Originally posted by Rudbari

View Post

Announcement

Collapse

No announcement yet.

My 2005 Imola Red M3 6MT Build Journal

Collapse

X

-

Small world! Wonder which of my friends this was. Time to do some interrogating. Some of my close friends grew up there and were back visiting their families this past weekend.Originally posted by S3diment View PostI was pumping gas at a Shell (v-power for the gainz) today in Springboro and someone came up to me complimenting me on my car. He said that one of his friends had an Imola one up in Columbus, I took a guess and asked if this individual bought out of state and just did rod bearings. Turns out it was you that he was referring to! Small world!

Leave a comment:

-

I was pumping gas at a Shell (v-power for the gainz) today in Springboro and someone came up to me complimenting me on my car. He said that one of his friends had an Imola one up in Columbus, I took a guess and asked if this individual bought out of state and just did rod bearings. Turns out it was you that he was referring to! Small world!

- Likes 1

Leave a comment:

-

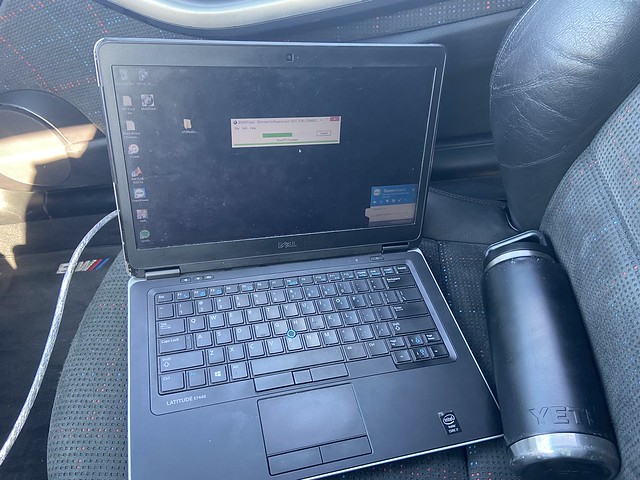

Shortly after the shift knob installation, I reached out to Hassan from HTE Performance Tuning to maximize the performance out of the OEM euro headers. I opted for a street tune rather than a dyno tune since this tune would be pretty generic and not require a lot of adjustments from base files Hassan has. I drove out into the country, used my phone as a hotspot, and Hassan connected into my laptop to go to work. Overall process was pretty quick and easy. Immediately I could feel a little more power in the middle and top of the RPM band. I also noticed that the tune runs a little rich which gives me a single pop between shifts under a hard load - I love it.

Next, I got together with one of my friends here in Columbus so that he could do a review video for his YouTube channel. This was the second time he has driven my car, I still want to get behind the wheel of his ZHP to see how different it is. I have driven his E92 comp and it is surprising to me how different his M3 feels compared to mine. For those interested, the video is in the link below:

https://www.youtube.com/watch?v=aFVe...tedPerspective

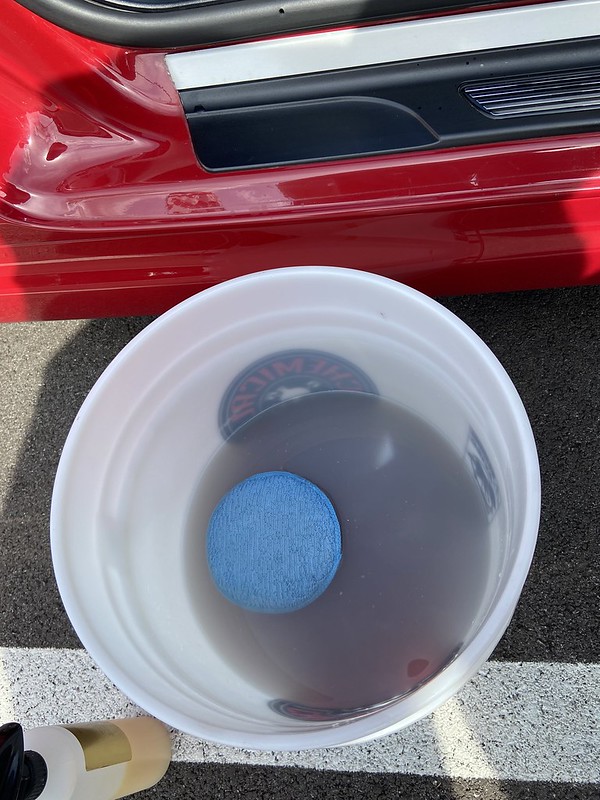

A week ago I went to the season opener for Dayton Cars and Coffee, which was the first show they have had since COVID started over a year ago. This show is always pretty big, but with the length of time from the last show it was huge with easily over 1000 cars. I left Columbus around 6am with a local E30 M3. Somewhere along the way I picked up a sheet metal screw in the passenger front tire. I decided to drive back to Columbus before removing it and plugging the hole since the tire was still holding air.

