Continuing some of the discussion from this thread: https://www.m3post.com/forums/showthread.php?t=1695988

To prevent this post from being even wordier than it is, I’m assuming people have a basic understanding of flat ride, how it’s achieved, its benefits, and related concepts like ride frequency.

The above thread started with a simple question: Why is flat ride nonexistent among off-the-shelf coilover kits? Even for kits that let you specify your spring rates, the recommended and popular spring rates are never flat ride. And this seems to be true regardless of how street- or track-oriented the kit is. Ride frequencies always end up higher in front than in rear. No consensus in the aftermarket is that complete without good reasons, and any good reason is worth seeking.

To be clear, this post is not about "the answer" per se. I haven't found anything like a sufficient all-in-one-place explanation by an authoritative source, and while I'd love to read one, I don't expect one any time soon. The point is to try to lay out and discuss some of the dynamics that could explain the trend, largely because those dynamics are interesting in themselves. Hopefully we can generate some robust and respectful discussion on this stuff here.

I also do not mean to present myself as an expert on these topic. I'm an amateur like anyone else, trying to understand this stuff both for practical purposes (deciding on my own setup) and out of curiosity.

The thread linked above has some solid discussion on this topic. I’m incorporating some of that along with some stuff I’ve come across recently in the hopes that we can continue the conversation here.

1. Track-oriented cars tend to sacrifice flat ride, and not without reason

A lot of the discussion so far has focused on the fact that most E9x M3s that are fast on track tend to run higher ride frequencies in front than in rear. The reason could be any combination of:

2. Spring rates vs. front roll couple percentage (FRC %)

FRC % is basically how much of the car’s total roll stiffness (resistance to roll) is handled by the front axle. All else equal, increasing the FRC % increases understeer, and decreasing it shifts the handling balance toward oversteer. Because any responsible coilover manufacturer would want to be careful about adding too much oversteer, they probably want to avoid a significant decrease in FRC % vs. stock. In fact, because stiffer springs tend to produce sharper limit behavior, they may want to increase FRC % to retain a sufficient understeer bias.

I’m not sure what the FRC % is for our cars on stock suspension, but the exact number doesn’t matter here. What matters is that the rear springs contribute more roll stiffness than the front springs while the front sway bar contributes more roll stiffness than the rear bar, so the effects at least partly cancel each other out. This means FRC % has an interesting relationship to spring stiffness.

Let’s say you stiffen your front and rear springs by the same percentage without touching the sway bars. The bars are contributing just as much roll stiffness as before, but stiffening the springs has raised total roll stiffness. This means the bars (and thus their forward-biased stiffness ratio) account for a smaller slice of that total, while the ride frequencies (and thus their rearward-biased stiffness ratio) account for a bigger slice. The net effect is a lower FRC %.

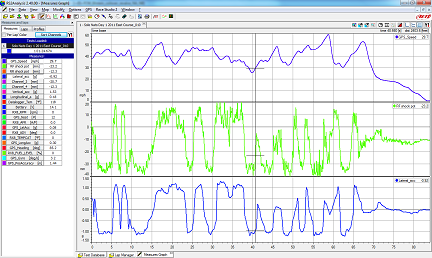

You can see this if you tinker with a decent suspension spreadsheet. It doesn’t have to be E9x M3 specific. I like Fat Cat Motorsports’s Ride Harmony spreadsheets (E46 M3 version here). Make up some easy spring rate numbers as a baseline, and then increase the front and rear spring rates by the same percentage while keeping everything else constant. As you do, you’ll see FRC % decreasing.

However, if you increase spring rates much more in front than in rear, you can keep FRC % from dipping too low without touching sway bars:

Kind of looks like an E9x M3 coilover kit now, doesn’t it? (much bigger increase at the front than at the back)

3. Lowering the front suspension increases body roll

This effect has been described ad nauseum, so I won’t pretend I can do better. The point is that when you lower the front suspension, as most people who buy coilovers will do, you need more front roll stiffness just to get body roll back to its old level, let alone to reduce it. And if you have to achieve that without necessarily changing sway bars – as coilover kits do – that adds to the need for stiffer front springs.

