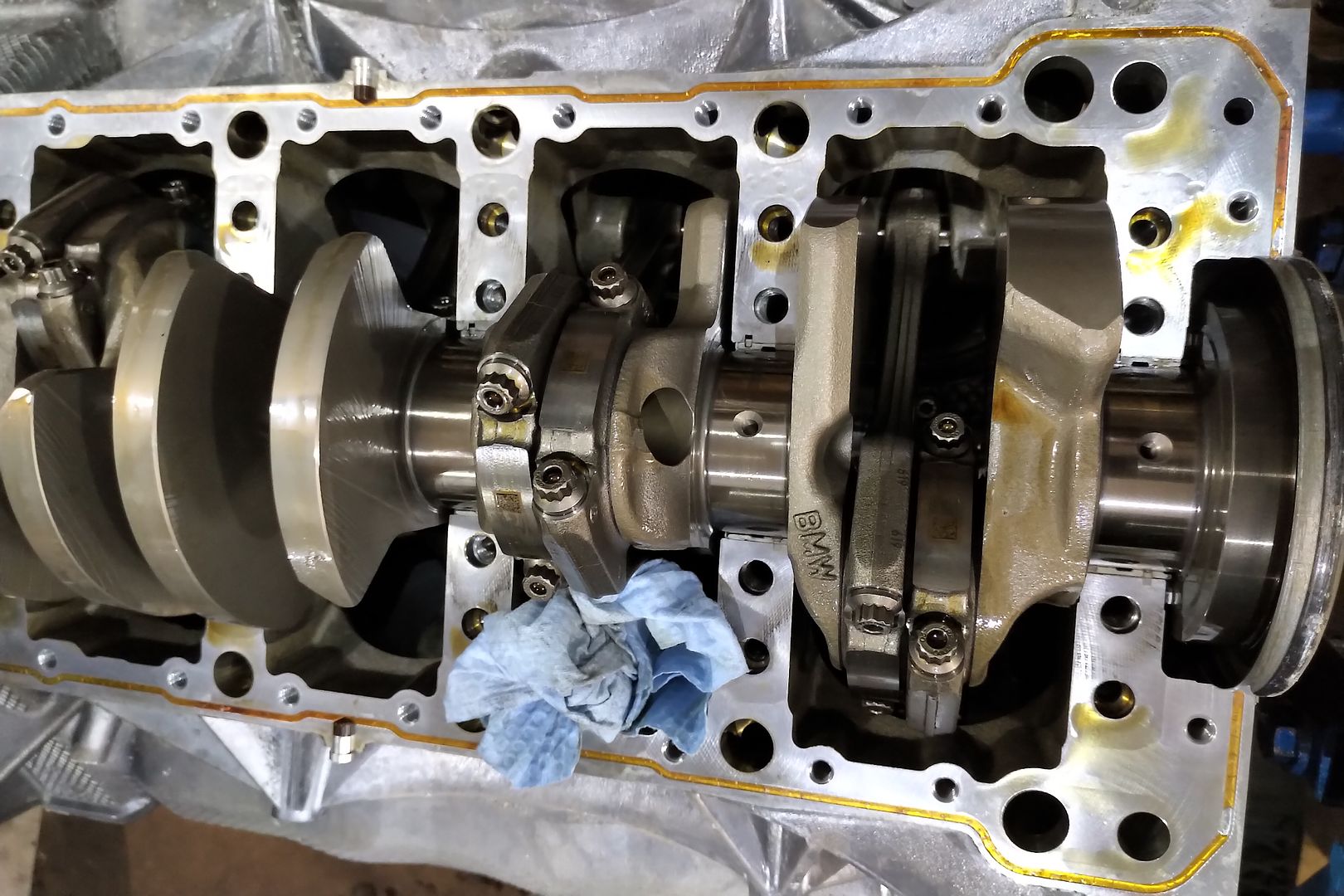

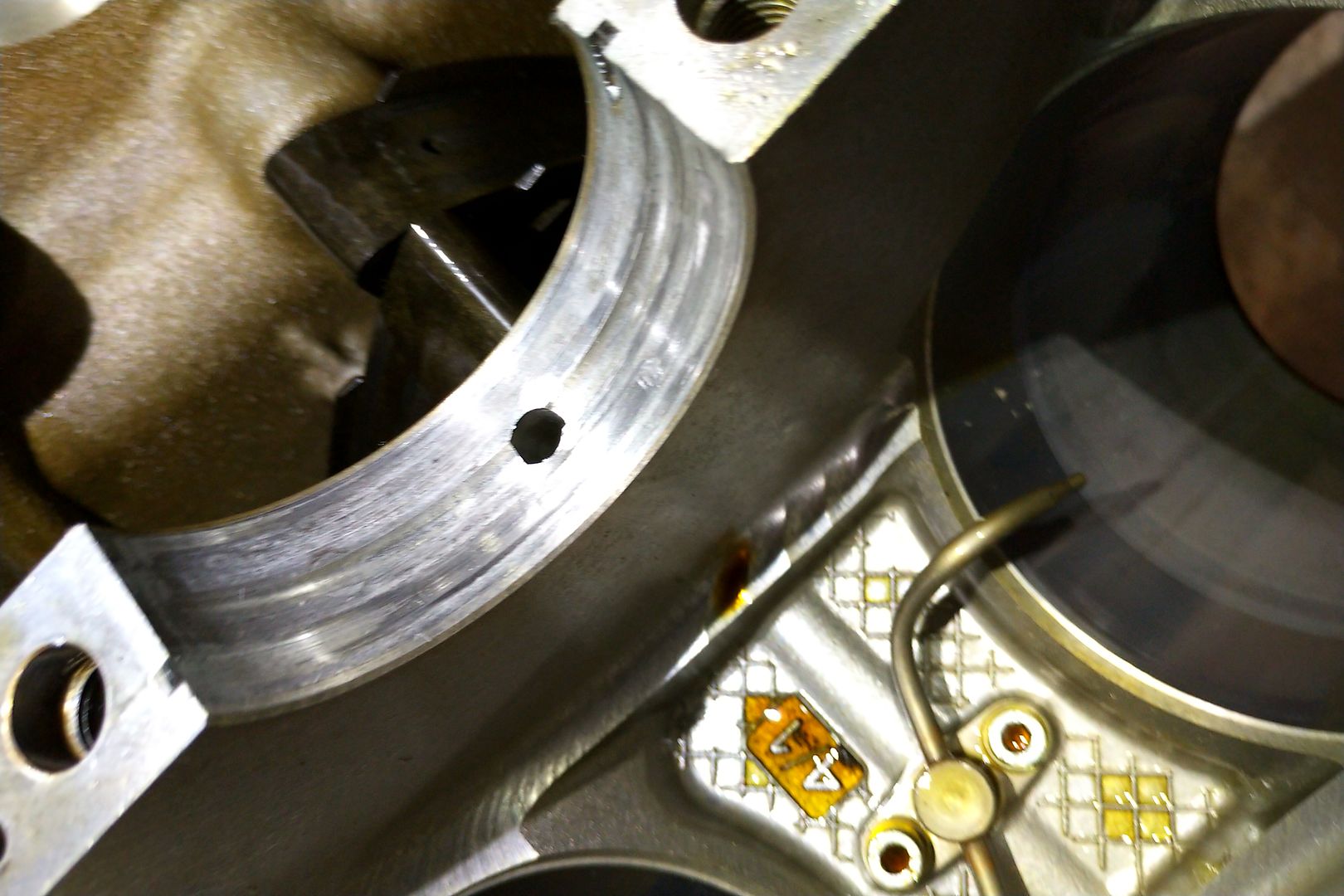

main bearing #1 spun :cry:

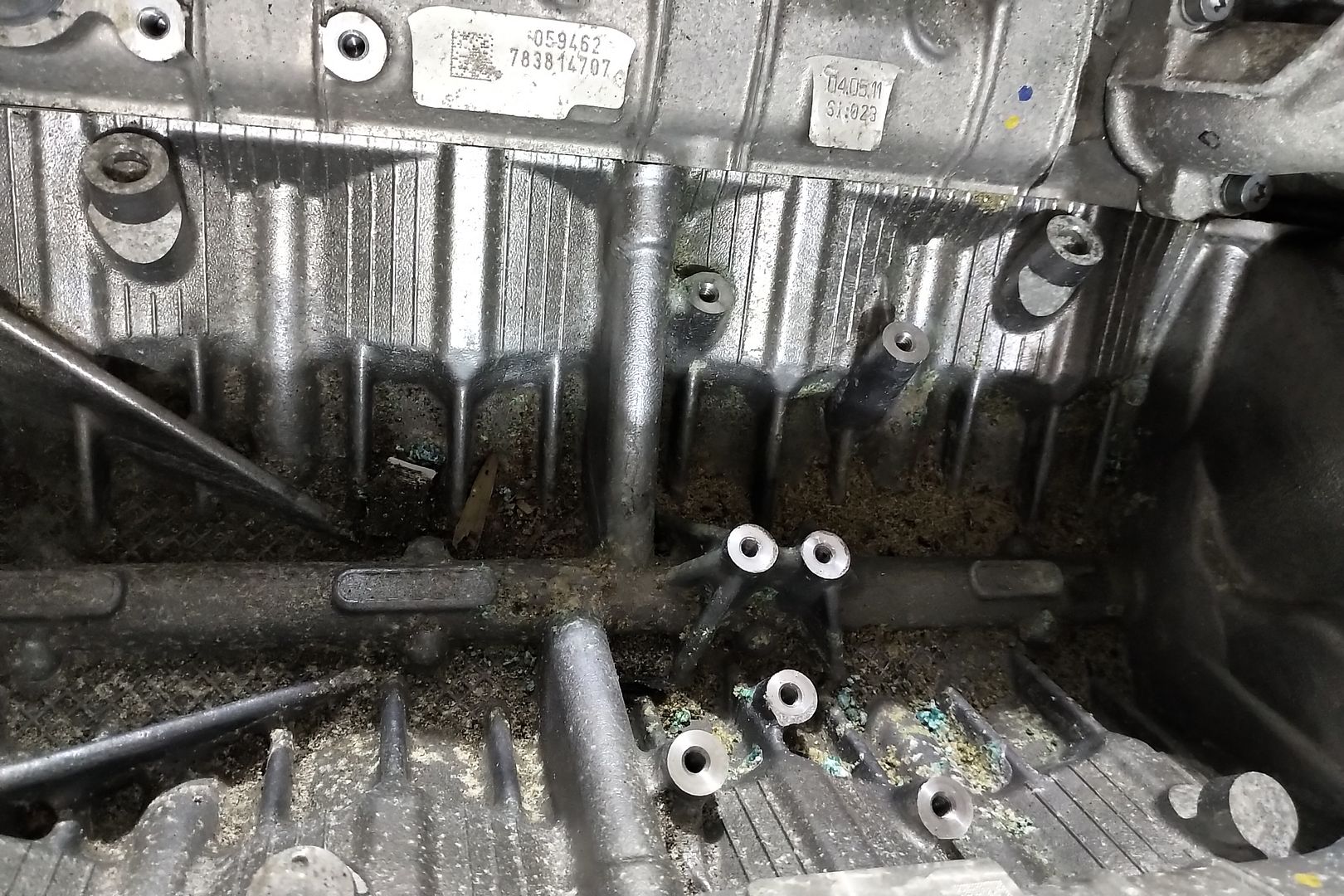

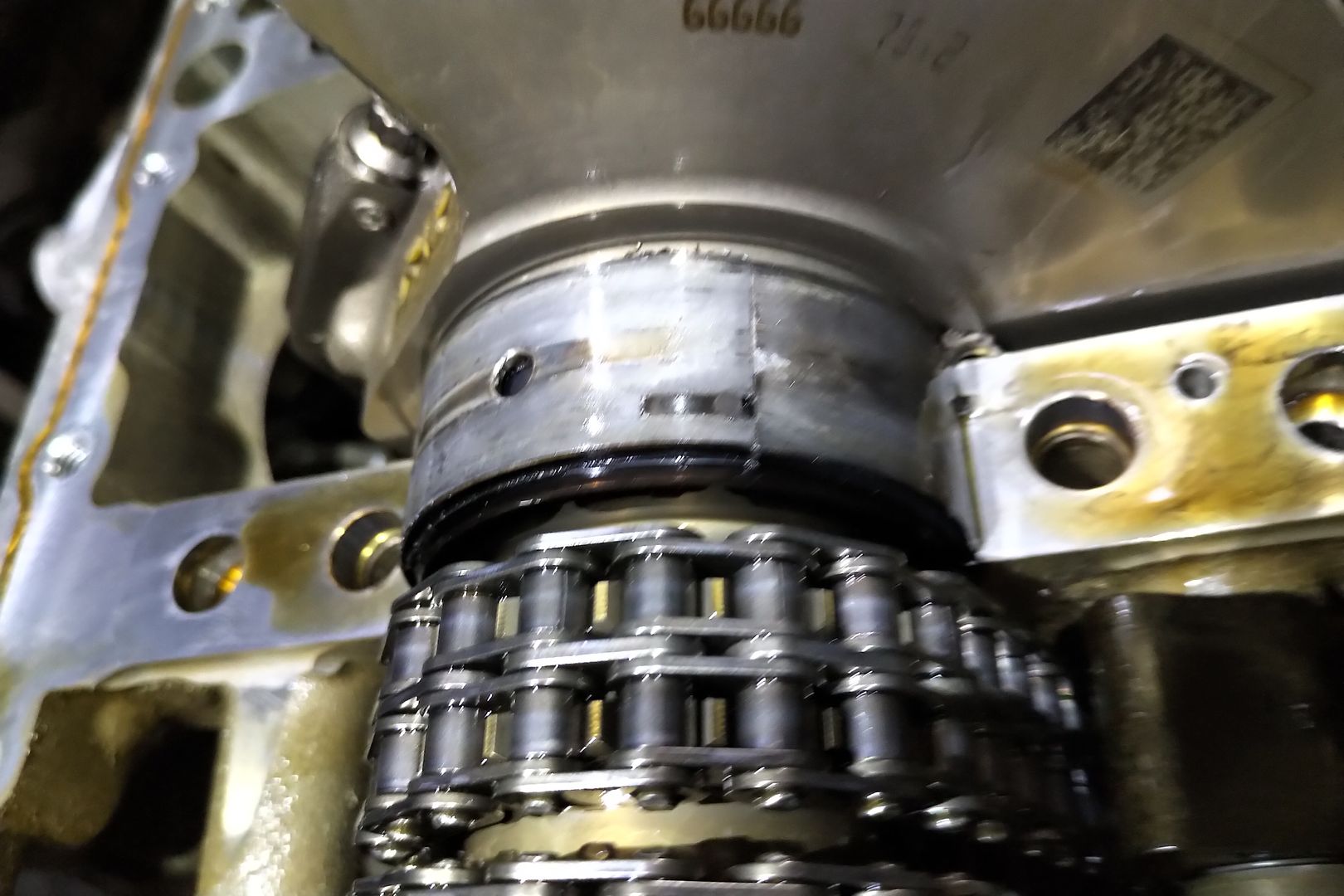

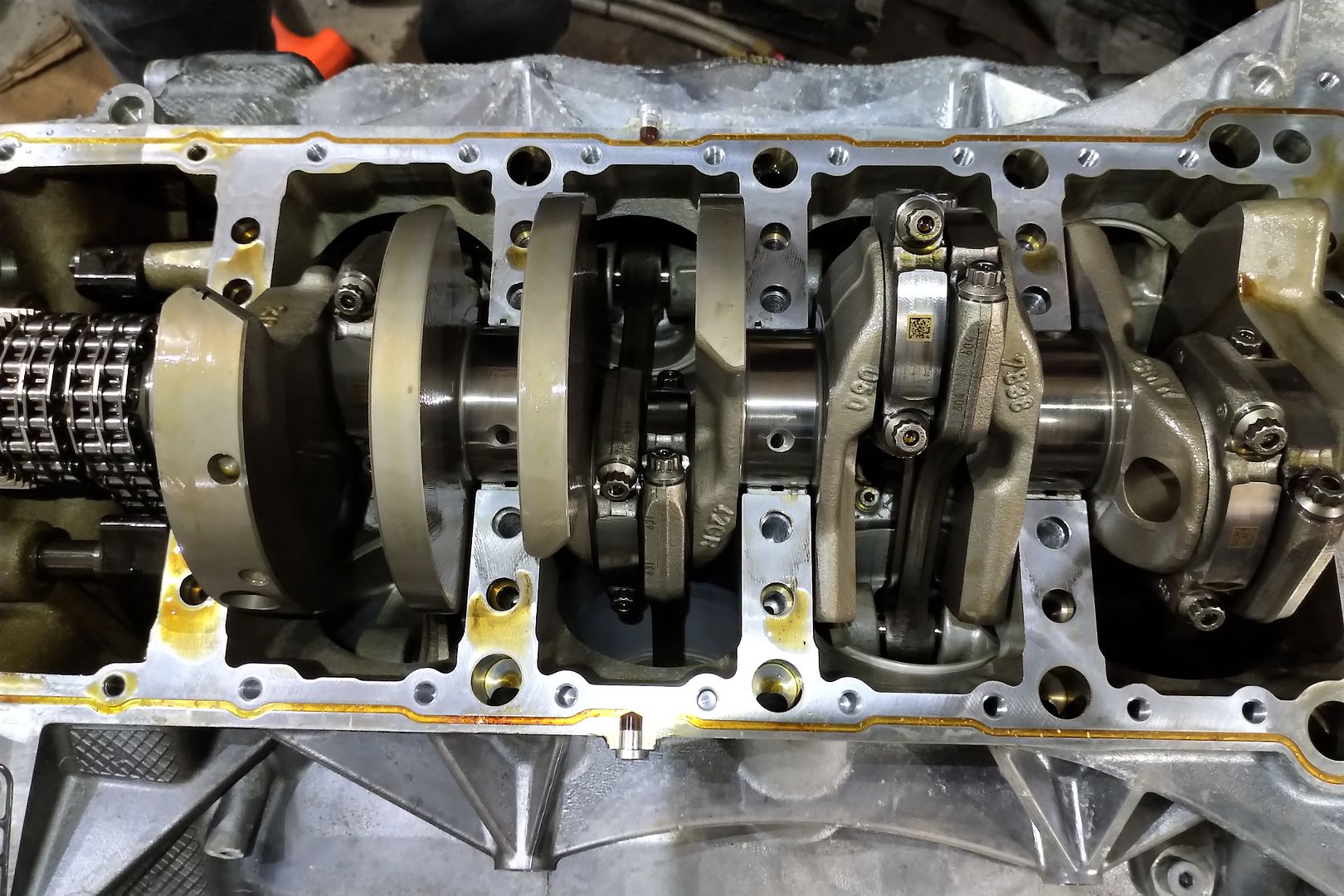

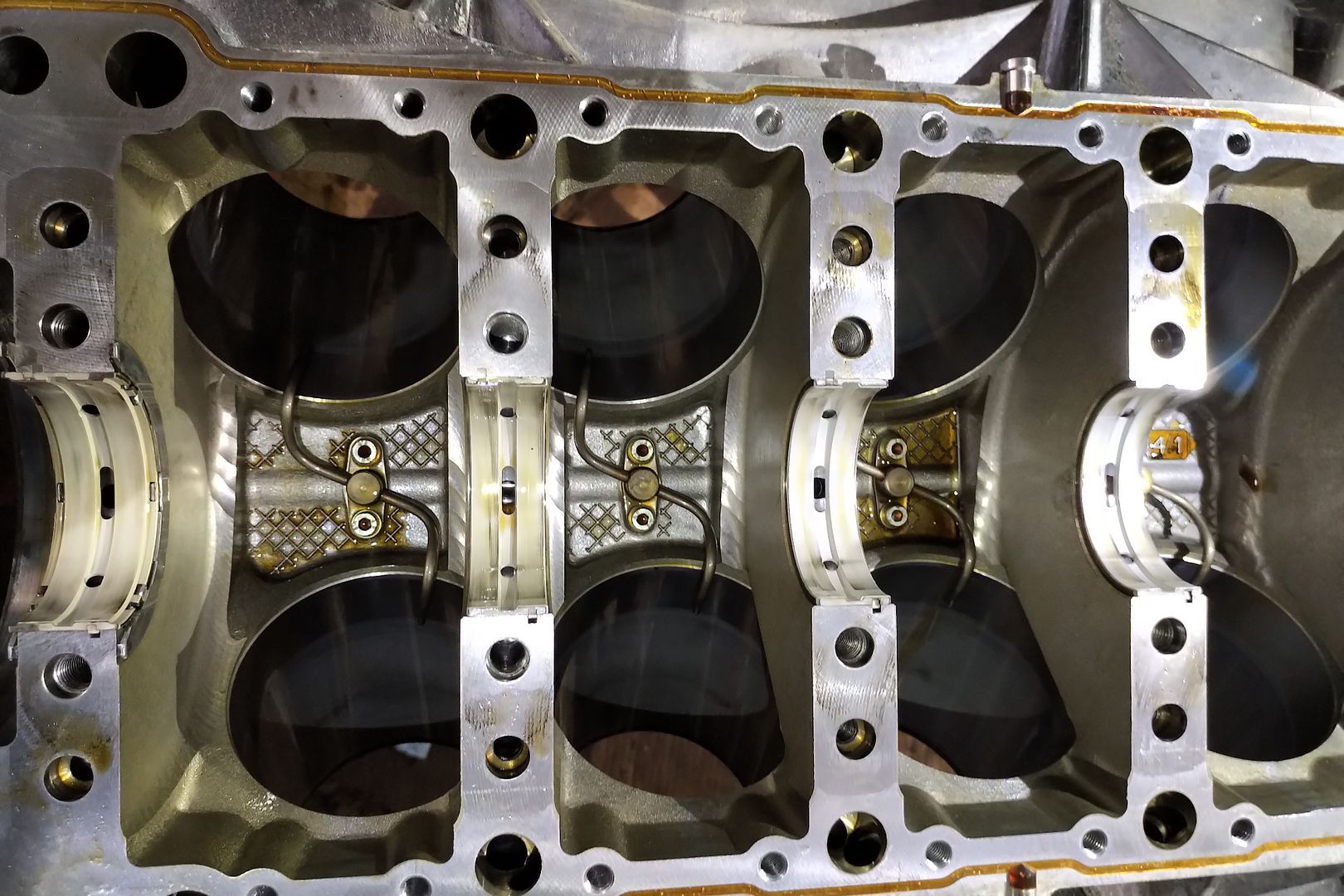

bedplate removed. When you do rod bearings you can see the iron inserts on the bedplate, but removing the bedplate you see how much iron is in there! Lots of it!