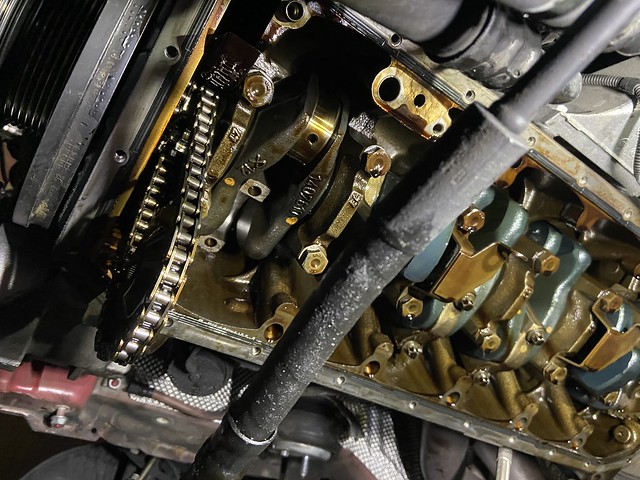

I have been mentioning it for a while, but it was finally time for me to service my rod bearings. This is my 2nd of the “big three” since I completed the VANOS overhaul last year. I was definitely nervous for the job ahead, but I kept telling myself that at the end of the day it is all just nuts and bolts. I read through all the DIYs over several times, printed out the full DIY and BMWs TSB for the job, and watched a few YouTube videos on people replacing the bearings to familiarize myself with the job ahead. I also contacted one of my college friends who worked at BMW of Louisville for a bit where he did some rod bearing jobs. He ended up leaving when ownership changed to go chase his dreams to become a commercial pilot. Timing worked out that he is currently working in Columbus as a Certified Flight Instructor while he gathers more hours.

I started out on my own taking care of all of the components that needed to be removed before dropping the subframe and removing the oil pan. Everything came off with ease as I expected since most of the components were removed over the winter when the OEM euro headers were installed.

Prior to dropping the subframe, I replaced the CPV o-ring with a new one from Mpower22. The old o-ring was definitely leaking and upon inspection after removal, it was hard as a rock. I also drained the transmission of the Redline fluid I put in last year and replaced it with OEM BMW transmission fluid. I also replaced the serpentine and AC belts and their tensioners because I didn’t think I had their age. As I went back through the prior owner’s records, the belts were replaced 3 years and 20k miles ago but I believe the tensioners were original. I’ll be sure to pay better attention to the records I have before replacing parts in the future.

Once my friend arrived, we dropped the subframe and oil pan and went to work.The first pair of bearings we did were cylinder 1 and 6, which in retrospect were not the best bearings for me to learn on because of the lack of space to access the rod side. I got the hang of the process and having a second set of trained eyes working on the installation process was comforting. I think I mentioned it before, but I did decide to use ACL bearings.

We moved onto cylinders 2 and 5 next, and then finally cylinders 3 and 4 before calling it a night around 1:30 in the morning. The bearings still looked decent, no signs of copper on any. As expected, there was more wear on the rod side than the cap side.

On Sunday everything was put back together. The oil pickup tube got a new o-ring (thank you BMWahba for checking over my parts list and noticing it was missing) and the oil pan was put back on. The engine mounts and steering guibo were replaced as the subframe was put back up. Before putting the reinforcement plate back on, we cleaned up the underside of the car to remove excess dirt and oil so a potential leak could be easily identified. At this time, we also pulled the fuse for the fuel pump and cranked over the motor using the starter only to prime the bearings and listen for any strange noises. Everything sounded great so the fuse was put back in and the engine was fired for the first time. I was confident in our work but still nervous. The motor sounded great and we brought the coolant level up to operating temperature before turning the car back off as the clutch fan hadn’t been reinstalled yet.