4. A flat-ride coilover kit would probably be harder to sell, especially as a mass-market off-the-shelf item

One option would be to raise spring rates minimally over stock to preserve flat ride without reducing FRC % too much. Can't imagine too many people would want to spend coilover money for stock-like spring rates.

Another option would be to either require an aftermarket front sway bar or incorporate one into the kit. Much more plausible, but more expensive and/or restrictive for reasons that most people would need explained to them.

And either way, it’d require buyers to accept more brake dive and possibly less lowering.

Shaikh Ahmad of Fat Cat Motorsports, the guy who is generally seen as the standard bearer for flat ride in the aftermarket, is sort of the exception that proves the rule. He builds flat ride kits all day... each of which is customized in every detail (spring rates, damper valving, bump stops, ride heights, etc.) to each particular car and its expected usage via a highly individualized consultation process. By the time customers find him, they probably either already like the flat ride principle or just believe in his expertise. If they have any questions or reservations remaining, the consultation process gives Shaikh a chance to educate them and earn their buy-in. Each kit can be optimized for a relatively narrowly defined set of parameters. The custom damper valving can have a significant impact on the performance of the kit, and can also facilitate side benefits like lower friction and more compliance in the dampers. And of course you pay more for the privilege. Very different situation from an off-the-shelf kit that's supposed to work as a one-and-done mod in a wide variety of cars and use cases.

Summary (so far)

If all of this is correct, it might be enough on its own to explain the lack of flat ride among coilover kits. The idea would be that coilover manufacturers want to make sure their kits:

The flip side is that if you’re willing to swap in a stiffer front sway bar, not lower the car much, and tolerate a bit more brake dive, it should be possible to get great handling (at least for the street) with a flat ride setup, and thus reap the related ride quality benefits. Hopefully we'll eventually get to see whether that pans out in practice for this platform.

To prevent this post from being even wordier than it is, I’m assuming people have a basic understanding of flat ride, how it’s achieved, its benefits, and related concepts like ride frequency.

The above thread started with a simple question: Why is flat ride nonexistent among off-the-shelf coilover kits? Even for kits that let you specify your spring rates, the recommended and popular spring rates are never flat ride. And this seems to be true regardless of how street- or track-oriented the kit is. Ride frequencies always end up higher in front than in rear. No consensus in the aftermarket is that complete without good reasons, and any good reason is worth seeking.

To be clear, this post is not about "the answer" per se. I haven't found anything like a sufficient all-in-one-place explanation by an authoritative source, and while I'd love to read one, I don't expect one any time soon. The point is to try to lay out and discuss some of the dynamics that could explain the trend, largely because those dynamics are interesting in themselves. Hopefully we can generate some robust and respectful discussion on this stuff here.

I also do not mean to present myself as an expert on these topic. I'm an amateur like anyone else, trying to understand this stuff both for practical purposes (deciding on my own setup) and out of curiosity.

The thread linked above has some solid discussion on this topic. I’m incorporating some of that along with some stuff I’ve come across recently in the hopes that we can continue the conversation here.

1. Track-oriented cars tend to sacrifice flat ride, and not without reason

A lot of the discussion so far has focused on the fact that most E9x M3s that are fast on track tend to run higher ride frequencies in front than in rear. The reason could be any combination of:

- More front roll stiffness for faster transitions and better exit traction (don’t want to rely too much on the sway bar for this);

- More support under braking; and/or

- More stable front aero performance (front aero tends to be highly pitch-sensitive).

2. Spring rates vs. front roll couple percentage (FRC %)

FRC % is basically how much of the car’s total roll stiffness (resistance to roll) is handled by the front axle. All else equal, increasing the FRC % increases understeer, and decreasing it shifts the handling balance toward oversteer. Because any responsible coilover manufacturer would want to be careful about adding too much oversteer, they probably want to avoid a significant decrease in FRC % vs. stock. In fact, because stiffer springs tend to produce sharper limit behavior, they may want to increase FRC % to retain a sufficient understeer bias.