Main bearing #2 doesn't look particularly happy either

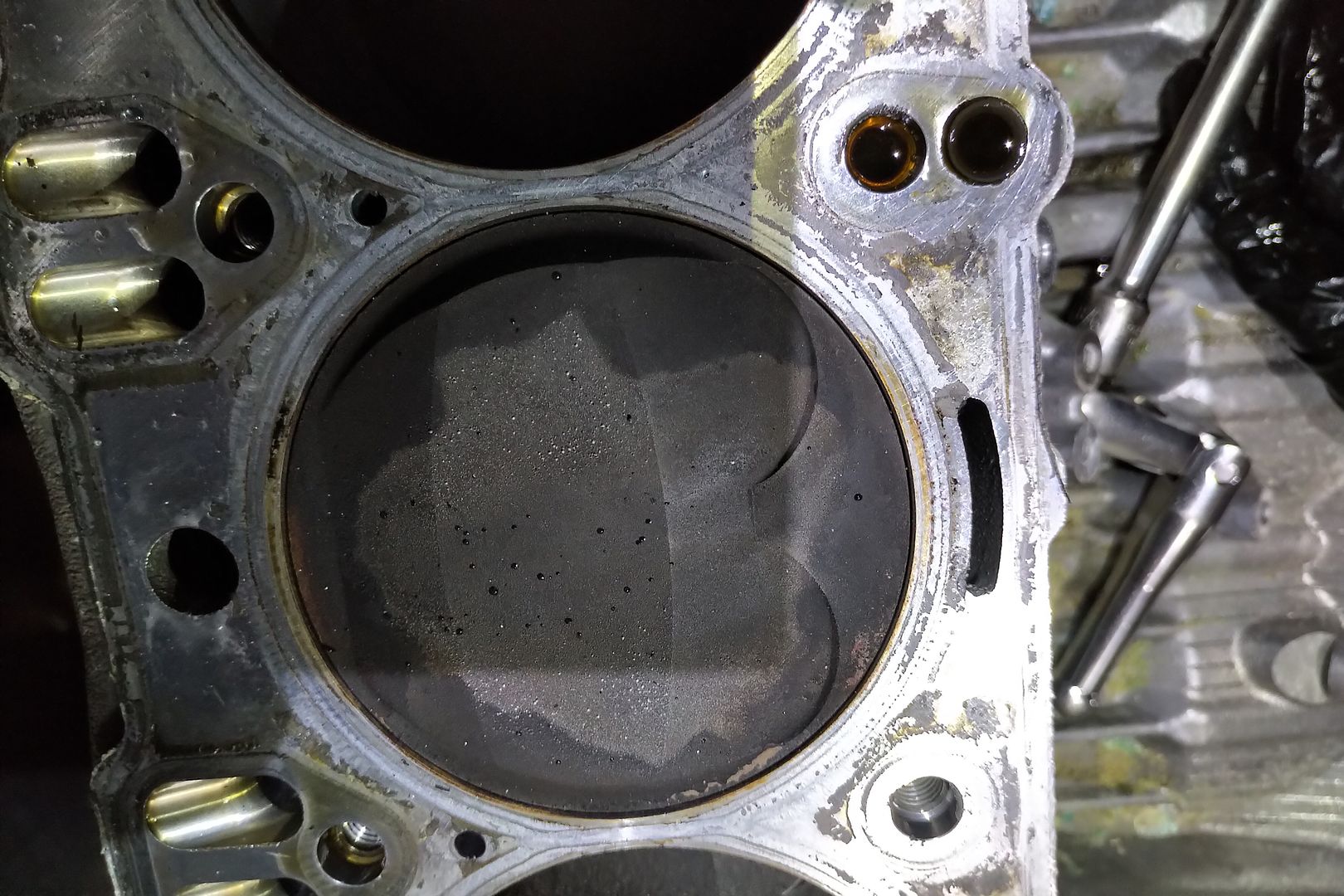

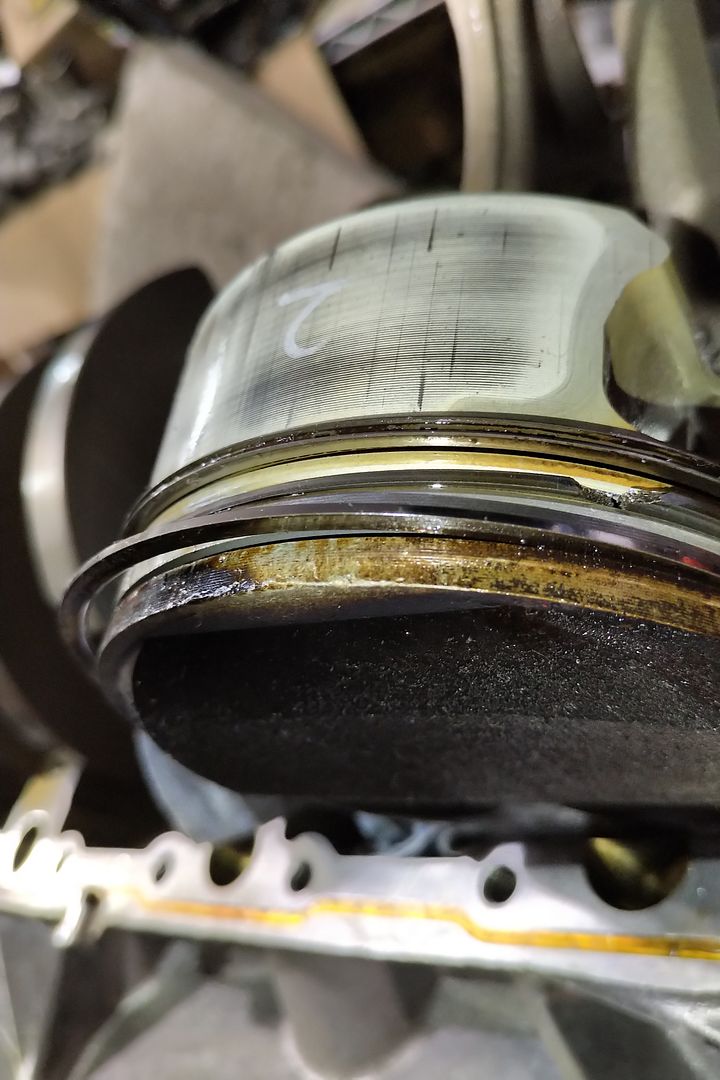

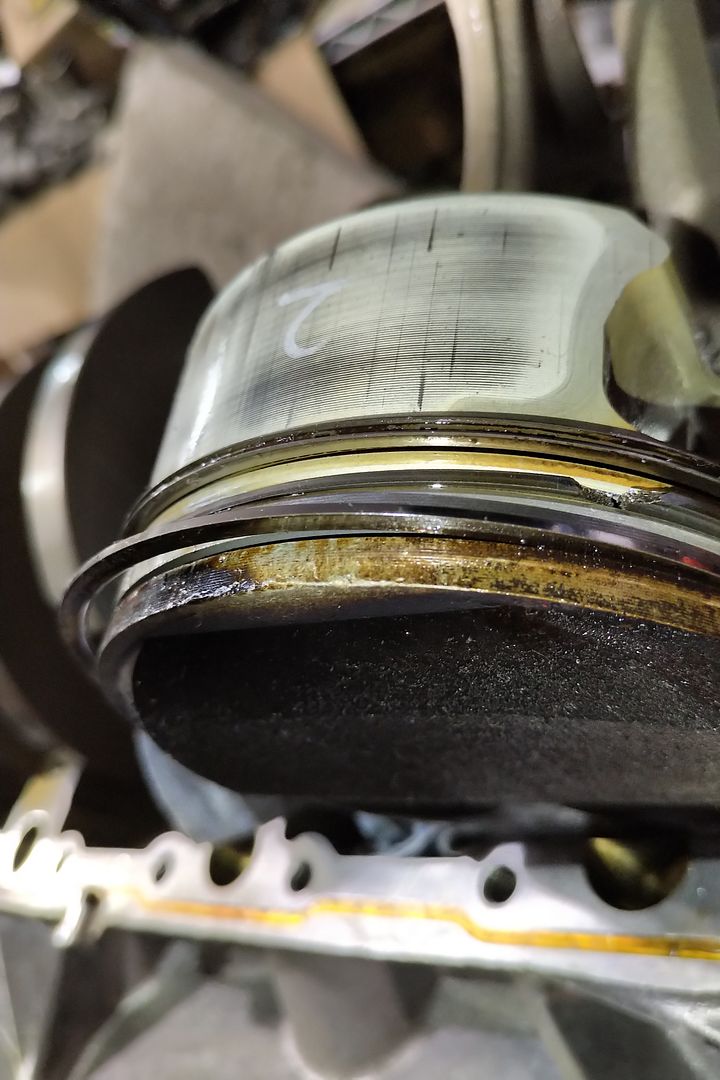

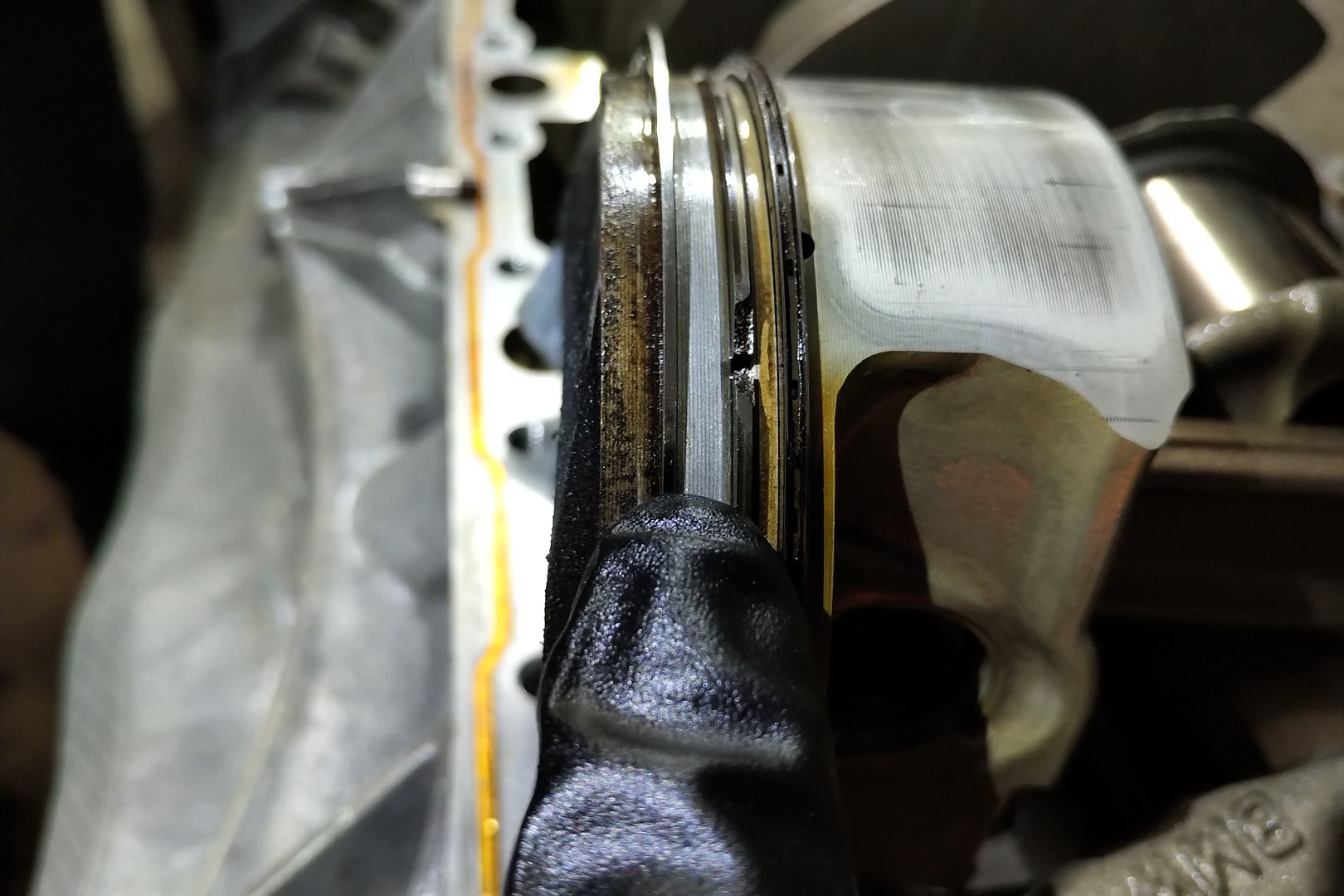

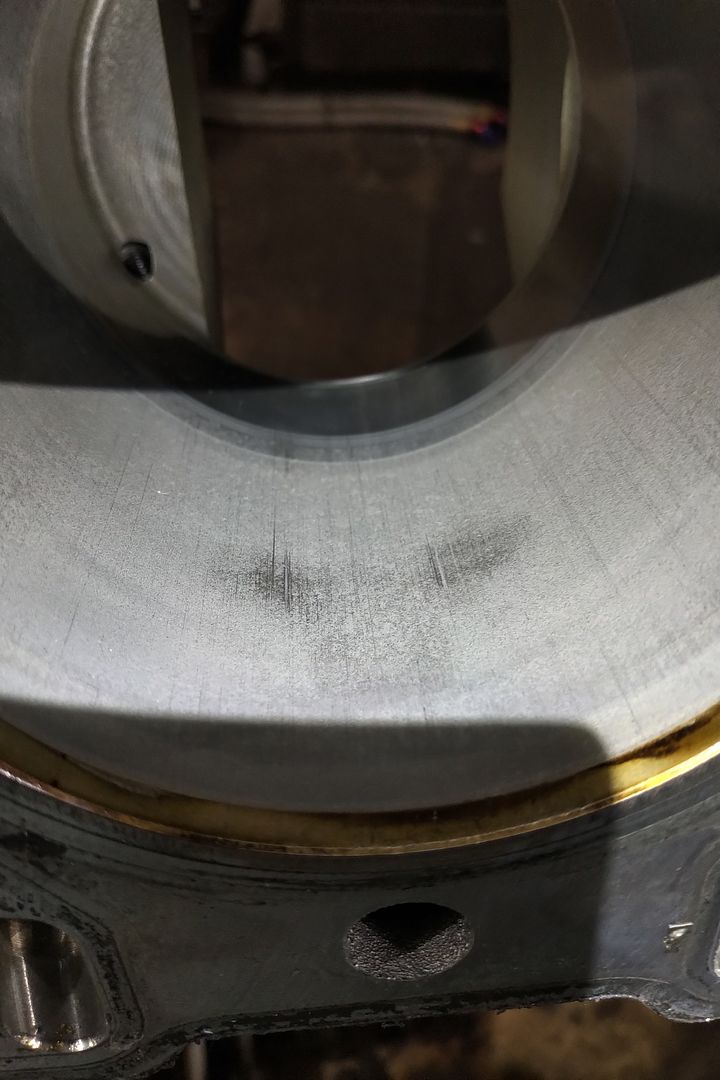