After reinstalling the rest of the components and dropping the car back on the ground, it moved out of the garage under its own power where we checked the oil level. A quick trip around the block proved that we had a successful rod bearing job and we shared a celebratory drink. Never again do I want to do rod bearings on the floor of a garage. My whole body was sore and I was exhausted. I do still think that the overall difficulty wasn’t too bad, it was just a very long service.

- Likes 2

Leave a comment:

-

I just saw the video of your car on instagram.. Im in love with the CSL intake sound on your car. Sounds 100% perfect. Keep up the fine modding bro.

Leave a comment:

-

Spring is almost here and with warmer temperatures and a few months away from the car I have been getting excited to get out and drive. Ohio saw a really warm (60 degree) last day of February. This was the perfect time for me to go tackle a couple small projects. My main task was to locate and eliminate a heat shield rattle that popped up after the header install. This gave me a pretty good idea of where to start. Sure enough the first spot I looked at was the source of the rattle. The header was touching the heat shield that covers the passenger side front control arm bushing. A slight bend to the heat shield and I was good to go. In the second photo you can see a little mark on the header from where it touched the heat shield.

I also had purchased some Solution Finish Black Plastic & Vinyl Plastic Trim Restorer over the winter. My main target was the weather stripping above the front windshield. I was so happy with the results that I also did the rubber around the sun roof and the rear window. To me it looks brand new, but I want to see how it holds up over time and through some washes. From what I have heard, it should stay for a while.

For my final “pre-spring” change to the car, I focused on the shift knob. Ever since I put on the ZHP knob, I felt like the car was missing one thing that makes an M car an M car: an illuminated shift knob. I personally couldn’t convince myself that a back lit shift pattern was worth $300+, especially if I wasn’t going to use the shift boot. I found a pretty solid eBay deal for a very slightly used F80 M3 knob. I figured I could sell off the ZHP knob I am currently using and the F80 shift boot and be pretty close to even.

I logged all of my steps in this DIY: https://nam3forum.com/forums/forum/m...tom-shift-boot

I wasn’t sure if the DIY had been created before but I couldn’t find anything on it. Anyways, here is the result. Exactly the same as before except it lights up!

- Likes 1

Leave a comment:

-

Been a while since I've been in here....love your interior update. That's a mighty fine E46!

- Likes 1

Leave a comment:

-

Napa is all smooth (no grains).Originally posted by DropTopKingM3 View Post

That steering wheel looks great! I wasn’t too impressed with the pic of the wheel he had on his site but yours look so much better. Perhaps picture quality ? Who knows.

Ive been on a quest to find a clean steering wheel to replace my Coby alcantara wheel.

What is the difference between OEM style grains and the nappa? Is the oem style grains have all of the little lines in it and the nappa is more fine finished ?

- Likes 1

Leave a comment:

-

That steering wheel looks great! I wasn’t too impressed with the pic of the wheel he had on his site but yours look so much better. Perhaps picture quality ? Who knows.Originally posted by Inizes View PostWith the weather warming back up, I spent the last month or so focusing primarily on the interior. The first thing I wanted to do was clean up the leather. The seats and wheel looked greasy and could use it, so I went with the trusty Leatherique. I have had good results with it in the past and once again it did wonders. I really wish I remembered to take photos for a before and an after. Trust me, it was dirty. The photo below is just from cleaning the passenger seat.

The seats all now have a matte finish and feel great. The steering wheel was also disgusting, but after cleaning I presented myself with a new issue. There was prior wear damage from 15 years of use at the 1 o’clock position. Cleaning all of the dirt and grease that had packed itself into the damage allowed the leather to begin breaking loose from the wheel. So my cleaning made 95% of the wheel look better, but made the damaged part worse. I reached out to Coby Wheel and ordered a nappa leather replacement. I was torn in between having the OEM style grains or the nappa - ultimately I chose nappa because of the finish and feel. Below is the OEM wheel on the left with the new nappa covered wheel on the right.

With the wheel being out of commission, I also took advantage of refinishing the slightly damaged lower steering wheel trim and the tired shifter bezel. Again, I neglected to take before photos. Texaz3 killed it and they look amazing. Would absolutely recommend him and may be sending some more trim pieces to him in the future.