I’m not sure what the FRC % is for our cars on stock suspension, but the exact number doesn’t matter here. What matters is that the rear springs contribute more roll stiffness than the front springs while the front sway bar contributes more roll stiffness than the rear bar, so the effects at least partly cancel each other out. This means FRC % has an interesting relationship to spring stiffness.

Let’s say you stiffen your front and rear springs by the same percentage without touching the sway bars. The bars are contributing just as much roll stiffness as before, but stiffening the springs has raised total roll stiffness. This means the bars (and thus their forward-biased stiffness ratio) account for a smaller slice of that total, while the ride frequencies (and thus their rearward-biased stiffness ratio) account for a bigger slice. The net effect is a lower FRC %.

You can see this if you tinker with a decent suspension spreadsheet. It doesn’t have to be E9x M3 specific. I like Fat Cat Motorsports’s Ride Harmony spreadsheets (E46 M3 version here). Make up some easy spring rate numbers as a baseline, and then increase the front and rear spring rates by the same percentage while keeping everything else constant. As you do, you’ll see FRC % decreasing.

However, if you increase spring rates much more in front than in rear, you can keep FRC % from dipping too low without touching sway bars:

Kind of looks like an E9x M3 coilover kit now, doesn’t it? (much bigger increase at the front than at the back)

3. Lowering the front suspension increases body roll

This effect has been described ad nauseum, so I won’t pretend I can do better. The point is that when you lower the front suspension, as most people who buy coilovers will do, you need more front roll stiffness just to get body roll back to its old level, let alone to reduce it. And if you have to achieve that without necessarily changing sway bars – as coilover kits do – that adds to the need for stiffer front springs.

4. A flat-ride coilover kit would probably be harder to sell, especially as a mass-market off-the-shelf item

One option would be to raise spring rates minimally over stock to preserve flat ride without reducing FRC % too much. Can't imagine too many people would want to spend coilover money for stock-like spring rates.

Another option would be to either require an aftermarket front sway bar or incorporate one into the kit. Much more plausible, but more expensive and/or restrictive for reasons that most people would need explained to them.

And either way, it’d require buyers to accept more brake dive and possibly less lowering.

Shaikh Ahmad of Fat Cat Motorsports, the guy who is generally seen as the standard bearer for flat ride in the aftermarket, is sort of the exception that proves the rule. He builds flat ride kits all day... each of which is customized in every detail (spring rates, damper valving, bump stops, ride heights, etc.) to each particular car and its expected usage via a highly individualized consultation process. By the time customers find him, they probably either already like the flat ride principle or just believe in his expertise. If they have any questions or reservations remaining, the consultation process gives Shaikh a chance to educate them and earn their buy-in. Each kit can be optimized for a relatively narrowly defined set of parameters. The custom damper valving can have a significant impact on the performance of the kit, and can also facilitate side benefits like lower friction and more compliance in the dampers. And of course you pay more for the privilege. Very different situation from an off-the-shelf kit that's supposed to work as a one-and-done mod in a wide variety of cars and use cases.

Summary (so far)

If all of this is correct, it might be enough on its own to explain the lack of flat ride among coilover kits. The idea would be that coilover manufacturers want to make sure their kits:

- Offer perceptible (and/or merely perceived) handling improvements;

- Are ready for some kind of track usage;

- Can offer benefits regardless of lowering (within reason);

- Don’t need aftermarket sway bars; and

- Don’t unnecessarily increase oversteer.

The flip side is that if you’re willing to swap in a stiffer front sway bar, not lower the car much, and tolerate a bit more brake dive, it should be possible to get great handling (at least for the street) with a flat ride setup, and thus reap the related ride quality benefits. Hopefully we'll eventually get to see whether that pans out in practice for this platform.

Comment