Look at how much detonation there is on this piston

Another piston, lots of detonation

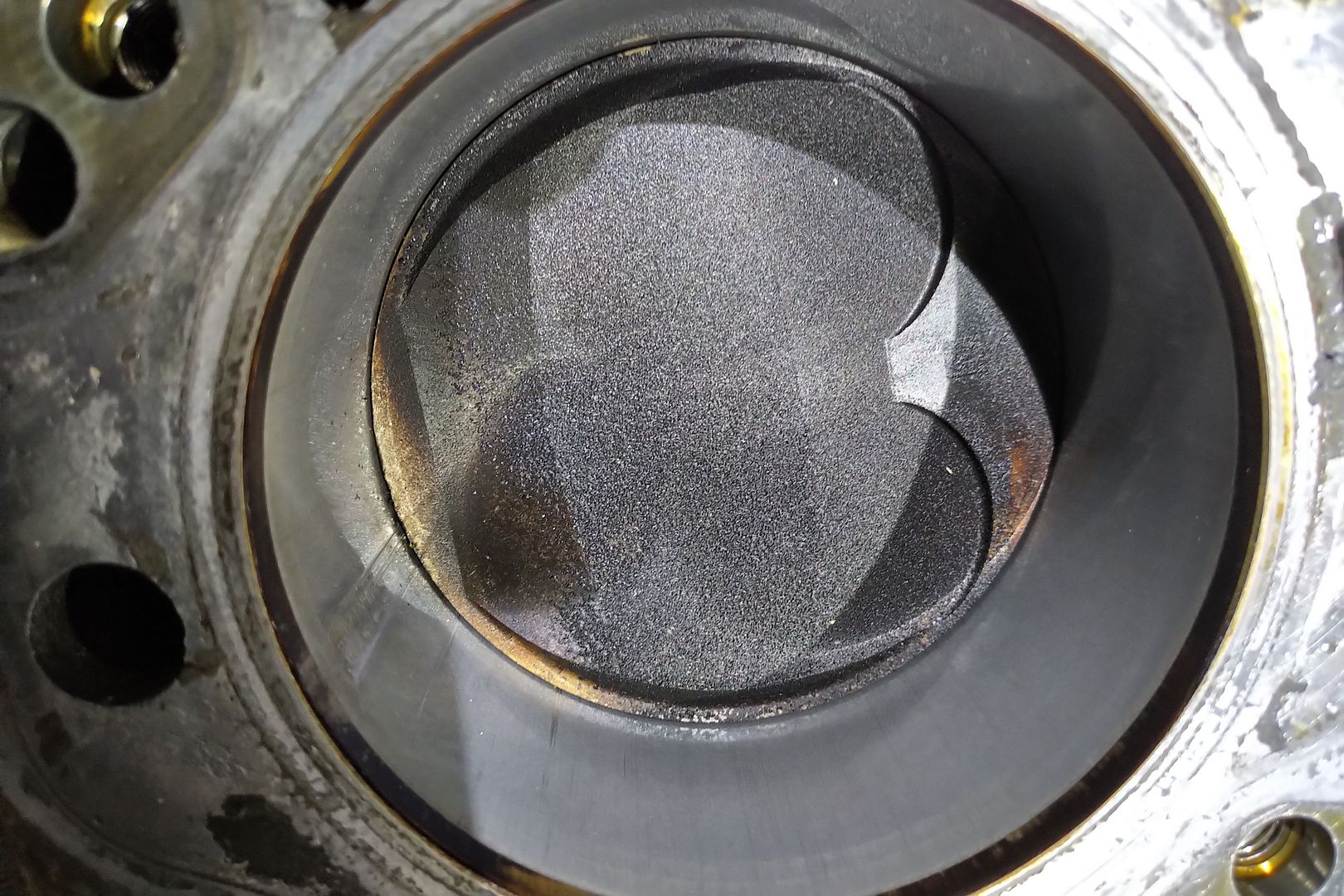

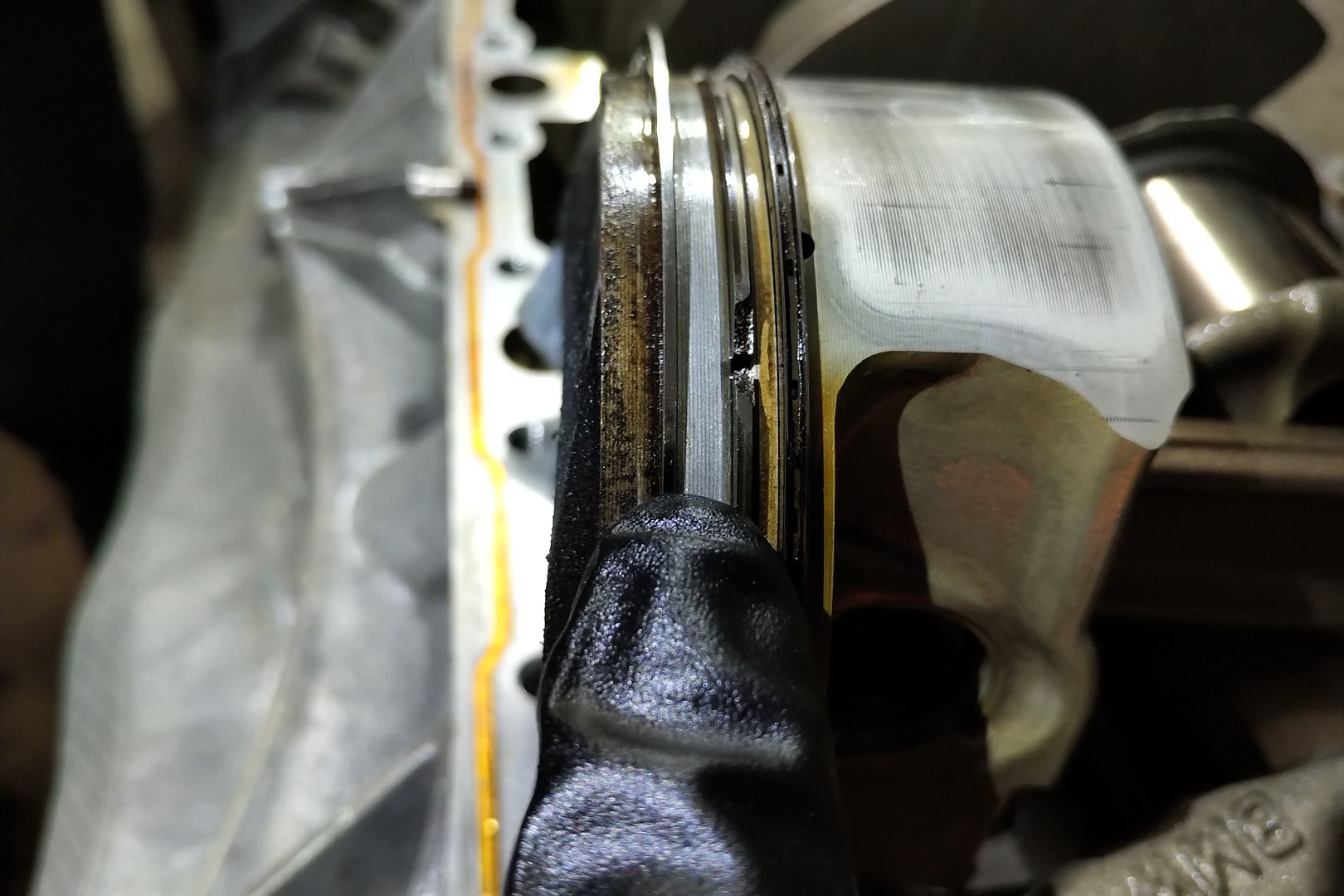

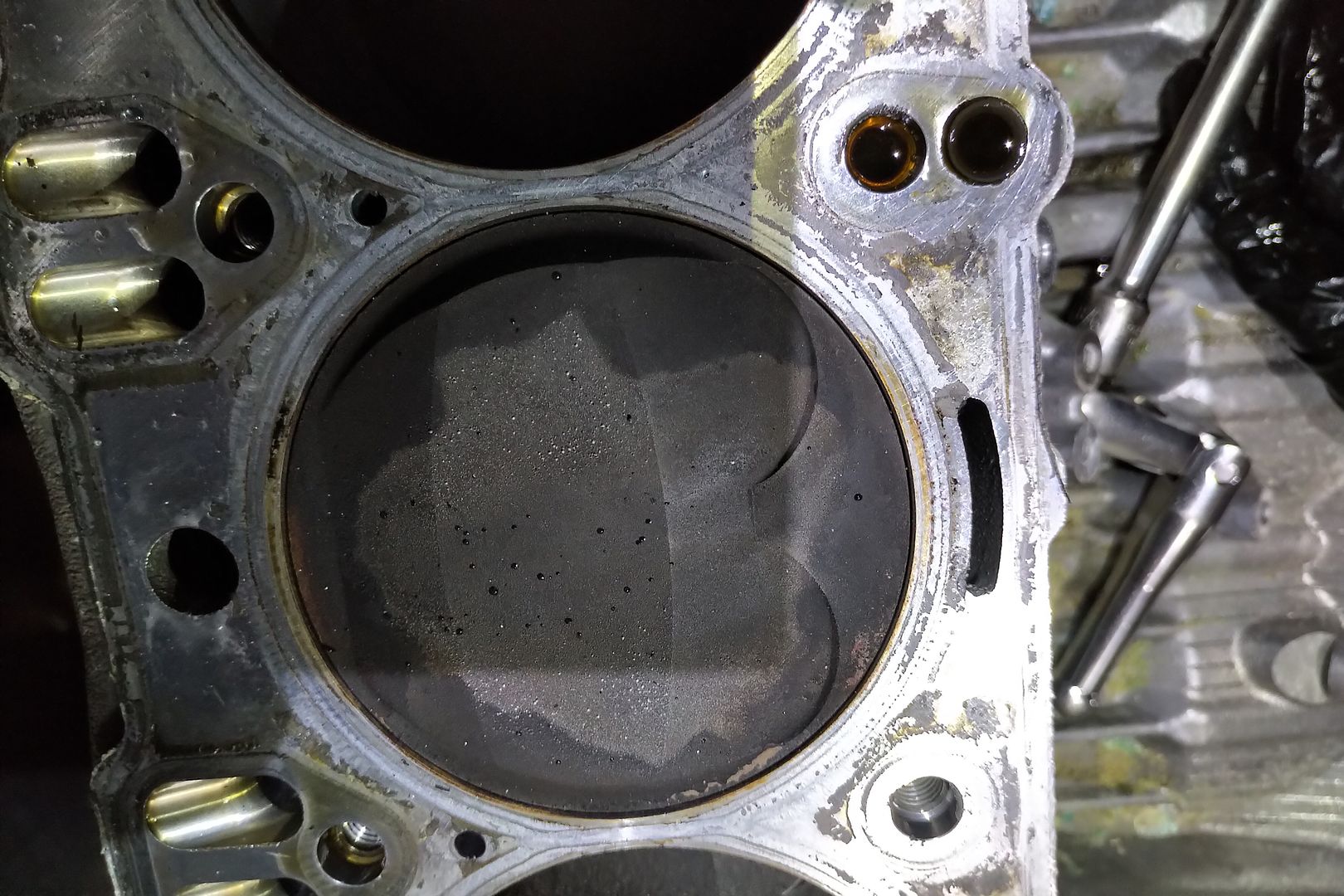

Broken ring besides lots of detonation

Broken ring

another shot of the broken ring

for reference, this sharp edge is what the piston should look like

this is where main bearing #1 goes. Note how it spun

Huge scratch in the cylinder wall. This is the same cylinder with the broken ring

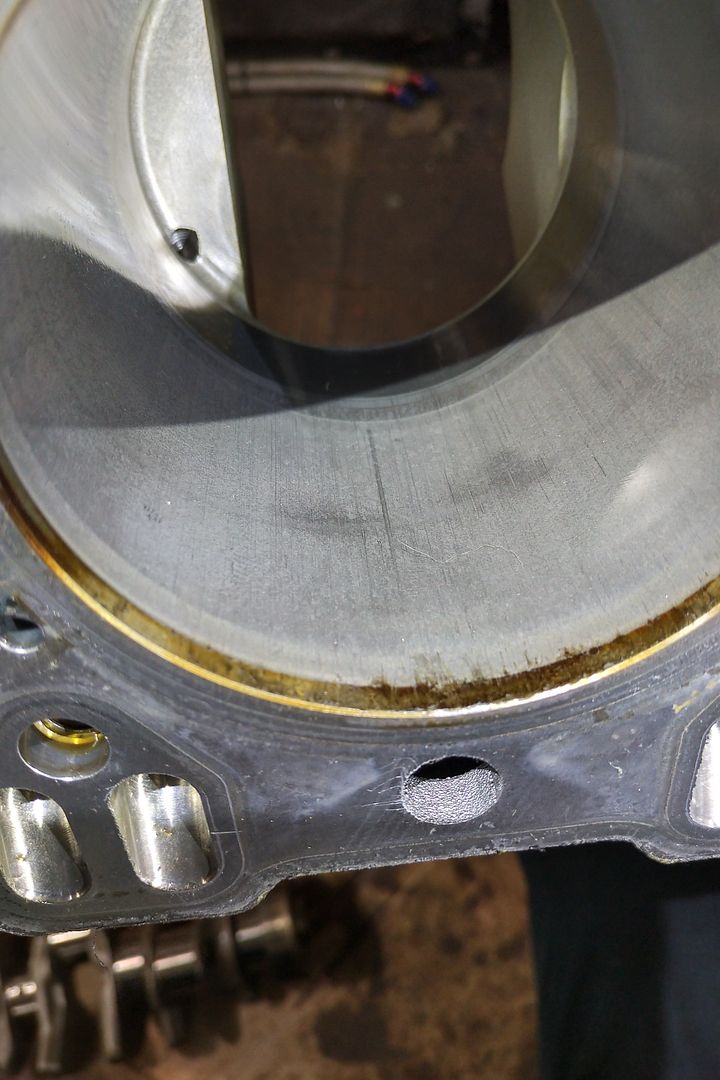

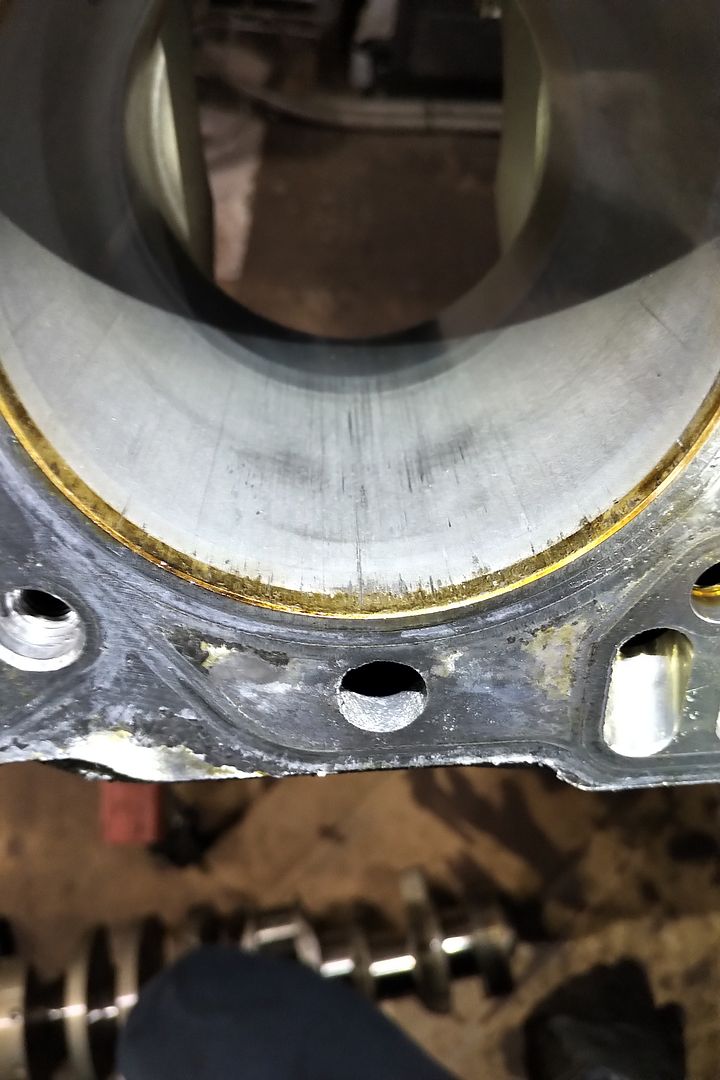

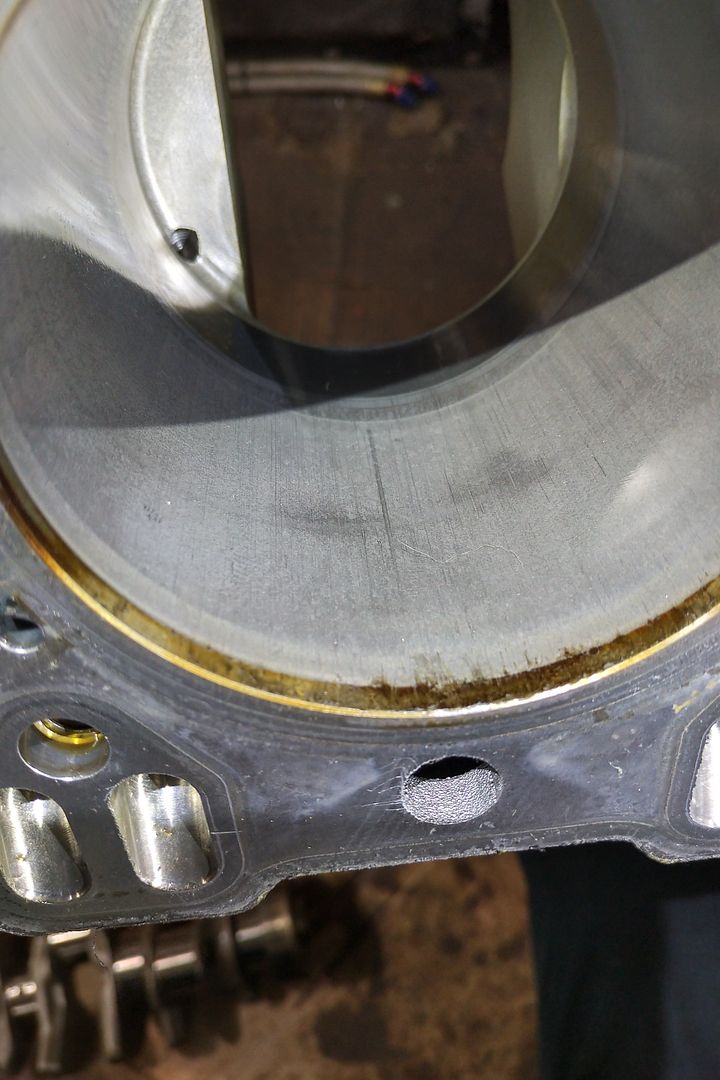

another cylinder

another cylinder

another one

another one

more scratches

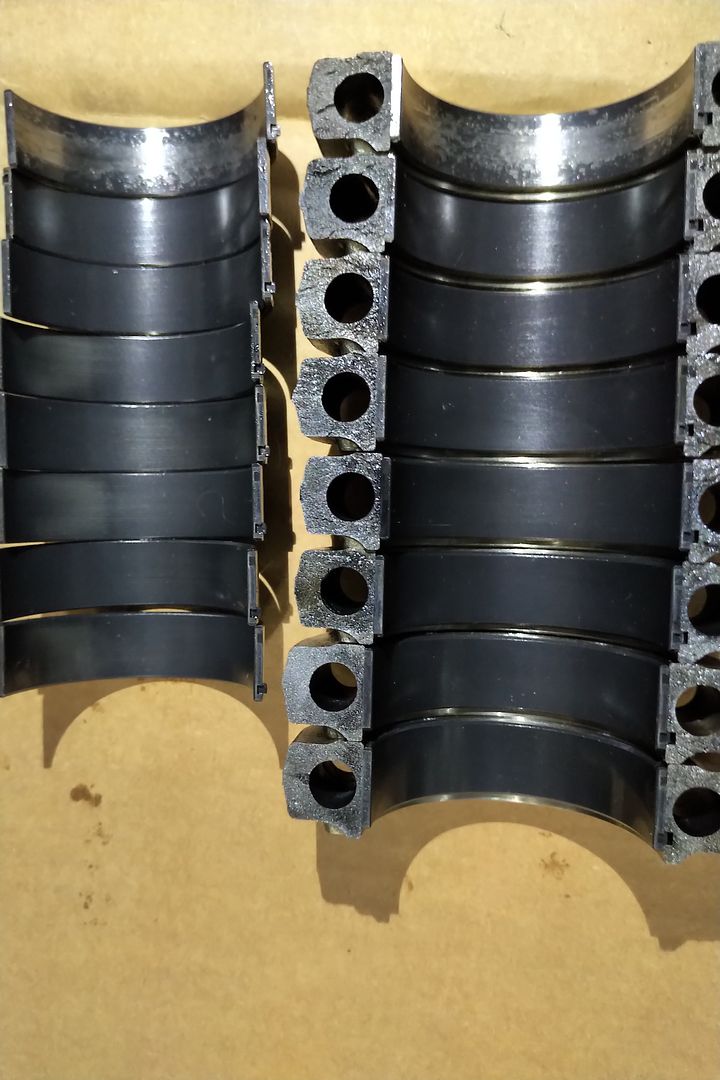

Finally, BE rod bearings. Looking good!!

A few things to note:

-Main bearing #1 seized, just as expected. It is welded around the crank

In our opinion this was to be expected. The engine drove for 2k miles while running horribly, so this imbalance wore all the bearings out

-The block did not crack

-Multiple cylinders show signs of lots of detonation

-One cylinder has a broken ring

-BE bearings on cylinder 1 are beat up. This is to be expected from the main bearing failure

-The rest of the BE bearings look incredibly good. The damage on the engine in general is serious, yet the bearings almost look new. Excellent results from BE bearings

Original blown engine thread:

Some background

We bought the car with 36k miles in 2016 as a dedicated track car. 2011.5 E90 M3 slicktop DCT as the only option, no nav, cloth seats, completely stock at the time.

The first weekend after buying the car we did rod bearings. This is the car of the rod bearing DIY

We kept the engine/exhaust stock for the first ~25k miles and two track seasons, modding brakes & suspension only.

Two track seasons are around 60 track days, but the car is double-teamed so the it sees twice as many sessions per day as a regular car. In other words, the engine has 120 normal track days on it.

After 25k miles and 120 track days days we added an Epic off the shelf tune. We specified a catless tune, however, when the track day rolled around our catless xpipe hadn't arrived so instead we opted to use our ESS HFC Xpipe from our E92.

That xpipe had survived plenty of track days on our other car.

In the first day, first session with the tune and the xpipe on the E90 we did a personal best at WGI with R1 tires (2:06.7) but the engine was 'not running right'. We forfeited the weekend because something was clearly wrong. It is as if the car were running on 7 cylinders, vibrating horribly.

We took it to several mechanics and ended up $10k out of pocket troubleshooting uselessly. The mechanics kept telling us to keep driving the car even though it felt like it was about to tear itself apart. Foolishly we followed their advice.

One day we decided to remove the xpipe and saw the cats were melted, completely blocking one of the banks.

We went back to the stock xpipe and the engine started working again, but now it smoked badly.