I am extremely satisfied with how everything turned out! Car is starting to look new again and I love it.

I did run into one small issue and I am willing to share my failures. When I put the shift knob on, I hit the knob too hard. When I went out for my test drive I noticed the shifter was vibrating terribly in second gear. I immediately knew that I had popped the rear carrier bearing out of its spot. After getting under the car I confirmed my failure, luckily it only cost me about an hour of time.

For my (hopefully) last piece of maintenance and Inspection II, I needed to change the spark plugs. They were last changed at 71k miles, or roughly 32k miles ago. Everything looked pretty normal to me! Photo below of all of the old plugs, with cylinder 6 on the left and cylinder 1 on the right.

And here is a comparison to new…

In the future I will be changing the coil packs as they are getting up there in age and are due. For now I am content though.

Ive been on a quest to find a clean steering wheel to replace my Coby alcantara wheel.

What is the difference between OEM style grains and the nappa? Is the oem style grains have all of the little lines in it and the nappa is more fine finished ?

Leave a comment:

-

Very cool build! I love Imola red, I was originally looking for one myself. The exhaust with both resonators sounds way better than before

Leave a comment:

-

I alluded to it in my last update, but I wasn’t 100% satisfied with my first attempt of an exhaust setup. I was left with a loud resonance between 2,500-3,000 rpm, which is right about highway cruising speed. I couldn’t have avoided this rpm band and I definitely wasn’t going to live with it. Based on some videos I had seen online, I decided my first attempt at a fix would be dual OEM section 1 resonators. Most people would just source one additional section 1 and cut up their original. I want to keep as many original parts as I can with the car (that aren’t worn out) so I sourced 2 new section 1s to cut up. The first one was a Facebook Marketplace find in Cincinnati for $50. Finding the second one local turned out to be a harder task than I originally thought. I made some calls to some junk yards around the state based on what was listed on car-part.com. All of these leads turned out to be dead ends. I next turned to eBay and found almost every listing wanting about $150, I was surprised. I knew there was no way these were selling fast enough for every listing to be comfortable getting their asking price, so I went after the “Make an Offer” listings and began my bidding. Surly enough one of the listings that was originally $170 accepted my $50 offer and even had free shipping. So, for a grand total of $100 I had two section 1s to cut up.

The grinding of the welds was pretty easy. I made the mistake of not using ear protection when grinding apart the first one. Definitely use ear plugs, your hearing will thank you.

Trying to fit the dual resonator setup in the car was a bit more difficult than I was expecting. They definitely do fit, but there is a little bit of contact near the “S” bend. I found the passenger side piece to be the tightest squeeze, but I also put it in second to that may have been the cause. I would try it in the opposite order (passenger side first, then driver) and see if it has similar results the next time I drop the exhaust.

So now my setup is the following:

OEM Euro Headers (Catless)

Dual OEM resonator Section 1

Supersprint Resonated X-pipe Section 2

Rogue Engineering El Diablo Section 3

Here is the accompanying short video of the current exhaust setup: https://youtu.be/bTm5cbSX_uw

I found that this removed all of that nasty drone I was having from 2500-3000 rpm. I didn’t notice too much of a difference other than that.

I also decided to make a comparison video of the low end where the drone was as well as the top of the power band. That video is here: https://youtu.be/grfy8kFwtwk

To me, the top of the power band sounds the same, so I feel as though my goal was accomplished.

With the help of ECUWorx, I also tuned out the post cat O2 sensors and the EGT sensor out. This removed the CEL light off the dash which would drive me nuts. For now, I decided to leave in the "cat heating sequence" so that I would still have a true cold start. For the giggles, I added in the shift light programming and also removed the 155mph speed limiter. Will I ever go that fast? No. But its fun to do I guess.

I also tackled another very minor project recently. While I was vacuuming the driver side footwell, I noticed there was a tear in the clutch pedal pad. Knowing that these pedal pads arent very expensive, I figured they could both be replaced.

Old in on the top, new in on the bottom. Not a huge difference but the tear is gone and the car is slowly getting back to factory fresh.

Last edited by Inizes; 01-14-2021, 06:36 AM.

Last edited by Inizes; 01-14-2021, 06:36 AM.

