Just a little background for those that aren't too savvy with SMG functionality, the above SW re-flash is designed to take advantage of the more aggressive and faster CSL SMG controller shift logic.

Since gear shifts are a timed synchronous event between both DME and SMG controller, to really take advantage of true CSL shifting we need to address the engine controlled portion of the event. What we end up with is around 18 maps that need to be snatched from the CSL engine SW, overwriting your current maps.

First are the up-shift recognition maps that establish values based on driver demand torque (you pressing the gas) & engine speed for both Comfort and Sport modes. There's one each for regulated speed control, gear change, and full turn-on (torque ramp) for a total of six.

The next set of maps are for downshifting, with their values based on deceleration rate (fps) and engine speed. Total

of six as well.

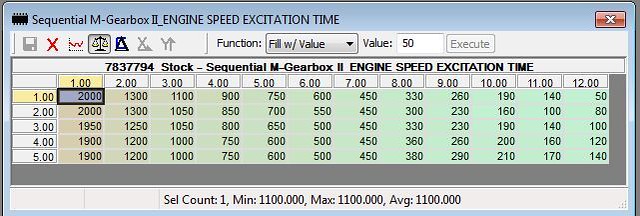

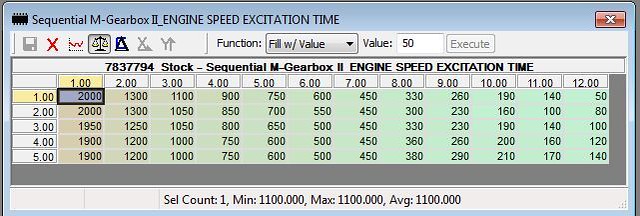

The next, more important set of maps, control the actual timing of engine speed regulation and torque ramp-up based on the recognition maps above. These also work in conjunction with the faster SMG controller logic to really shorten that timed synchronous shift event. To put it in perspective, shift logic '3' on this set-up feels more like shift logic '5' on normal ///M's.

Of note, eng. speed regulation is the same between normal ///M's and the CSL, however the torque ramp-up time is considerably shortened, nearly cut in half in some areas.

CSL

NORMAL RAMP-UP

These maps took a bit of figuring out but they are the ever-so-popular rev-match parameters. They serve as an applied percentage to target engine speed based on deceleration rate (fps) and current rpm. As you can see the normal maps top out around 60% applied engine speed, while the CSL tops out @ 100% applied engine speed. Also, the target engine speed threshold is referenced via a 3x0 function map with 400, 500 & 1000 rpm values.

CSL

Note: My Sport map is modified but normally both these maps are identical.

NORMAL ///M

KL_SMG_MOT_J_MOTOR:

What is it?

It's the Mass Moment of Inertia at various engine speeds, in newtons divided by meters per second squared.

Why do we need it?

It quantifies the required torque needed to change angular velocity of pretty much the entire drive line, from the flywheel to the rear wheels.

How is it used in calculation?

It is multiplied by the speed gradient (angular velocity) of the engine, which is rpm/sec -or- radians a second.

So for instance, let's say our speed gradient is 550 rpm/sec (31,625 degree's crank rotation; 87 revolutions per second; 5270rpm) When we apply a mass moment of 0.27 <--(S54 standard value) we come up with the following: 550 * 0.27 = 148.5 Nm required to change angular velocity. There are other values that are added as well that account for drag torque & consumer torque (AC compressor, alternator, H2O pump, etc.).

SEQUENTIAL M-GEARBOX II_MOTOR INERTIA

The above pic shows the difference between standard & euro ///M's, and the CSL. As you can see, after about 3200 rpm the value drops considerably while the CSL is still climbing. So let's quantify the effects of the differences by using the math formula above.

CSL:

1520 = 17.38 Nm

3000 = 125.22 Nm

6000 = 313 Nm

Standard and Euro:

1520 = 3.17 Nm

3520 = 73.46 Nm

5000 = 62.61 Nm

Since gear shifts are a timed synchronous event between both DME and SMG controller, to really take advantage of true CSL shifting we need to address the engine controlled portion of the event. What we end up with is around 18 maps that need to be snatched from the CSL engine SW, overwriting your current maps.

First are the up-shift recognition maps that establish values based on driver demand torque (you pressing the gas) & engine speed for both Comfort and Sport modes. There's one each for regulated speed control, gear change, and full turn-on (torque ramp) for a total of six.

The next set of maps are for downshifting, with their values based on deceleration rate (fps) and engine speed. Total

of six as well.

The next, more important set of maps, control the actual timing of engine speed regulation and torque ramp-up based on the recognition maps above. These also work in conjunction with the faster SMG controller logic to really shorten that timed synchronous shift event. To put it in perspective, shift logic '3' on this set-up feels more like shift logic '5' on normal ///M's.

Of note, eng. speed regulation is the same between normal ///M's and the CSL, however the torque ramp-up time is considerably shortened, nearly cut in half in some areas.

CSL

NORMAL RAMP-UP

These maps took a bit of figuring out but they are the ever-so-popular rev-match parameters. They serve as an applied percentage to target engine speed based on deceleration rate (fps) and current rpm. As you can see the normal maps top out around 60% applied engine speed, while the CSL tops out @ 100% applied engine speed. Also, the target engine speed threshold is referenced via a 3x0 function map with 400, 500 & 1000 rpm values.

CSL

Note: My Sport map is modified but normally both these maps are identical.

NORMAL ///M

KL_SMG_MOT_J_MOTOR:

What is it?

It's the Mass Moment of Inertia at various engine speeds, in newtons divided by meters per second squared.

Why do we need it?

It quantifies the required torque needed to change angular velocity of pretty much the entire drive line, from the flywheel to the rear wheels.

How is it used in calculation?

It is multiplied by the speed gradient (angular velocity) of the engine, which is rpm/sec -or- radians a second.

So for instance, let's say our speed gradient is 550 rpm/sec (31,625 degree's crank rotation; 87 revolutions per second; 5270rpm) When we apply a mass moment of 0.27 <--(S54 standard value) we come up with the following: 550 * 0.27 = 148.5 Nm required to change angular velocity. There are other values that are added as well that account for drag torque & consumer torque (AC compressor, alternator, H2O pump, etc.).

SEQUENTIAL M-GEARBOX II_MOTOR INERTIA

The above pic shows the difference between standard & euro ///M's, and the CSL. As you can see, after about 3200 rpm the value drops considerably while the CSL is still climbing. So let's quantify the effects of the differences by using the math formula above.

CSL:

1520 = 17.38 Nm

3000 = 125.22 Nm

6000 = 313 Nm

Standard and Euro:

1520 = 3.17 Nm

3520 = 73.46 Nm

5000 = 62.61 Nm

Comment