A third mechanic identified it as bad valve stem seals, so the engine was dropped and the seals were replaced.

While we were at it, we installed our 284 cams and BE springs as well as the BW LT headers and Karbonius airbox

As there are no off the shelf tunes for 284 cams we did what I had always vowed we wouldn't do and the car went to get custom tuned. RK is in Long Island and is relatively local.

The car went to RK, got tuned on their dyno, put down 412whp and then the engine seized.

Then it sat around for 2 years until we disassembled it

The results are surprising. I'm going to leave a couple posts open to @[AutoTalent](contact:25579), @[kawasaki00](contact:161320) and @[greeneggs](contact:246064) , @[CarBahn Autoworks](contact:372979) , @[deansbimmer](contact:259100) , @[jcolley](contact:25742)

You can see some fluid in the valley of the V8

The black 284 cams

Vanos unit

Head

detonation

removing the cams

notice how different the first cylinder is than the rest on the head

Massive scratch on the cylinder wall

More detonation

this is what you see in any rod bearing job

you can see the be-arp bolts here

removing bedplate

main bearing #1 spun :cry:

bedplate removed. When you do rod bearings you can see the iron inserts on the bedplate, but removing the bedplate you see how much iron is in there! Lots of it!

Main bearing #2 doesn't look particularly happy either

Look at how much detonation there is on this piston

Another piston, lots of detonation

Broken ring besides lots of detonation

Broken ring

another shot of the broken ring

for reference, this sharp edge is what the piston should look like

this is where main bearing #1 goes. Note how it spun

Huge scratch in the cylinder wall. This is the same cylinder with the broken ring

another cylinder

another cylinder

another one

another one

more scratches

Finally, BE rod bearings. Looking good!!

A few things to note:

-Main bearing #1 seized, just as expected. It is welded around the crank

In our opinion this was to be expected. The engine drove for 2k miles while running horribly, so this imbalance wore all the bearings out

-The block did not crack

-Multiple cylinders show signs of lots of detonation

-One cylinder has a broken ring

-BE bearings on cylinder 1 are beat up. This is to be expected from the main bearing failure

-The rest of the BE bearings look incredibly good. The damage on the engine in general is serious, yet the bearings almost look new. Excellent results from BE bearings

Comment