Leave a comment:

-

I told myself I was going to be done working on the car for 2020, but for some reason I made an excuse that exhaust would be acceptable and the last thing. This time I really am going to stick to it though. I was scrolling through eBay and stumbled across a set of OEM Euro Headers for sale in Spain, the price was about $520 shipped to my door. This felt like a pretty good deal, but I wasn’t set on whether or not I should use these or go with Megans. Ultimately I decided OEM Euro seemed to fit the theme of my build a bit better since I have been lightly using the term “OEM+.”

They arrived pretty much as I expected. I thought they were a bit dirty so I cleaned them up in the sink to remove some of the surface dirt to make the installation process a little cleaner. I also removed one of the old compressible donut gaskets to fully prepare it for installation.

Black Friday made for some pretty solid deals from ECS Tuning on Supersprint Exhaust products. I had my eyes set on a SS Resonated X-pipe. Free shipping and the cheaper Black Friday pricing made this a better deal than Status Gruppe’s resonated X-pipe. Plus, shipping from 2 hours away in Ohio vs across the country from LA lowered the chances of shipping issues or damage.

Now that I had the headers and a section 2, it only made sense for me to find the final of the piece I was looking for, right? I knew from some videos I had seen from Instagram and YouTube that I wanted to try the Rogue Engineering El Diablo section 3. Unfortunately, they seem to be very difficult to get your hands on one. I woke up one morning and scrolled through Facebook. One of the first posts I saw was a post only a few minutes old for an M3 being parted out at TySpeed in New Jersey. That car had an El Diablo on it so I messaged to inquire and I was told the price was $600, with another $100 for shipping. I’ve seen these sell for a closer to $900-1000 so I thought it was a no brainer to buy it. Even if I used it and didn’t like it, I could easily get back out of it. Once it arrived, I noticed there was a bit of a minor issue that I had not been told about. However, the seller wasn’t aware of it either. On the driver side exhaust tips, there were a couple of cracks that had formed.

I swung by Go Fast Engineering in Powell, OH to quickly get the cracks welded up. Ryan was a huge help for fitting me in quickly. I forgot to grab after photos, but the cracks were drilled at either end to prevent spreading and then filled the crack in.

I have taken the section 2 off previously, so that wasn’t too bad of a job to take off. I thought it would be better to take this off first to help make taking off the muffler easier. I have heard that the stock section 3 was heavy, but wow 60 lbs feels heavier when you are trying to drop it by yourself and your floor jack isn’t tall enough to help support you. I think the weirdest part is how the weight is distributed and the awkward shape. I don’t think the muffler has ever been off the car, so I got pretty dirty.

I mounted up the section 2 and section 3. I didn’t bolt section 2 to section 1 right away so that I could remove section 1 while installing the headers.

I had read through the header install DIY in the forum and watched a few videos, but I was still nervous for some reason. More-so than the VANOS job I had performed earlier this year. I started my removal of the SAP and disconnected the coolant hose to the expansion tank. I was able to keep the smaller somewhat hard line from the expansion tank attached and rested the tank on the air intake plenum. I did clean up every part that I removed from the car, so I have lots of clean heat shields that nobody will ever see… but I know haha.

The only issue I had with the header install DIY was it didn’t specify what size corks to use to plug the two coolant holes. I bought an array from Lowe’s and here were the two sizes that I used.

My header installation went nearly flawless. My only issue is I had one stud come out of the block, so I needed to go purchase one from the nearest BMW dealership. $6 later I was back in business. I was lucky and had 2 friends come out and help me with this job. I think the ideal number of people for this job is two total. One person on top getting to most of the header nuts with a flex head socket, and one person under the car guiding the socket to the nuts the person on top can’t see. If I remember correctly, there were only 2 or 3 nuts I had to get from the bottom.

Putting everything back together was pretty easy. The first start up was louder than I expected and smelled due to some of the spilled coolant burning off. The first drive felt like pure bliss, I could have driven my car all night. The next morning I gave it another shot and started to realize that while the exhaust sounds great above 3,000 rpm, my current setup has a flaw. Between 2,500-3000 rpm, there is an awful drone/resonance that I will need to work on removing, especially since this is basically cruising speed on the highway. I have a fix in the works, so my next update will hopefully be that solution. Below is a video I put together of the current set up.

https://youtu.be/Xp6v7rPU8wsLast edited by Inizes; 12-23-2020, 07:20 AM.

- Likes 1

Leave a comment:

Leave a comment: